wholesale aluminum flux cored welding wire factory

Understanding Wholesale Aluminum Flux Cored Welding Wire Manufacturing and Benefits

In the world of welding, particularly when it comes to aluminum, the choice of materials is crucial to the success and quality of a project. Among the various options available on the market, wholesale aluminum flux cored welding wire has gained popularity due to its numerous advantages. This article will delve into the manufacturing process, applications, and benefits of this innovative welding wire.

What is Flux Cored Welding Wire?

Flux cored welding wire is a type of welding filler material that contains a core of flux. The purpose of the flux is to help protect the weld from atmospheric contamination, improve the flow of molten metal, and enhance the overall quality of the weld. In the case of aluminum flux cored welding wire, this specialized wire is designed specifically for welding aluminum and its alloys, making it an essential product for many industrial applications.

Manufacturing Process

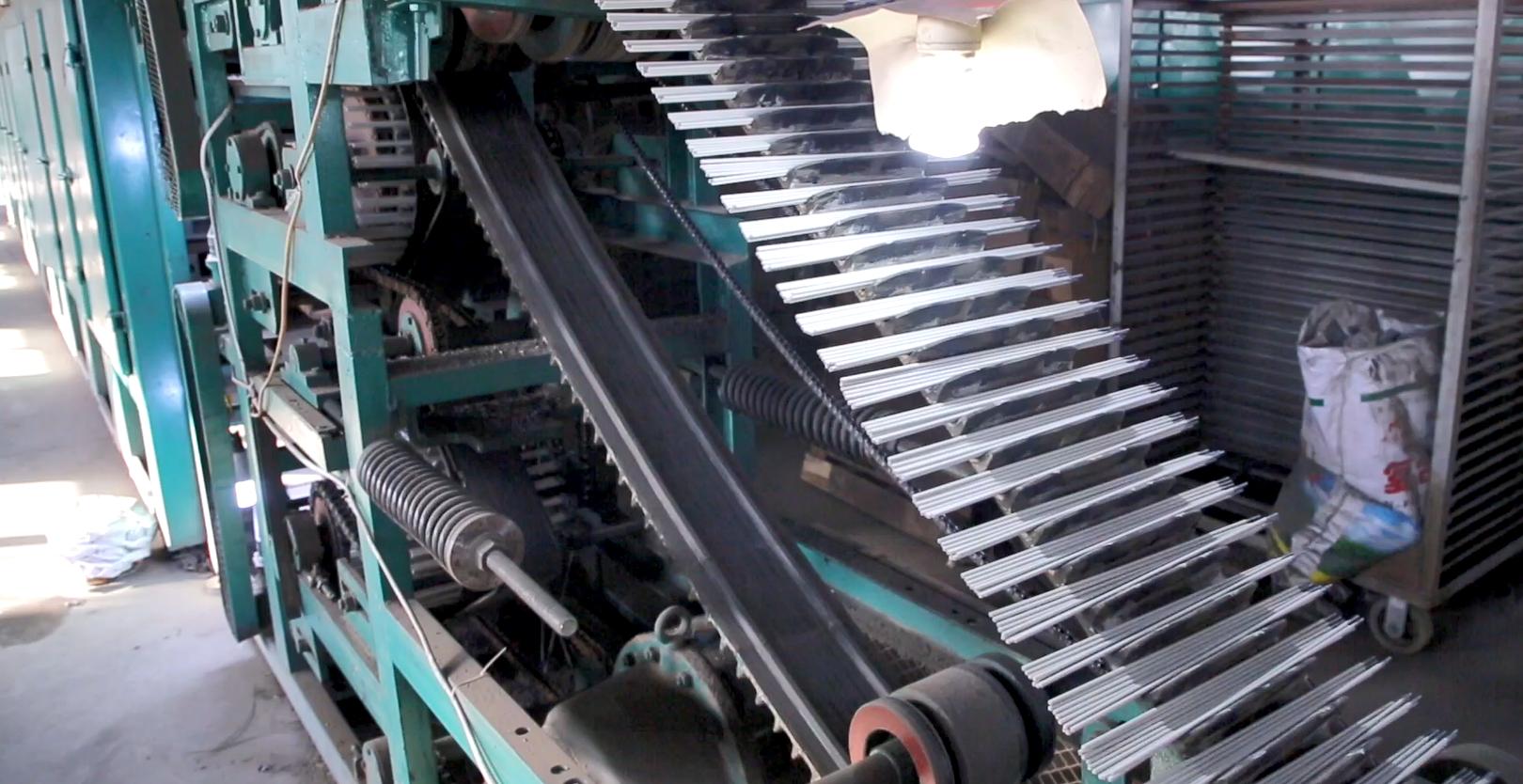

The manufacturing of aluminum flux cored welding wire involves several steps, starting from the selection of high-quality aluminum and flux materials. Manufacturers usually utilize advanced techniques to ensure that the wire meets strict industry standards and specifications.

1. Raw Material Selection The first step is the careful selection of aluminum alloy and flux materials that best suit the intended applications. This is crucial as different compositions can significantly affect the welding properties.

2. Wire Drawing The selected aluminum is drawn into thin wire through a series of dies, which reduces the diameter of the wire and ensures consistency in size, an essential factor for optimal welding performance.

3. Flux Filling Once the aluminum wire is produced, the flux material is introduced into the core of the wire. This is done under controlled conditions to ensure a uniform distribution of flux throughout the wire, which is vital for achieving a quality weld.

4. Welding Process Assessment After manufacturing, the wire undergoes a series of tests to assess its welding performance. These tests are essential to identify any defects and guarantee that the wire meets the required standards.

wholesale aluminum flux cored welding wire factory

5. Packaging Finally, the wire is packaged for wholesale distribution. Proper packaging is critical to prevent damage during shipping and to ensure that the product remains viable for use upon arrival.

Benefits of Using Aluminum Flux Cored Welding Wire

1. Enhanced Weld Quality One of the primary benefits of using aluminum flux cored welding wire is the superior quality of the welds produced. The flux core helps to protect the molten metal, reducing the likelihood of defects such as porosity and contamination.

2. User-Friendly This type of welding wire is particularly user-friendly for welders, including those who may not have extensive experience with aluminum. The self-shielding nature of the wire simplifies the welding process, making it easier to produce consistent, high-quality welds.

3. Versatility Aluminum flux cored welding wire is compatible with a variety of aluminum alloys, allowing it to be used in diverse applications across industries such as automotive, aerospace, and construction.

4. Cost-Effective Purchasing in wholesale quantities can lead to significant cost savings for welding companies. Additionally, the reduced need for post-weld finishing and repairs due to the high-quality welds produced can result in lower overall project costs.

5. Improved Productivity The ability to achieve satisfactory results with fewer passes can improve productivity on the job site. This efficiency is an essential factor in meeting tight deadlines in competitive industries.

Conclusion

In summary, wholesale aluminum flux cored welding wire represents a crucial advancement in the welding sector. With its optimized manufacturing process, outstanding weld quality, and various benefits, it has become an essential component for welders working with aluminum. By choosing the right supplier and product, welding professionals can enhance their operations, achieve superior results, and maintain a competitive edge in their respective markets.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025