wholesale co2 solid welding wire manufacturer

Wholesale CO2 Solid Welding Wire Manufacturer Ensuring Quality and Reliability in Welding Solutions

In the ever-evolving world of welding technology, CO2 solid welding wire has established itself as a preferred choice for many industries due to its efficiency and effectiveness in performing high-quality welds. The demand for reliable welding materials has led to a surge in wholesale CO2 solid welding wire manufacturers, each vying to meet the needs of diverse sectors such as automotive, construction, shipbuilding, and more. This article delves into the significance of these manufacturers, the advantages of CO2 solid welding wire, and what to look for when choosing a supplier.

Importance of CO2 Solid Welding Wire

CO2 solid welding wire is primarily used in gas metal arc welding (GMAW), also known as MIG welding. The process involves feeding a continuous wire electrode into the welding gun, where it melts and joins the base metals. CO2 gas is used as a shielding gas to protect the molten weld pool from atmospheric contamination, ensuring a strong bond between materials.

The use of CO2 solid welding wire comes with numerous advantages

1. Excellent Penetration One of the standout features of CO2 welding is its deep penetration capability. This allows welders to achieve solid and durable welds even on thicker materials, minimizing the risk of defects like porosity and incomplete fusion.

2. Cost-Effectiveness Compared to other shielding gases, CO2 is relatively inexpensive. This makes CO2 solid welding wire an economical choice without compromising on quality, especially for large-scale manufacturing and fabrication projects.

3. Versatility CO2 solid welding wire works well on a variety of materials, including carbon steel and some stainless steel, making it suitable for multiple applications across different industries.

4. Stable Arc and Minimal Spatter Welds produced with CO2 solid welding wire tend to have a stable arc, resulting in less spatter and easier post-weld cleanup. This characteristic is particularly valuable in settings where speed and cleanliness are crucial.

wholesale co2 solid welding wire manufacturer

Choosing the Right Wholesale Manufacturer

Selecting a reliable wholesale CO2 solid welding wire manufacturer is essential for ensuring that you receive high-quality products that meet industry standards. Here are some key factors to consider

1. Quality Assurance Look for manufacturers who adhere to international quality standards such as ISO 9001. This certification indicates that the manufacturer follows stringent quality control measures throughout the production process.

2. Material Specifications Ensure that the welding wire produced meets relevant specifications, such as AWS (American Welding Society) classifications. This guarantees that the wire is designed to perform well under various conditions and applications.

3. Production Capabilities Assess the manufacturer’s production capacity to ensure they can meet your supply demands, whether you require small batches or bulk orders. A manufacturer with advanced machinery and technology will be better equipped to deliver consistent quality.

4. Technical Support Partnering with a manufacturer that offers technical support can be invaluable. This includes assistance with product selection, welding parameters, and troubleshooting, contributing to more efficient operations.

5. Reputation and Reviews Research the manufacturer’s reputation within the industry. Customer reviews and testimonials can provide insights into their reliability, product quality, and service.

Conclusion

The role of wholesale CO2 solid welding wire manufacturers is crucial in providing industries with the necessary tools to perform effective welding tasks. With the advantages of CO2 solid welding wire, including cost-effectiveness, excellent penetration, and versatility, manufacturers are helping to push the boundaries of welding technology. By choosing the right supplier that prioritizes quality, production capacity, and customer support, businesses can ensure they have the optimal resources to succeed in their welding projects. As the industry continues to grow, investing in reliable materials will remain a cornerstone of welding excellence.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

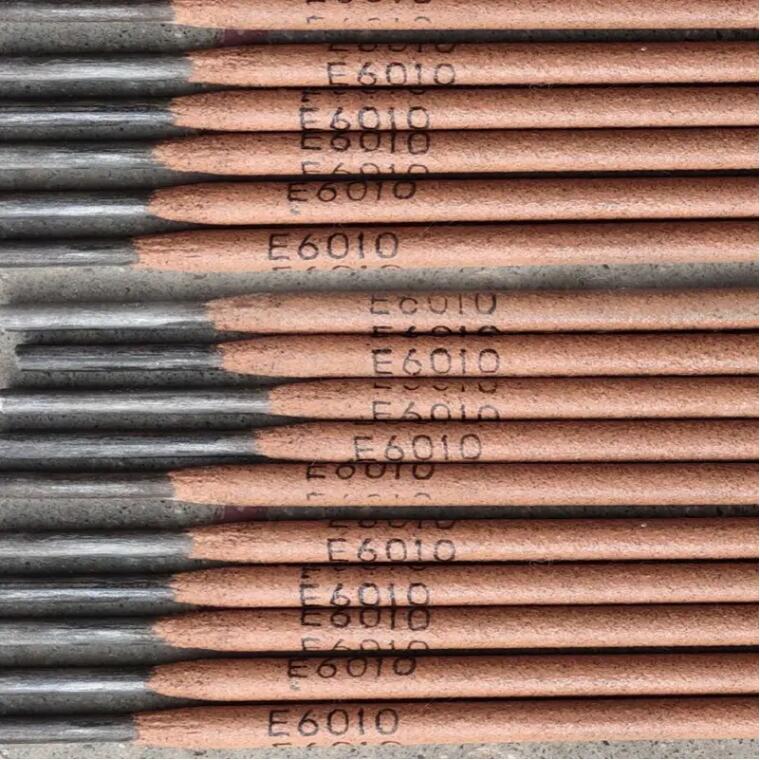

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025