wholesale 308l welding rod manufacturer

Understanding the Role of Wholesale 308L Welding Rod Manufacturers

In the dynamic world of welding, the materials utilized play a pivotal role in the quality and longevity of the final product. One such essential material is the welding rod, specifically the 308L welding rod, which is favored for its versatility and strength. Understanding the wholesale market for 308L welding rod manufacturers is crucial for industries that rely on welding for their production processes, shipbuilding, or construction projects.

What is 308L Welding Rod?

308L welding rods are a type of stainless steel filler rod, primarily composed of chromium and nickel. The designation L refers to the low carbon content of the rod, which is typically capped at 0.03%. This low carbon content minimizes the risk of carbide precipitation during welding, enhancing the corrosion resistance of the welded joint. Thus, 308L rods are particularly suitable for applications involving a variety of stainless steels, specifically austenitic stainless steels like 304.

The Importance of Wholesale Suppliers

For manufacturers and businesses involved in welding, sourcing high-quality materials at competitive prices is vital for maintaining product standards and profitability. Wholesale 308L welding rod manufacturers play a crucial role in this supply chain, offering bulk quantities at reduced prices. By dealing directly with wholesalers, businesses can save considerably, allowing them to invest those savings into other areas of their operations, such as expanding production capabilities or diversifying their product offerings.

Moreover, wholesale manufacturers often provide a diverse range of welding rods tailored to different applications. This variety can be pivotal for companies that need specific properties in their welding rods, such as improved ductility, strength, or resistance to high temperatures.

Quality Assurance

wholesale 308l welding rod manufacturer

When it comes to welding, quality assurance cannot be compromised. Wholesale 308L welding rod manufacturers are typically held to stringent industry standards and regulations. They must ensure that their products meet specific specifications, such as those set by the American Welding Society (AWS) and the International Organization for Standardization (ISO). This commitment to quality not only protects the integrity of the welding process but also ensures the safety and reliability of the end product.

Many reputable manufacturers invest in advanced technology and regular testing of their rods. This includes procedures such as tensile testing, impact testing, and microstructure analysis, all designed to assess the performance characteristics of the rods under various conditions. A reliable wholesale supplier will provide certifications and test reports, affirming the quality of their products.

Environmental Considerations

As industries worldwide move towards more sustainable practices, the role of wholesale welding rod manufacturers has evolved. Many manufacturers are now adopting environmentally friendly production processes, utilizing recycled materials and reducing waste. This shift not only helps in conserving natural resources but also aligns with the growing demand for sustainable and eco-friendly products in the market.

Building Strong Relationships

For businesses looking to source 308L welding rods, forming strong relationships with wholesale manufacturers can prove beneficial. Good communication and collaboration can lead to customized solutions, such as tailored specifications or rapid delivery options. This partnership can be advantageous for both parties, as manufacturers can gain insights into market demands, while businesses can enjoy a reliable supply of essential materials.

Conclusion

Wholesale 308L welding rod manufacturers play a fundamental role in the welding industry, providing quality materials essential for achieving strong and durable welds. Understanding the importance of these suppliers, alongside the quality and environmental standards they adhere to, empowers businesses to make informed purchasing decisions. In an industry where precision and reliability are paramount, partnering with reputable wholesalers can significantly impact the success of welding projects and overall operational efficiency. Subsequently, businesses can focus on delivering high-quality products, confident in the materials they are using. As the industry continues to evolve, the role of these manufacturers will undoubtedly remain critical in shaping the future of welding.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

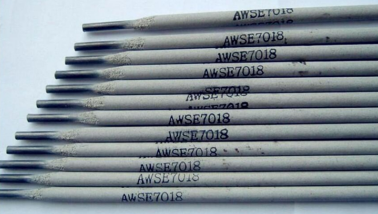

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025