Manufacturing of Welding Wire Electrodes for Industrial Applications and Quality Assurance

The Importance of Welding Wire Electrodes Factories

Welding is a critical process in various industries, including construction, automotive, and manufacturing. At the heart of this process are welding wire electrodes, which play a pivotal role in ensuring strong and reliable welds. Factories specializing in the production of welding wire electrodes are essential to meet the growing demands of these industries.

Welding wire electrodes come in various types, including solid wire, flux-cored wire, and metal-cored wire. Each type serves specific applications and has unique properties that make it suitable for different welding techniques, such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and SMAW (Shielded Metal Arc Welding). The manufacturing of these electrodes involves a combination of advanced technologies and quality control processes that ensure high standards and performance.

The Importance of Welding Wire Electrodes Factories

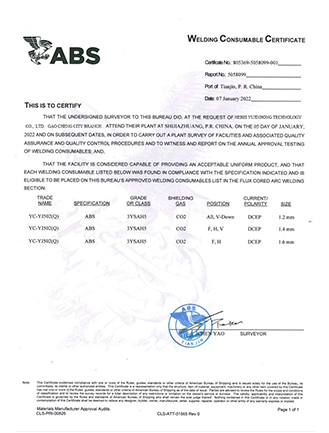

Quality control is paramount in the production of welding wire electrodes. Factories employ rigorous testing procedures to verify the chemical composition, tensile strength, and conductivity of the wires. Non-destructive testing methods, such as ultrasonic and magnetic particle inspections, are also utilized to ensure that the electrodes are free from defects. These measures guarantee that the final products meet industry standards and customer expectations.

welding wire electrodes factory

Furthermore, the demand for environmentally friendly solutions has led many welding wire electrodes factories to explore sustainable practices. This includes the use of recycled materials in the production process and energy-efficient manufacturing techniques. By adopting green practices, these factories not only reduce their environmental footprint but also appeal to clients who prioritize sustainability in their operations.

In addition to production, welding wire electrodes factories often offer technical support and training to their customers. This is vital in ensuring that end-users are fully equipped to use the products effectively. Knowledge sharing can include guidance on the selection of the right electrodes for specific applications, as well as best practices for welding techniques. Such support helps to enhance safety and productivity in the workplace, ultimately contributing to the quality of the final products.

The global market for welding wire electrodes continues to expand, driven by the increasing need for materials and structures that require robust joining solutions. Developing economies are rapidly industrializing, which in turn increases the demand for high-quality welding materials. As a response, factories are investing in the latest technologies and expanding their production capacities to stay competitive.

In summary, welding wire electrodes factories are essential players in the modern manufacturing landscape. Their commitment to quality, innovation, and sustainability not only enhances the welding process but also contributes to the overall efficiency and safety of various industries. As technology and market demands evolve, these factories must adapt and thrive, ensuring that they continue to provide superior welding solutions for years to come. With continued advancements and a focus on customer satisfaction, the future of welding wire electrodes production remains promising.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025