ER70S-6 Welding Wire Manufacturer for Reliable and High-Quality Welding Solutions

The Significance of ER70S-6 Welding Wire in Industrial Applications

Welding is a critical process in many manufacturing and construction industries, and the choice of welding filler material plays a significant role in achieving high-quality welds. One such material that has gained immense popularity among professionals is the ER70S-6 welding wire. This article delves into the characteristics, applications, and benefits of ER70S-6 welding wire, focusing on its importance in industrial settings.

Understanding ER70S-6

ER70S-6 is a type of solid welding wire used predominantly in gas metal arc welding (GMAW) and flux-cored arc welding (FCAW). The designation ER70S-6 can be broken down as follows

- E Electrode - R Rod or wire - 70 The minimum yield strength of the wire in thousands of pounds per square inch (psi)—in this case, 70,000 psi. - S Solid wire - 6 A classification indicating specific chemical composition and mechanical properties, particularly improved manganese and silicon levels.

The increased levels of these elements grant the wire enhanced arc stability and a better weld bead appearance, making it a preferred choice for many applications.

Characteristics of ER70S-6

1. Versatility One of the most notable features of ER70S-6 is its versatility. It can be used to weld various types of carbon steels, making it suitable for numerous industrial applications—including automotive, construction, and shipbuilding.

2. Excellent Mechanical Properties The wire delivers strong, ductile welds with excellent toughness and impact resistance. This makes it ideal for applications where weld integrity is critical.

3. Ease of Use ER70S-6 is easier to work with than many other filler materials. It has a smooth feeding characteristic that minimizes wire feeding issues during the welding process.

Applications of ER70S-6

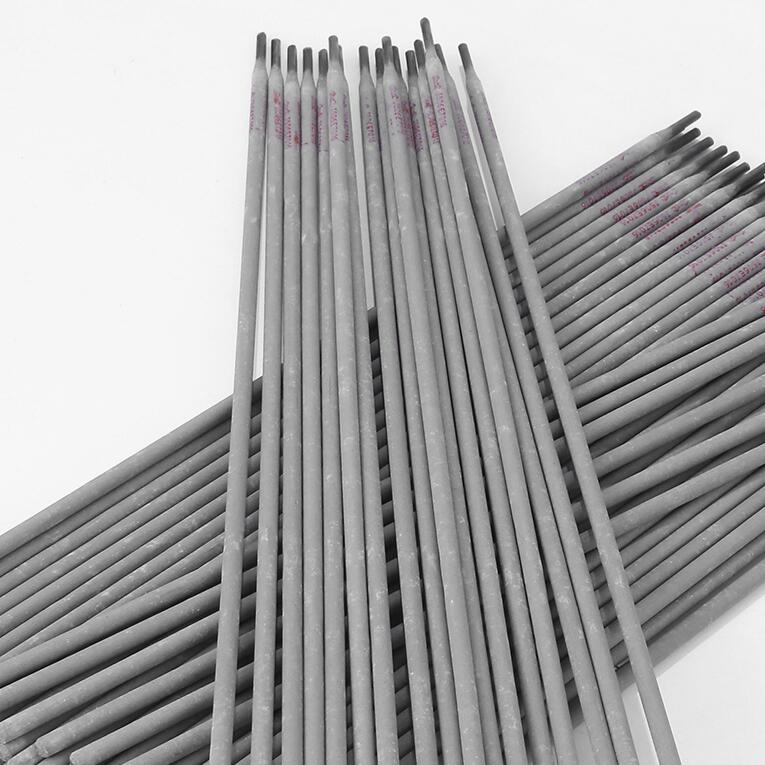

welding wire er70s 6 factory

The ER70S-6 welding wire is widely used in several industries, highlighting its versatility and effectiveness

- Heavy Fabrication Industries involved in heavy machinery and structural fabrication commonly utilize ER70S-6 due to its capacity to provide strong and reliable welds under challenging conditions.

- Automotive Industry In automotive manufacturing, ER70S-6 helps in the assembly of components that require strong and durable joints, particularly parts that undergo significant stress.

- Construction The construction sector benefits from the use of ER70S-6 in building structures and bridges, where the strength and durability of welds are paramount.

- Pipeline Welding This welding wire is an excellent choice in the oil and gas industry for pipeline welding applications, where it performs well in varying environmental conditions.

Benefits of Using ER70S-6 Welding Wire

1. High Quality of Welds The mechanical properties of ER70S-6 ensure that the welds produced are not only strong but also resistant to cracking and fatigue, essential attributes for safety-critical applications.

2. Cost-Effective Despite its high performance, ER70S-6 is often available at competitive prices, making it a cost-effective option for many manufacturers looking to optimize their production processes.

3. Improved Productivity The ease of use and excellent arc stability of ER70S-6 allows for faster welding operations, reducing downtime and increasing overall productivity.

4. Compatibility with Various Welding Processes ER70S-6 can be used in various welding processes, providing flexibility in welding operations and reducing the need for multiple filler materials.

Conclusion

In summary, ER70S-6 welding wire stands out as a fundamental component in the welding industry due to its versatile applications, outstanding mechanical properties, and cost-effectiveness. As industries continue to advance, the demand for high-quality welding materials like ER70S-6 will undoubtedly grow, further solidifying its reputation as a reliable choice for welders around the globe. Whether you are in automotive manufacturing, construction, or heavy fabrication, ER70S-6 is a welding wire that delivers exceptional results and contributes significantly to the integrity of welded structures.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025