Top ER70S Welding Wire Manufacturers for Wholesale Supply and Quality Assurance

Overview of Wholesale ER70S Welding Wire Manufacturers

In the welding industry, the choice of materials plays a crucial role in determining the quality and efficiency of the welding process. One of the most commonly used welding wires is the ER70S series, renowned for its strong performance in various applications, particularly in mild steel welding. As the demand for high-quality welding consumables continues to grow, the role of wholesale ER70S welding wire manufacturers has become increasingly significant.

Understanding ER70S Welding Wire

The ER70S welding wire is a solid wire that is typically used in gas metal arc welding (GMAW) processes. The ER stands for Electrode Rod, while 70 indicates the minimum tensile strength of the weld deposit, which is 70,000 psi, and the S signifies that it is a solid rod. The wire is made from a combination of iron, carbon, and other alloying elements that enhance its performance in various welding conditions. The excellent arc stability, low spatter particles, and capacity for providing high-quality welds make ER70S a preferred choice among welders.

The Importance of Wholesale Manufacturers

Wholesale manufacturers of ER70S welding wire play a pivotal role in supplying the welding industry. They provide a vital link between production and end-users, ensuring that large quantities of welding wire are readily available for construction companies, shipbuilding industries, and automotive manufacturers, among others. These manufacturers typically offer products in bulk, reducing costs for their clients and streamlining the procurement process.

Key Features to Look for in Manufacturers

When searching for wholesale ER70S welding wire manufacturers, several key features should be considered

wholesale er70s welding wire manufacturers

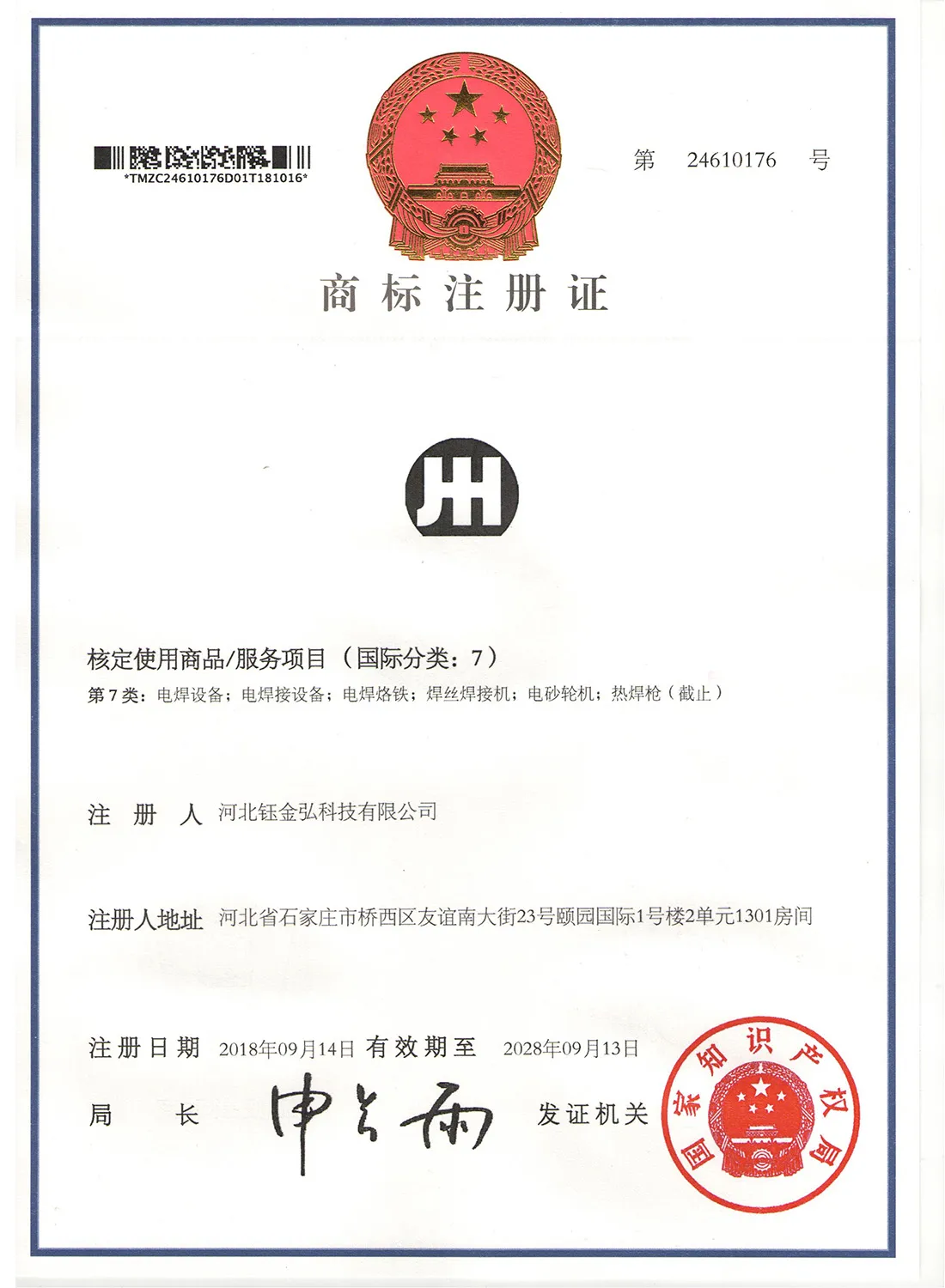

1. Quality Assurance The best manufacturers adhere to stringent quality control processes to ensure the welding wire meets industry standards. Certifications like ISO can indicate a reliable production process.

2. Variety of Products A reputable manufacturer should offer a range of ER70S wire products tailored for different applications, such as ER70S-2, ER70S-3, and ER70S-6. Each variant may exhibit different characteristics, making it essential for users to have options.

3. Customer Service Strong customer support is critical, especially for businesses that may require technical assistance or advice on selecting the right type of welding wire for specific projects.

4. Competitive Pricing Wholesale manufacturers should offer competitive pricing without compromising on quality. Bulk purchasing options can further enhance savings for welding contractors.

5. Timely Delivery Reliability in shipping and delivery schedules is crucial to maintaining workflow and ensuring that construction or manufacturing timelines are met.

Conclusion

As the demand for efficient and high-quality welding materials rises, wholesale ER70S welding wire manufacturers are essential players in the welding supply chain. These manufacturers not only provide the necessary materials but also contribute to the overall efficiency and quality of welding projects across various industries. By focusing on quality assurance, product variety, customer service, pricing, and delivery, businesses can forge successful partnerships with these manufacturers, ensuring successful outcomes in their welding endeavors.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025