Wholesale Factory for Flux Core Welding Rods and Accessories

Understanding Wholesale Flux Core Welding Rod Factories

Welding is a critical process in various industries, from construction to automotive manufacturing. Among the different welding techniques, flux core arc welding (FCAW) has gained popularity due to its efficiency and versatility. A key component in this process is the welding rod, particularly those produced in wholesale flux core welding rod factories. This article delves into the significance, manufacturing process, and advantages of these specialized factories.

What is Flux Core Welding?

Flux core welding is a semi-automatic or automatic welding process that uses a continuously fed tubular wire filled with flux. The process is often preferred for its ability to weld in various positions, its minimal cleanup requirements, and the fact that it works well in outdoor environments, even in windy conditions. Flux core welding rods are essential to this process, providing the necessary filler material and shielding from atmospheric contamination.

The Role of Wholesale Flux Core Welding Rod Factories

Wholesale flux core welding rod factories focus on producing high-quality welding rods in bulk. These factories cater to a diverse clientele, including manufacturing companies, construction firms, and repair shops. By offering products in wholesale quantities, they not only provide competitive pricing but also ensure a consistent supply of essential materials for the welding industry.

Manufacturing Process

The production of flux core welding rods involves several crucial steps

1. Raw Material Selection High-quality raw materials such as mild steel, stainless steel, and alloy materials are chosen depending on the specific requirements of the welding process.

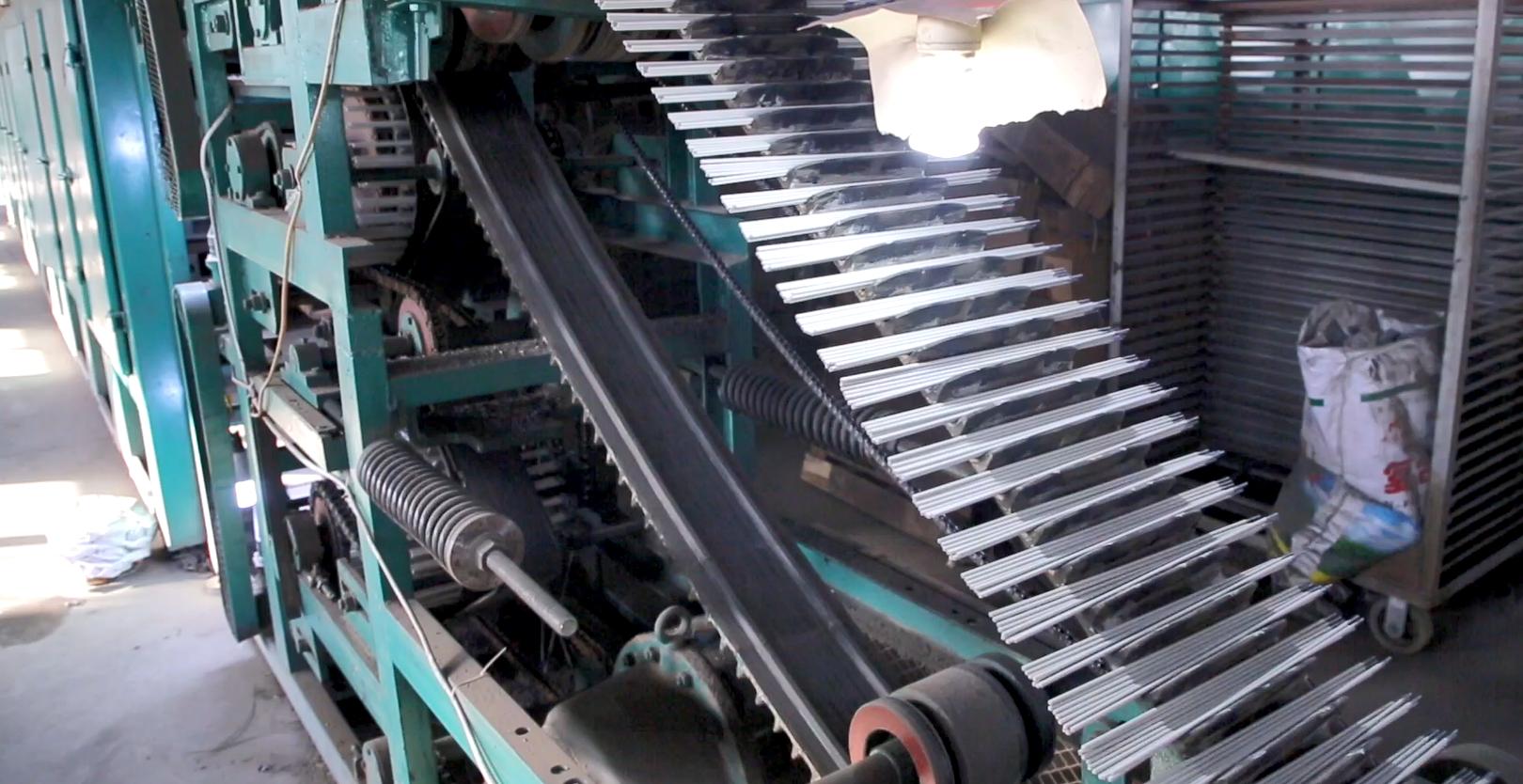

2. Tube Forming The selected materials are processed into tubular shapes. This involves rolling and welding the metal strips into tubes that will eventually become the core of the flux core welding rod.

wholesale flux core welding rod factory

3. Filling with Flux The tubes are then filled with a carefully formulated flux mixture. This flux may contain elements that enhance the welding process, such as deoxidizers, binding agents, and compounds that improve arc stability.

4. Sealing and Coiling After filling, the ends of the tubes are sealed, and the rods are coiled for easy transport and storage. Proper sealing is essential to maintain the integrity of the flux and to prevent any environmental exposure that could affect the quality of the rods.

5. Quality Control Before the welding rods are packaged for sale, they undergo rigorous quality control checks. This includes testing for strength, flexibility, and performance under various conditions. Factories often adhere to international standards, ensuring that their products meet the requirements of different industries.

Advantages of Wholesale Flux Core Welding Rod Factories

1. Cost Efficiency By purchasing welding rods from wholesale manufacturers, businesses can significantly reduce their material costs. The economies of scale achieved by these factories allow them to provide high-quality products at lower prices.

2. Wide Range of Products Wholesale flux core welding rod factories often offer a diverse selection of products. This variety enables customers to choose the right rods for their specific projects, enhancing overall efficiency.

3. Consistency in Quality Established factories adhere to strict quality control measures, ensuring that every batch of welding rods produced meets high standards. This consistency is vital for companies that rely on the performance of these materials.

4. Faster Turnaround Times Wholesale suppliers can fulfill large orders more quickly than smaller manufacturers. This ability to meet high demand promptly is a crucial factor for businesses that need to maintain production schedules.

Conclusion

Wholesale flux core welding rod factories play a pivotal role in the welding industry by supplying essential materials needed for a variety of applications. By understanding the manufacturing process and benefits of these factories, businesses can make informed decisions when it comes to sourcing their welding rods. Whether for large-scale construction projects or intricate metalwork, the right welding rod can significantly impact the quality and efficiency of the welding process, underscoring the importance of reliable wholesale suppliers in this vital industry.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025