welding stick factories

The World of Welding Stick Factories

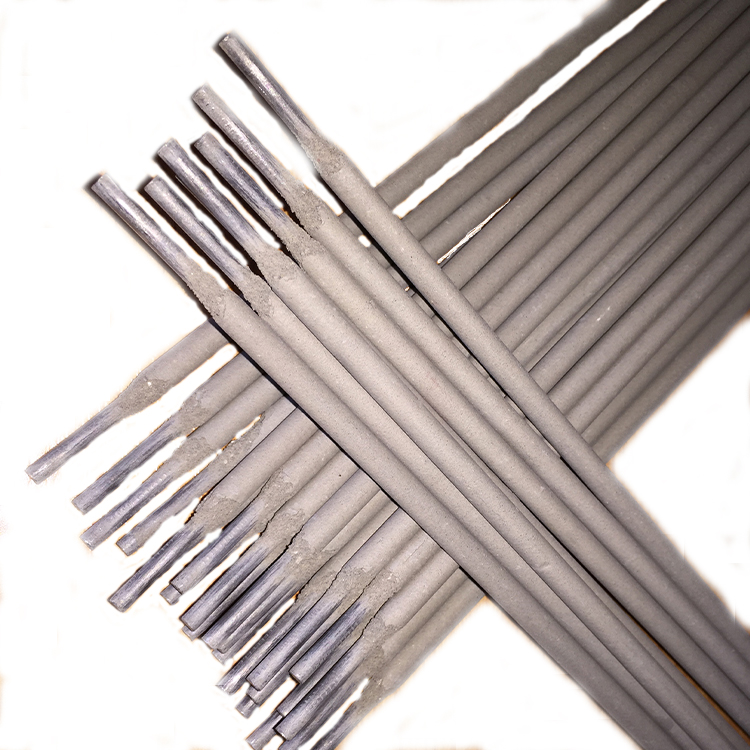

Welding, an integral part of modern manufacturing and construction, hinges on the quality and consistency of welding sticks, also known as electrodes. These tools facilitate the creation of strong joints between various metal pieces, making welding stick factories crucial players in various industries. This article delves into the importance of welding stick factories, their production processes, and the factors influencing their success.

The Significance of Welding Sticks

Welding sticks are essential for arc welding applications, where an electric current is used to melt and join metals. The quality of the welding stick directly impacts the strength and durability of the weld. Factors such as the stick's composition, coating, and diameter must be carefully considered during production. Low-quality welding sticks can lead to poor welds, resulting in structural failures and safety hazards.

Production Processes in Welding Stick Factories

The manufacturing of welding sticks involves several meticulous processes. First, the raw materials—typically a combination of metal powders, flux, and other additives—are acquired. Each component is critical; for instance, the flux helps protect the weld from contamination while controlling the properties of the molten pool.

Next comes the mixing stage, where the raw materials are combined in precise proportions to create a homogeneous mixture. This mixture is then shaped into sticks, often through processes such as extrusion or rolling. Extrusion is preferred for its ability to produce consistent diameters, while rolling can offer a different shape.

welding stick factories

After shaping, the welding sticks undergo a drying process to remove any excess moisture. This step is vital, as moisture can affect the performance of the welding stick during operation. Once dried, the sticks are coated with a protective layer to enhance their performance and prevent oxidation.

Finally, each batch of electrodes is rigorously tested to ensure it meets industry standards. Tensile tests, bend tests, and metallurgical examinations are common practices that confirm the quality and strength of the welding sticks. Only after passing these evaluations are the sticks packaged and shipped to customers around the globe.

Factors Influencing the Success of Welding Stick Factories

The success of welding stick factories is influenced by several key factors. First, technological advancements play a significant role. Factories that adopt cutting-edge manufacturing technologies often produce higher-quality products more efficiently. Automation and robotics are increasingly employed to enhance production capabilities and reduce human error.

Another factor is quality control. Factories that implement stringent quality assurance processes tend to build a strong reputation in the market, leading to increased customer trust and loyalty. Continuous feedback loops from customers can also inform production improvements, ensuring that the products meet the evolving demands of various applications.

Additionally, the global demand for welding sticks is influenced by economic trends. Industries such as construction, automotive, and shipbuilding are significant consumers of welding sticks, and fluctuations in these sectors can directly impact factory output.

In conclusion, welding stick factories play a pivotal role in modern manufacturing. By focusing on production quality, staying abreast of technological changes, and responding to market demands, these factories can ensure their continued success in a competitive industry. The importance of high-quality welding sticks cannot be understated, as they are essential to the integrity and safety of welded structures worldwide.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025