wholesale er70s-6 .035 mig wire supplier

Understanding ER70S-6 .035 MIG Wire A Supplier's Perspective

In the world of welding, selecting the right materials is critical to achieving high-quality results. One of the most popular choices among professionals and hobbyists alike is ER70S-6 .035 MIG wire. This wire, known for its versatility and excellent performance, is particularly sought after by those in the fabrication and welding industries. In this article, we will delve into the characteristics of ER70S-6 .035 MIG wire and what to consider when sourcing it from suppliers.

What is ER70S-6 .035 MIG Wire?

ER70S-6 is a silicon and manganese alloyed wire designed for welding carbon steel and certain low-alloy steels. The ER denotes that it is an electrode rod, while 70 indicates the minimum yield strength of the weld metal in thousands of pounds per square inch (psi). The S signifies a solid wire, and the -6 implies that this wire has additional deoxidizers, making it suitable for welding in various conditions, including those where rust or scale are present.

The .035 designation refers to the diameter of the wire, which is 0.035 inches. This size is particularly favored for its balance between ease of handling and strength, making it ideal for both thin and medium-thick materials.

Advantages of ER70S-6

.035 MIG WireOne of the key benefits of ER70S-6 .035 MIG wire is its ability to produce strong, structurally sound welds with a smooth finish. The deoxidizers in this wire help to prevent oxidation during the welding process, resulting in cleaner, higher-quality welds. Furthermore, its compatibility with various shielding gases, including argon and CO2 mixtures, enhances its usability across different welding applications.

Sourcing ER70S-6 .035 MIG Wire

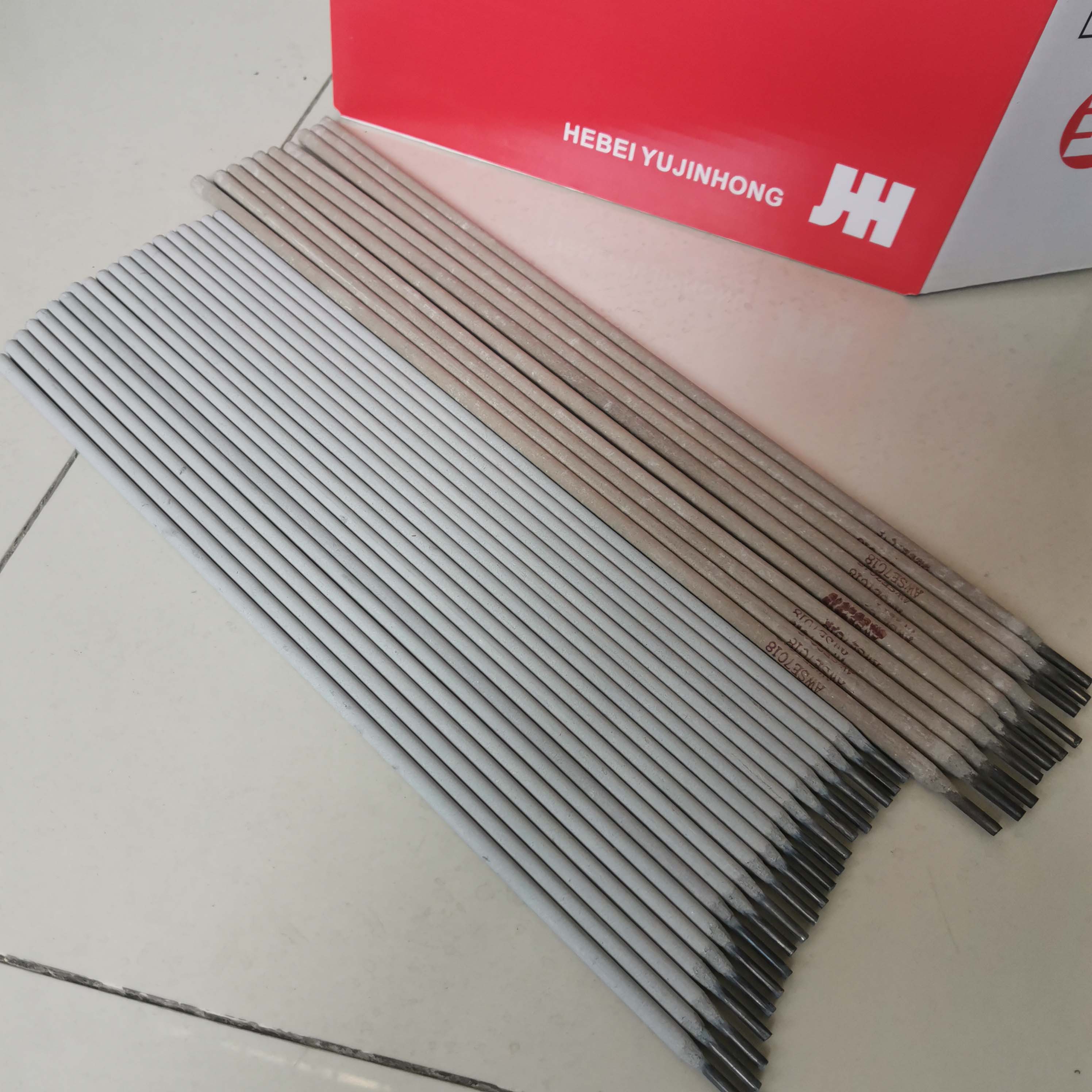

wholesale er70s-6 .035 mig wire supplier

When it comes to sourcing ER70S-6 .035 MIG wire, working with a reliable wholesaler is paramount. Here are some factors to consider during your search for the right supplier

1. Quality Assurance Ensure that the wire meets industry standards and is certified by relevant regulatory bodies. Quality assurance can often be verified through product certifications or third-party testing.

2. Pricing and Bulk Discounts Evaluate the pricing structure of different suppliers. Many wholesalers offer bulk discounts, which can significantly reduce costs for businesses that require large quantities of welding wire.

3. Availability and Delivery Consider the availability of the wire and the supplier's delivery timelines. A good supplier should be able to quickly meet your demands and provide consistent inventory levels.

4. Customer Service Effective communication and support from the supplier can facilitate smoother transactions and help address any issues that arise during the procurement process.

5. Reputation and Reviews Research the reputation of potential suppliers by examining customer reviews and testimonials. A supplier with a strong track record is often a safer choice.

Conclusion

ER70S-6 .035 MIG wire is a favored choice in the welding industry due to its excellent performance and adaptability to various applications. By choosing a reputable supplier, businesses can ensure they are getting high-quality materials that meet their specific welding needs, ultimately leading to enhanced performance and efficiency in their projects. Investing time to find the right supplier can make all the difference in achieving superior welding results.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025