wholesale best welding rod for cast iron factory

The Best Welding Rods for Cast Iron A Comprehensive Guide for Factories

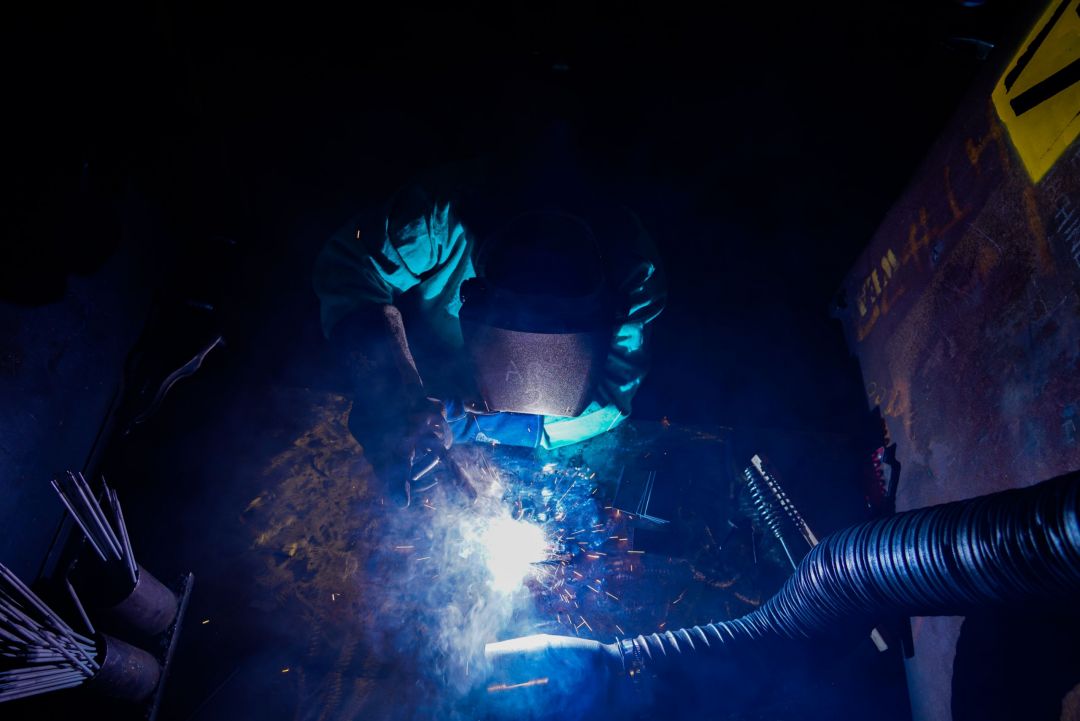

Welding cast iron can be a challenging task due to its unique properties and composition. Cast iron is characterized by its high carbon content, which makes it brittle and difficult to weld compared to other metals. Therefore, selecting the right welding rod is crucial for ensuring strong, durable welds. In this article, we will explore the best welding rods for cast iron, focusing on factors like material compatibility, welding techniques, and specific product recommendations that factories can implement.

Understanding Cast Iron

Cast iron is a group of iron-carbon alloys with a carbon content that typically exceeds 2%. This high carbon content contributes to its hardness and brittleness. Cast iron is widely used in various applications, from manufacturing engine blocks to household cookware. However, its welding requires special consideration due to its susceptibility to cracking and distortion during the welding process.

Types of Welding Rods for Cast Iron

When it comes to welding cast iron, there are several types of rods you can consider

1. Stainless Steel Electrodes These rods can be effective for welding cast iron as they create a strong joint that can withstand thermal cycling. They are particularly useful for high-stress applications although they can lead to some linear expansion differences that may cause warping if not managed properly.

2. Nickel Rods Nickel-based welding rods are commonly used for cast iron welding. They provide excellent ductility and impact resistance, making them ideal for applications where the welded piece will be subjected to heavy use. Nickel can also help mitigate the possibility of cracks in the weld, which is crucial for cast iron.

3. Graphite and Other Special Alloys Some rods are specifically designed to handle the unique challenges presented by cast iron. These may include rods that incorporate a mixture of materials, including nickel and cobalt, to provide the necessary strength and flexibility.

Selecting the Right Welding Rod

Choosing the correct welding rod depends on multiple factors, including the specific type of cast iron being welded (gray, ductile, malleable, etc.), the assembly's anticipated stress levels, and environmental conditions. Here are a few considerations for factory settings

wholesale best welding rod for cast iron factory

- Welding Method Different methods (TIG, MIG, stick welding) may require different types of rods. Stick welding (SMAW) is often preferred for cast iron due to its simplicity and effectiveness in various positions.

- Preparation of the Base Material Properly cleaning the cast iron surface to remove any contaminants like rust, oil, or dirt is essential for achieving a strong bond. Preheating the material before welding can also help reduce the risk of cracking.

- Post-Welding Treatment After welding, it’s crucial to cool the welded area gradually to avoid rapid thermal contraction, which can lead to cracking. Stress-relieving heat treatments may also be beneficial.

Recommended Products for Factories

Here are a few recommended welding rods that factories can consider for welding cast iron

1. Lincoln Electric Nickel Alloy Electrodes These electrodes are designed specifically for welding cast iron and are known for their superior strength and ductility. They are suitable for various applications and are a favorite among welders.

2. Hobart Nickel 55 Rod This rod is another excellent option, providing good performance with ductile cast iron. It's well-regarded for its ease of use and compatibility with all welding positions.

3. ESAB 309L Stainless Steel Electrodes While not a nickel rod, the ESAB 309L can be effectively used to weld cast iron due to its unique properties, offering a good balance between strength and weldability.

Conclusion

Welding cast iron in a factory environment requires careful consideration of the type of welding rods used. Selecting the appropriate rod can significantly impact the quality and durability of the weld. While nickel rods are frequently the best choice due to their flexibility and strength, options like stainless steel electrodes and specially designed alloy rods can also be beneficial depending on the unique application requirements. By understanding the properties of cast iron and adhering to best practices in welding, factories can ensure successful outcomes for their cast iron projects, maintaining product integrity and minimizing unnecessary costs.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025