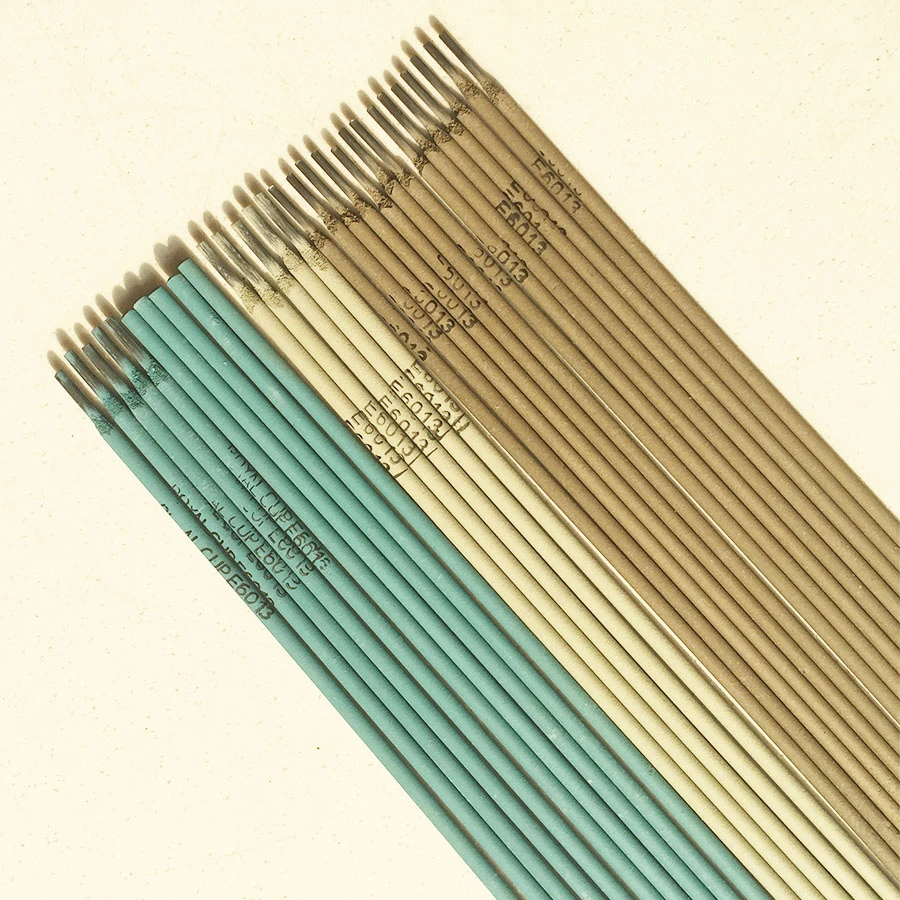

wholesale arc welding electrodes factories

Wholesale Arc Welding Electrodes An Overview of Factories and Their Importance

Arc welding, a pivotal technique in the metal fabrication industry, relies heavily on high-quality electrodes to achieve optimal results. As industries globally continue to expand, the demand for wholesale arc welding electrodes has surged. This article delves into the factories that manufacture these essential products, exploring their importance in ensuring the efficacy of welding operations.

Understanding Arc Welding Electrodes

Arc welding is a process that uses electrical energy to melt and fuse metals together. The electrodes used in this process conduct electricity and provide the filler material necessary for the weld. They come in various types, including consumable and non-consumable electrodes, each designed to meet specific welding requirements. The quality of these electrodes directly influences the integrity of the weld, making it crucial for manufacturers to maintain stringent quality control measures.

The Role of Factories in the Production of Electrodes

Factories specializing in the production of arc welding electrodes are equipped with advanced technology and skilled personnel. These facilities focus on several key aspects of electrode manufacturing

1. Raw Material Sourcing High-quality electrodes require superior raw materials, which can include metals, alloys, and specialized coatings. Factories work closely with suppliers to ensure they source materials that meet industry standards.

2. Manufacturing Processes The production of welding electrodes involves several stages, including forming, drawing, and coating. Factories utilize sophisticated machinery and techniques to produce electrodes that are consistent in quality and performance.

wholesale arc welding electrodes factories

3. Quality Control To meet the demands of the welding industry, factories implement rigorous testing methodologies. This includes checking for dimensional accuracy, tensile strength, and performance under various welding conditions. Adherence to international standards such as ISO and AWS ensures that the products deliver reliability and safety in application.

4. Research and Development Innovation is paramount in electrode manufacturing. Factories invest in R&D to develop new electrode formulations that enhance performance, increase durability, and reduce environmental impact. This could involve the development of electrodes that work well with different welding methods or those that provide better arc stability.

The Importance of Wholesale Suppliers

Wholesale suppliers play a crucial role in the distribution of arc welding electrodes. By purchasing in bulk, manufacturers and welding companies can significantly reduce costs. This not only makes it more affordable for smaller businesses to access high-quality electrodes but also ensures that larger operations have a steady supply for continuous production.

Moreover, wholesalers often provide additional services, such as packaging, logistics, and sometimes even technical support. This comprehensive approach allows welding firms to focus on their core activities while ensuring they have the necessary materials on hand.

Conclusion

As industries evolve, so does the arc welding sector. The factories that produce wholesale arc welding electrodes are indispensable, as they provide the backbone of quality and reliability needed in welding applications. With a commitment to innovation, quality control, and customer service, these manufacturers not only enhance the efficiency of welding processes but also contribute to the overall development of the industry.

In a world where construction, manufacturing, and fabrication are continually advancing, the significance of reliable welding electrodes cannot be overstated. Those who invest in quality electrodes from reputable wholesale suppliers can ensure their projects uphold standards of excellence and safety. As the market continues to grow, the focus will inevitably shift towards finding sustainable and highly effective electrode solutions, further highlighting the importance of factories dedicated to this critical aspect of welding technology.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025