Wholesale 1.2mm Tubular Welding Wire Suppliers for High-Quality Manufacturing and Competitive Pricing

Wholesale Tubular Welding Wire 1.2mm Key Insights for Buyers

In the realm of industrial welding, the choice of materials plays a pivotal role in determining the quality and efficiency of the final product. Among the most critical components is the welding wire, where tubular welding wire, specifically in a diameter of 1.2mm, has garnered notable attention. This article aims to provide insights into the wholesale market for 1.2mm tubular welding wire, focusing on factories that manufacture this essential product.

Understanding Tubular Welding Wire

Tubular welding wire is a type of welding filler material that is designed with a hollow structure. This unique configuration allows for the incorporation of various substances, such as flux, which can enhance welding performance and reduce spatter. The 1.2mm diameter is particularly popular among welders, as it strikes a balance between ease of handling and effective weld penetration, making it suitable for a wide range of applications, from automotive repair to construction projects.

Manufacturing Process and Quality Standards

Factories that produce tubular welding wire adhere to stringent quality standards to ensure that the final product meets industry requirements. The manufacturing process typically involves the following steps

1. Material Selection High-grade raw materials are chosen to ensure durability and performance. Common metals used include mild steel, stainless steel, and other alloys.

2. Wire Drawing The raw materials are drawn into thin wires, achieving the desired diameter of 1.2mm. This process involves mechanical reduction, which enhances the tensile strength of the wire.

3. Tubular Formation The drawn wires are then formed into a tubular shape. This is a crucial step as it allows for the infusion of flux and other additives.

4. Flux Filling The tubular wires are filled with pre-determined flux materials. This filler affects the welding arc characteristics and the quality of the weld.

5. Testing and Quality Assurance Before the welding wires are packaged for sale, they undergo rigorous testing, including tensile strength tests, chemical composition analysis, and performance assessments to ensure compliance with international standards.

wholesale tubular welding wire 1.2mm factories

Advantages of Purchasing Wholesale

Opting for wholesale tubular welding wire offers several advantages

1. Cost Efficiency Purchasing in bulk often leads to significant cost savings compared to retail prices. Wholesale factories usually provide competitive pricing models aimed at attracting large-volume buyers.

2. Consistent Supply For businesses that require a steady flow of welding materials, wholesale suppliers can ensure consistent availability, reducing the risk of project delays.

3. Customization Options Many factories offer customization in terms of flux composition and wire specifications, allowing buyers to select products tailored to specific welding applications.

4. Expertise and Support Established manufacturers often have teams of experts who can provide technical support and guidance on the best welding practices and material selections.

Selecting the Right Supplier

When choosing a factory for wholesale tubular welding wire, consider the following factors

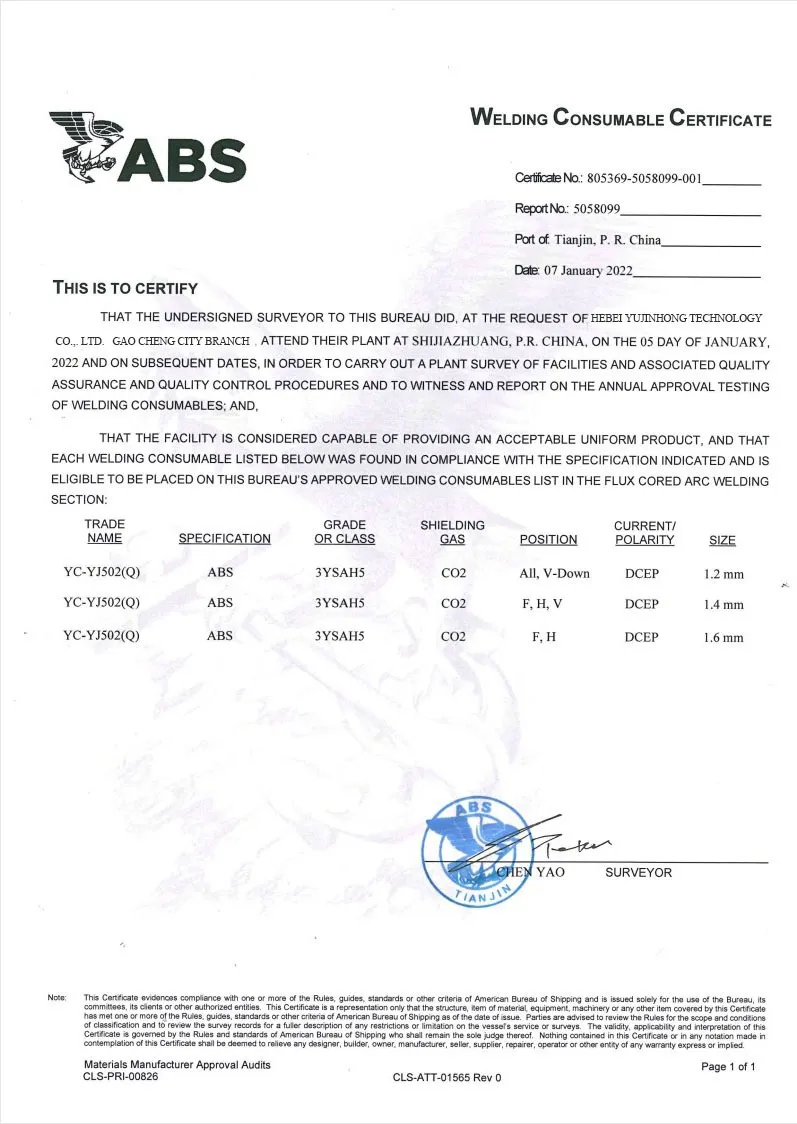

- Reputation and Experience Look for suppliers with a reliable track record and substantial experience in the industry. - Quality Certifications Ensure that the factory holds relevant quality certifications, such as ISO 9001. - Customer Service A responsive and knowledgeable customer service team can help address queries and assist in the ordering process. - Delivery Capabilities Evaluate the factory's ability to meet delivery timelines, especially for bulk orders.

Conclusion

The wholesale market for 1.2mm tubular welding wire plays a crucial role in various industries, providing essential materials for high-quality welding applications. With a keen understanding of the manufacturing process, the benefits of wholesale purchasing, and the criteria for selecting the right supplier, buyers can make informed decisions that enhance their welding operations. Investing in quality tubular welding wire can lead to improved efficiency, cost savings, and superior welding results in the long term.

-

E71T-GS Welding Wire: Versatile Flux Core for All-Position MIGNewsAug.31,2025

-

Premium Submerged Welding Wire: High Performance & ReliabilityNewsAug.30,2025

-

E7016 Welding Rods: High Strength Low Hydrogen for Critical WeldsNewsAug.29,2025

-

E71T-11 Flux Core Wire: Premium Gasless Welding SolutionNewsAug.28,2025

-

Premium Carbon Rods for Welding | Stable Arc & Precise GougingNewsAug.27,2025

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025