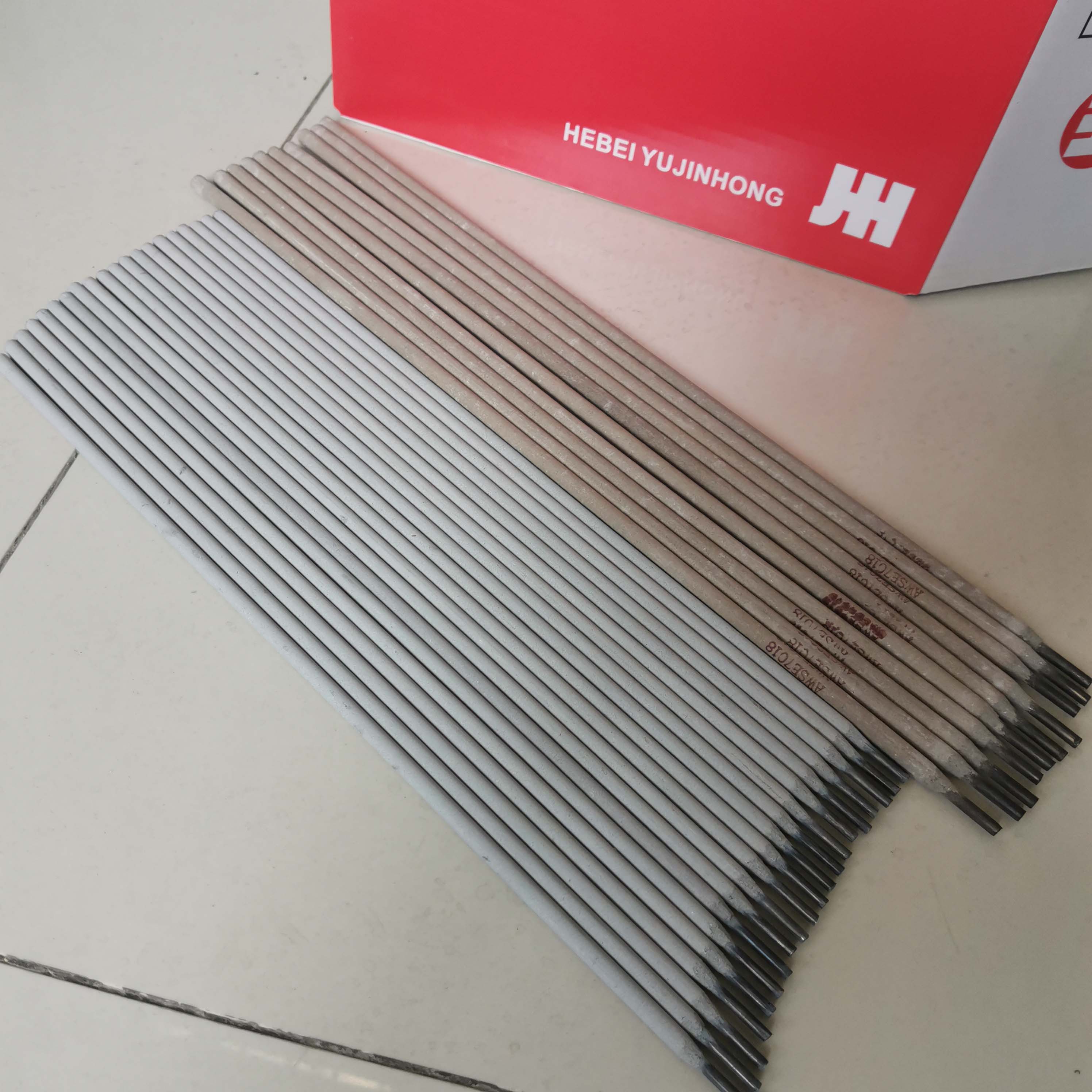

wholesale flux cored welding wire manufacturer

The Importance of Wholesale Flux-Cored Welding Wire Manufacturers

In the world of industrial manufacturing and construction, welding is an essential process that forms strong bonds between metals. Among the various welding techniques, flux-cored arc welding (FCAW) has gained significant popularity due to its numerous advantages. As industries continue to expand, the demand for quality welding materials skyrockets, leading to an increased focus on wholesale flux-cored welding wire manufacturers.

Understanding Flux-Cored Welding

Flux-cored arc welding is a semi-automatic or automatic welding process that uses a continuous hollow wire filled with flux. This flux serves several purposes it protects the molten weld pool from atmospheric contamination, assists in arc stability, and contributes to the formation of slag, which helps clean the weld. Two variations of FCAW exist the self-shielded and gas-shielded methods. Self-shielded FCAW does not require external shielding gas, making it ideal for outdoor use, while gas-shielded FCAW provides superior weld quality and is typically employed in more controlled environments.

The Role of Wholesale Manufacturers

Wholesale flux-cored welding wire manufacturers play a critical role in ensuring that businesses, from small workshops to large manufacturing plants, have access to the materials required for effective welding operations

. These manufacturers produce wires in bulk, allowing them to offer competitive prices that can significantly reduce costs for end-users.Furthermore, wholesale manufacturers often provide a variety of welding wires tailored to specific applications. For instance, different alloys and flux compositions can be formulated to meet the requirements of various welding tasks, whether it's for pipe welding in construction or sheet metal work in automotive manufacturing. In this way, manufacturers work closely with their clients to ensure that they have the right materials for their unique projects.

Quality Assurance and Standards

wholesale flux cored welding wire manufacturer

One of the primary concerns for companies using flux-cored wires is the quality of the product. Welding is a critical process, and subpar materials can lead to weak welds, which can result in structural failures. Geography, climate, and the specific materials being welded all influence the choice of welding wire, making it imperative for manufacturers to adhere to stringent quality standards.

Many manufacturers obtain certifications from relevant industry bodies, ensuring that their products meet international standards like ISO and AWS (American Welding Society). This commitment to quality not only enhances their reputation but also builds trust among their customer base. Customers can be assured that they are using reliable materials that will perform consistently under various conditions.

Sustainability in Flux-Cored Wire Production

As industries become increasingly aware of their environmental impact, many wholesale flux-cored welding wire manufacturers are adopting sustainable practices. This includes reducing waste during production, recycling scrap materials, and ensuring that the raw materials sourced are obtained responsibly.

Moreover, some manufacturers are exploring the use of environmentally friendly flux materials that can produce fewer harmful emissions while maintaining weld quality. As governments worldwide continue to implement stringent regulations regarding environmental protection, manufacturers who prioritize sustainability will likely have a competitive edge.

Conclusion

Wholesale flux-cored welding wire manufacturers play an indispensable role in the welding industry, providing essential materials that support various manufacturing processes. By offering a range of high-quality, cost-effective welding wires tailored to diverse applications, these manufacturers help businesses maintain efficiency and ensure the integrity of their welds. With a focus on quality assurance and sustainable practices, the future of wholesale flux-cored welding wire manufacturing looks promising, paving the way for innovation in welding techniques and materials. As industries grow and evolve, the importance of these manufacturers will continue to rise, making them key players in the global manufacturing landscape.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025