wholesale 3 4 welding electrode suppliers

Wholesale Welding Electrode Suppliers A Comprehensive Guide

Welding is an integral part of various industries, including construction, manufacturing, automotive, and repair services. Its effectiveness heavily relies on the quality of welding electrodes used. These electrodes serve as a filler material and provide the necessary heat to fuse metals together. As the demand for welding services continues to grow, so does the need for reliable wholesale welding electrode suppliers. This article explores the significance of wholesale welding electrodes, what to consider when choosing suppliers, and some of the best practices for purchasing.

The Importance of Welding Electrodes

Welding electrodes are vital in ensuring high-quality welds. They come in various types, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), and gas metal arc welding (GMAW) electrodes. Each type offers different properties suitable for specific applications, making it essential for businesses to stock a variety of electrodes. The quality of these electrodes not only affects the strength and durability of the weld but also has economic implications, as poor-quality electrodes can lead to increased labor costs due to rework and material wastage.

Choosing Wholesale Suppliers

When considering wholesale welding electrode suppliers, there are several factors to take into account to ensure you are making the best choice for your business

1. Quality Assurance The foremost consideration should be the quality of the electrodes. Suppliers should comply with industry standards such as AWS (American Welding Society) or ISO certifications. High-quality electrodes ensure better performance, which translates to less downtime and higher productivity.

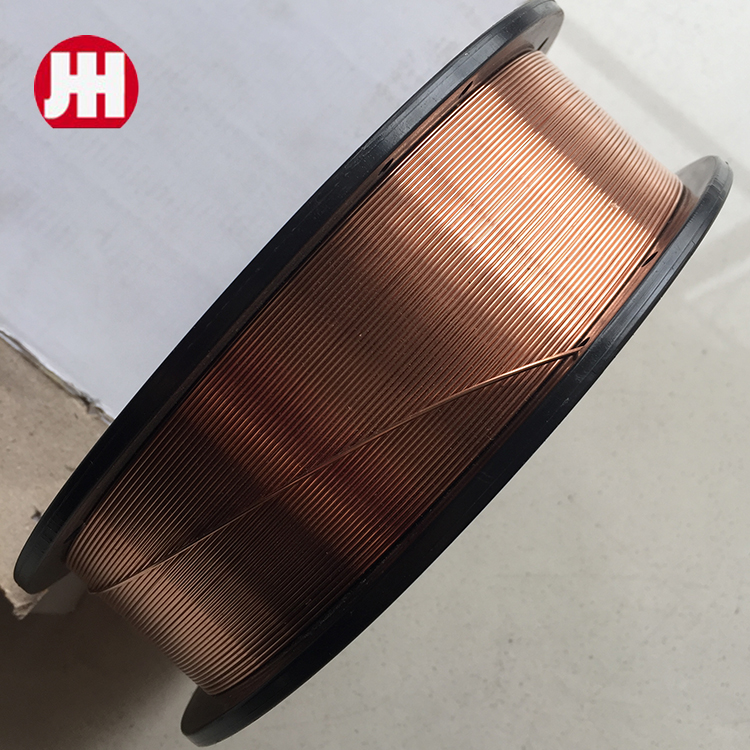

2. Product Range A good supplier should offer a wide range of welding electrodes to cater to various welding techniques and applications. Having access to different types of electrodes (such as flux-cored, solid wire, and specialty electrodes) allows businesses to be versatile in their welding operations.

3. Pricing Structure Analyze the pricing offered by different suppliers. While wholesale prices can be significantly lower than retail, it’s important to compare costs and ensure you’re getting a fair deal without compromising on quality. Look for bulk discounts or loyalty programs that can provide additional savings.

4. Customer Service Reliable customer service is crucial when dealing with suppliers. A supplier who can provide technical support, advice on electrode selection, and timely responses to inquiries can greatly enhance your purchasing experience.

wholesale 3 4 welding electrode suppliers

5. Delivery and Logistics Consider suppliers that offer reliable and timely shipping services. Delays in receiving welding electrodes can halt production processes, leading to loss of time and revenue. Efficient logistics are a key factor in maintaining operational effectiveness.

6. Reviews and Reputation Research the reputation of potential suppliers through customer reviews or testimonials. A supplier renowned for their reliability and service can save your business significant trouble in the long run.

Best Practices for Purchasing

Once you have selected your suppliers, implementing best practices for purchasing can further optimize your procurement process

- Establish Relationships Build a good rapport with your suppliers. Strong relationships often lead to better pricing, improved service, and the ability to negotiate custom orders.

- Keep an Inventory Maintain an adequate inventory of welding electrodes to avoid interruptions in projects. Having a systematic approach to inventory management helps in tracking usage and reorder points.

- Stay Informed The welding industry is constantly evolving with new technologies and materials. Stay updated with the latest news, practices, and products to ensure that you are making informed decisions.

- Evaluate Regularly Regularly assess your suppliers to ensure they meet your ongoing needs and standards. If any issues arise regarding quality or service, it’s crucial to address them promptly.

Conclusion

Wholesale welding electrode suppliers play a pivotal role in the success of any welding operation. By understanding the key factors to consider when selecting suppliers and incorporating best practices for purchasing, businesses can ensure efficiency, quality, and ultimately, profitability. As industries continue to evolve, maintaining a strong supply chain for welding materials will remain essential for staying competitive.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025