Wholesale Suppliers of 2 Gauge Welding Wire for Industrial and Commercial Applications

The Importance of Wholesale 202 Gauge Welding Wire Factories

In the realm of manufacturing and fabrication, welding is an essential process that binds various materials together, contributing to the integrity and strength of structures, machinery, and products. At the heart of this process lies the choice of welding wire. Among the various types available, the 202 gauge welding wire is one of the most sought-after materials due to its versatility, durability, and cost-effectiveness. As a result, wholesale 202 gauge welding wire factories have become increasingly important in meeting the demand for high-quality welding materials.

Understanding 202 Gauge Welding Wire

The term 202 gauge refers to the diameter of the welding wire, which is a critical factor in determining its suitability for various applications. Typically, the smaller the gauge number, the thicker the wire; however, 202 gauge denotes a specific thickness that balances flexibility and strength. This wire is commonly used in MIG (Metal Inert Gas) welding, one of the most popular welding techniques due to its speed and efficiency.

The composition of 202 gauge welding wire often includes materials such as stainless steel, carbon steel, or other alloys, depending on the desired properties for specific welding tasks. It is known for its excellent ability to resist corrosion and its capacity to produce strong welds that can withstand significant stress.

The Role of Wholesale Factories

Wholesale factories that specialize in 202 gauge welding wire play a pivotal role in the manufacturing ecosystem. These factories streamline production to cater to a variety of industries, such as construction, automotive, and shipbuilding, where reliable welding materials are a necessity. By producing in bulk, these factories can reduce costs, allowing them to offer competitive prices to their customers while maintaining high-quality standards.

Moreover, wholesale factories often emphasize customization. They can provide welding wire tailored to specific needs, including variations in diameter, material composition, and packaging options. This flexibility is crucial for businesses that require unique specifications for specialized projects.

wholesale 2 gauge welding wire factories

Quality Assurance and Compliance

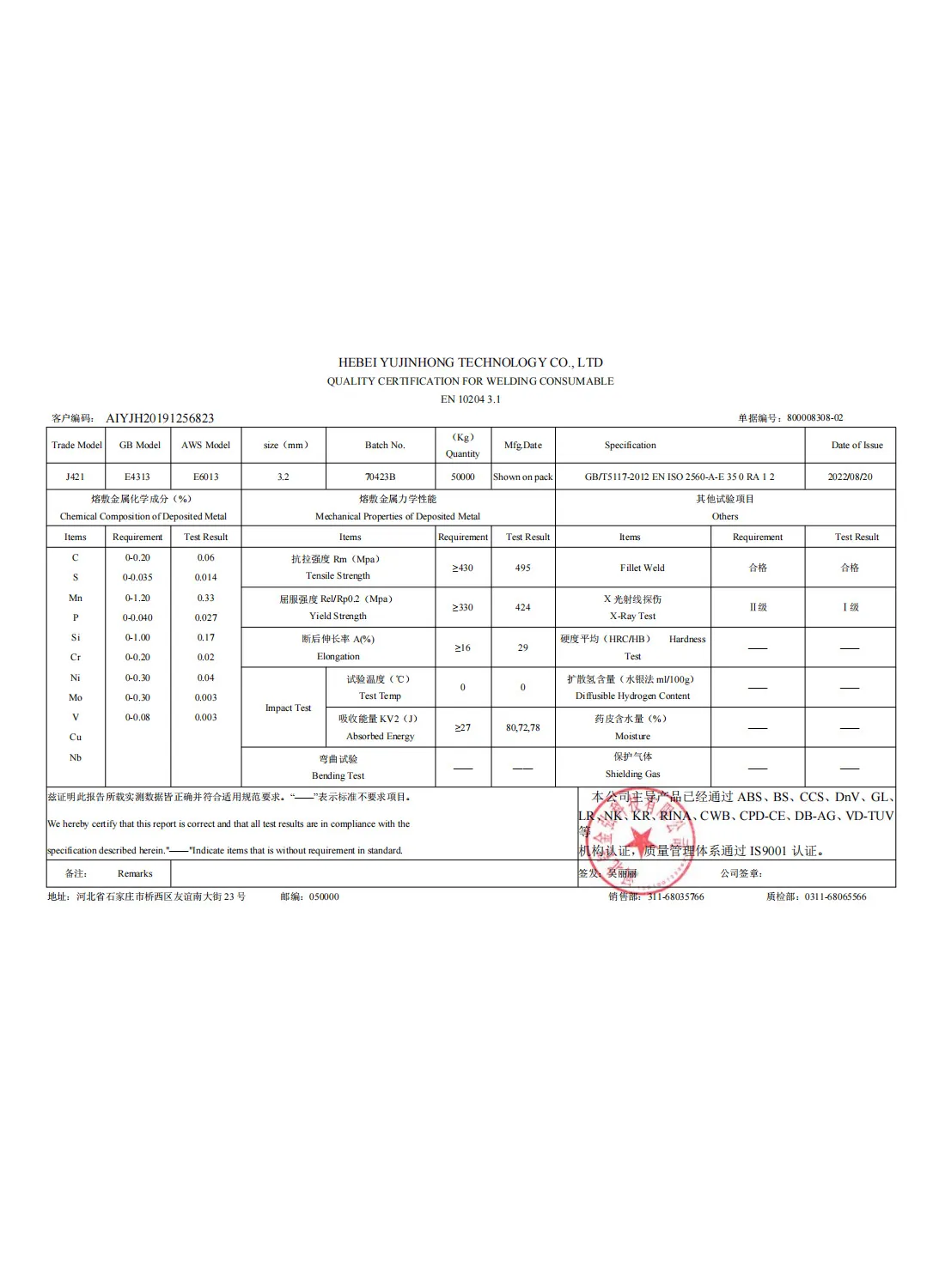

One of the primary concerns for any welding operation is the quality of the wire being used. Reputable wholesale 202 gauge welding wire factories prioritize quality assurance measures to ensure that their products meet industry standards and regulations. This often involves rigorous testing procedures, including tensile strength tests and corrosion resistance evaluations, to guarantee that the wire performs reliably under various conditions.

In addition to quality control, compliance with international standards, such as ISO and AWS (American Welding Society) regulations, is a hallmark of trustworthy manufacturers. These certifications not only reinforce the quality of the welding wire but also build confidence among customers in various sectors.

The Future of Wholesale Welding Wire

As industries continue to evolve, so does the demand for more sophisticated welding materials and techniques. Wholesale 202 gauge welding wire factories are adapting to these trends by investing in advanced manufacturing technologies, enhancing their production processes, and incorporating sustainable practices. This shift not only improves productivity but also aligns with global efforts towards environmental responsibility.

Furthermore, the rise of e-commerce has simplified the procurement process for businesses. Wholesale factories are increasingly establishing online platforms, enabling customers to order welding wire with ease and efficiency. This convenience, paired with competitive pricing and quality assurance, makes wholesale suppliers indispensable partners in any welding operation.

Conclusion

Wholesale 202 gauge welding wire factories are critical players in the manufacturing landscape, supporting various industries by providing high-quality and cost-effective welding materials. Their commitment to quality, customization, and compliance ensures they meet the evolving demands of modern welding applications. As these factories continue to innovate and adapt, they will undoubtedly remain essential to the success of welding operations worldwide.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025