wholesale 3.25mm welding electrodes factory

Wholesale 3.25mm Welding Electrodes A Comprehensive Guide

Welding is an essential process in various industries, including construction, manufacturing, and automotive. A crucial component of this process is the welding electrode, which serves as the filler material for welding joints. Among the various types and sizes available, 3.25mm welding electrodes have gained popularity due to their versatility and effectiveness. This article will explore the significance of wholesale 3.25mm welding electrodes, discussing their characteristics, applications, and factors to consider when purchasing from factories.

Understanding Welding Electrodes

Welding electrodes can be classified into two main categories consumable and non-consumable. Consumable electrodes melt during the welding process and contribute to the weld pool, while non-consumable electrodes do not melt and instead conduct electricity. The type of electrode chosen depends on the welding technique being used, such as MIG, TIG, or stick welding.

3.25mm welding electrodes fall into the category of stick welding (SMAW) electrodes. They are particularly suited for various welding tasks due to their optimal diameter, which balances ease of use with adequate penetration. This diameter is often preferred by professional welders and industries looking for reliability in their welding processes.

Characteristics of 3.25mm Welding Electrodes

The characteristics of 3.25mm welding electrodes can vary based on the material composition and coating. Generally, they come coated with a flux material that aids in shielding the weld pool from contaminants. This coating also assists in stabilizing the arc, making the welding process smoother and more efficient.

1. Material Composition Common materials for 3.25mm electrodes include mild steel, stainless steel, and cast iron. Each material serves specific applications, ensuring weld quality and strength.

2. Coating Types Electrodes can have different types of coatings, such as cellulose, rutile, or basic, each affecting the arc stability, slag appearance, and usability in various positions. For instance, rutile-coated electrodes are easier to use for beginners due to their forgiving nature.

3. Performance The performance of 3.25mm electrotypes can be assessed through their all-position welding capabilities, current range, and deposition rate, making them suitable for a wide range of tasks, from heavy-duty industrial work to automotive repairs.

Applications of 3.25mm Welding Electrodes

3.25mm welding electrodes find utility across diverse sectors. Their adaptability allows them to be used in applications such as

- Construction Used for joining structural components in buildings and infrastructure projects, where strength and durability are paramount.

wholesale 3.25mm welding electrodes factory

- Manufacturing Ideal for manufacturing equipment and machinery, ensuring welds can withstand operational pressures

.- Automotive Commonly utilized in vehicle repairs and fabrication, they provide a reliable means of joining metal parts.

- Maintenance and Repair Their versatility makes them suitable for routine maintenance tasks in workshops and industries, providing a quick solution for metal repairs.

Purchasing Wholesale 3.25mm Welding Electrodes from Factories

When considering wholesale purchases of 3.25mm welding electrodes, certain factors should be taken into account to ensure quality and reliability

1. Supplier Reputation Researching the supplier’s reputation can provide insights into the quality of their products. Look for reviews and testimonials from other customers.

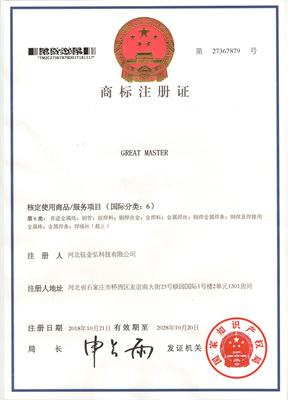

2. Certifications and Standards Ensure that the welding electrodes comply with industry standards and certifications. High-quality manufacturers usually adhere to standard specifications, ensuring their products meet the necessary safety and performance criteria.

3. Bulk Pricing Purchasing wholesale can often lead to significant cost savings. Compare pricing among various suppliers to find the best deal without compromising quality.

4. Technical Support A good supplier should offer technical assistance regarding the use and storage of welding electrodes, helping buyers make informed decisions.

5. Delivery and Logistics Timely delivery is essential for keeping projects on schedule. Choose a supplier that has a reliable logistics system in place.

Conclusion

Wholesale 3.25mm welding electrodes are vital for a myriad of applications across various industries. Their unique characteristics, coupled with the right supplier, can significantly enhance welding efficiency and quality. By understanding the importance of these electrodes and considering key purchasing factors, businesses can ensure they have reliable supplies for their welding needs. Whether you are part of a large construction firm or a small repair shop, investing in quality welding electrodes will undoubtedly pay off in the long run.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025