Top Wholesale Manufacturers for Quality MIG Welding Wires in the Market

The Best Wholesale MIG Wire Factories A Comprehensive Overview

In the realm of welding, MIG (Metal Inert Gas) welding is widely recognized for its efficiency, versatility, and ease of use. As such, the demand for high-quality MIG wires has surged, prompting several factories across the globe to specialize in their production. This article delves into the best wholesale MIG wire factories, highlighting their unique features, capabilities, and contributions to the welding industry.

Understanding MIG Wire

MIG wire is a consumable electrode used in the MIG welding process. It is made from various metals, primarily steel or aluminum, and is often coated with a layer of deoxidizers or other materials to improve performance. The choice of MIG wire significantly influences the quality of the weld, making it essential for welders and manufacturers to source their materials from reputable suppliers.

Key Characteristics of Top-tier Wholesale Factories

1. Quality Control The best MIG wire factories prioritize stringent quality control measures throughout their production processes. They employ advanced testing techniques to ensure that the wire meets or exceeds industry standards. Whether it’s tensile strength, elongation, or purity, quality assurance remains a non-negotiable aspect of their operations.

2. Variety of Products Leading factories often offer a wide range of MIG wires to cater to different welding applications. This includes different diameters, compositions (such as ER70S-6 for mild steel or ER4047 for aluminum), and spooling options. The diversity in product offerings allows customers to find the perfect fit for their specific welding needs.

3. Affordable Pricing Wholesale factories allow businesses to purchase MIG wires in bulk, thus significantly reducing costs. By optimizing production techniques and sourcing raw materials efficiently, these factories are able to pass on savings to their customers, making quality welding materials more affordable.

wholesale best mig wire factories

4. Innovative Manufacturing Techniques Many top factories invest in research and development to improve their manufacturing processes. Automation, advanced metallurgy, and environmentally-friendly production techniques are becoming hallmarks of successful MIG wire manufacturers. These innovations not only enhance the quality of the wire but also reduce environmental impact.

5. Customer Support and Services The best wholesale MIG wire factories understand that customer satisfaction is crucial for maintaining long-term relationships. They offer excellent customer support, from technical guidance on wire selection to logistics in delivering products efficiently. Many also provide training and resources to help end-users maximize the performance of their welding equipment and materials.

Notable Factories Around the World

Some renowned MIG wire factories that have established a strong reputation in the industry include

- Esab A global leader in welding and cutting technologies, Esab produces high-grade MIG wires used in various applications, from industrial to DIY projects.

- Lincoln Electric Known for their innovative welding equipment and consumables, Lincoln Electric is a major player in the MIG wire market, offering a comprehensive range of products.

- Hobart Specializing in welding and cutting solutions, Hobart is committed to providing high-quality MIG wires tailored to meet industry standards.

In conclusion, when sourcing MIG wires for wholesale purposes, it is crucial to consider the quality, variety, pricing, and customer support offered by factories. Establishing partnerships with reputable manufacturers not only ensures the reliability of the products but also enhances the overall efficiency and quality of the welding process. As the demand for MIG welding continues to grow, so too does the importance of these factories in shaping the industry's future.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

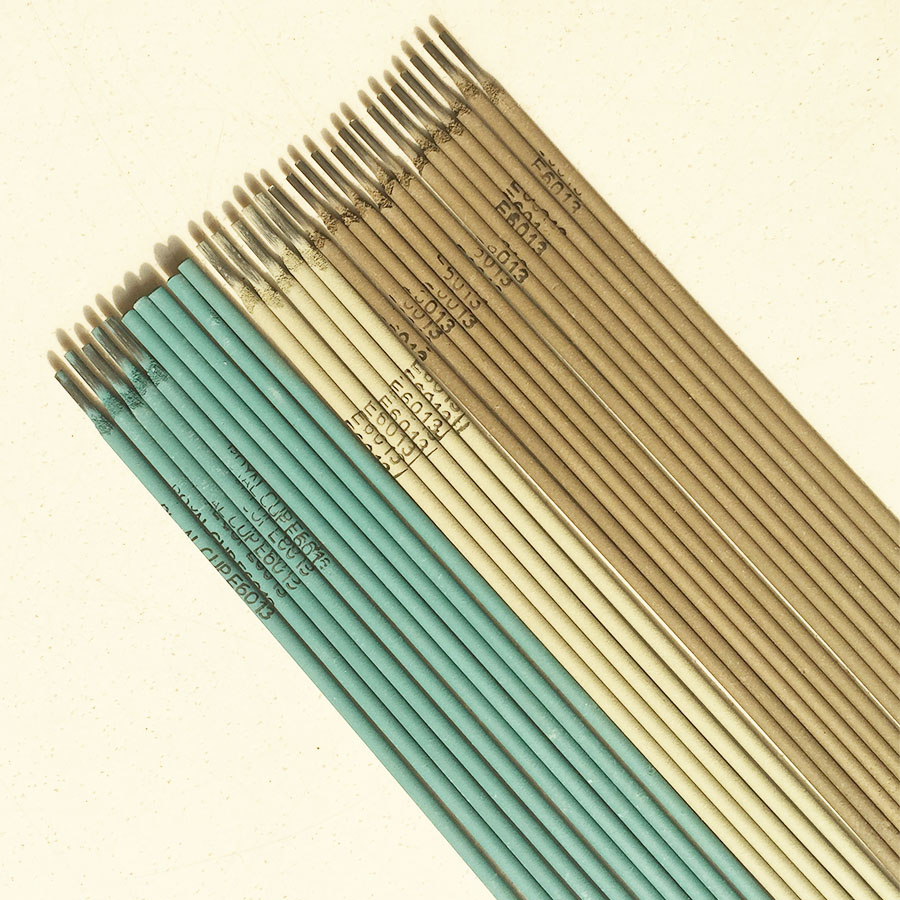

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025