wholesale gasless mig welding wire manufacturer

Wholesale Gasless MIG Welding Wire Manufacturer A Comprehensive Overview

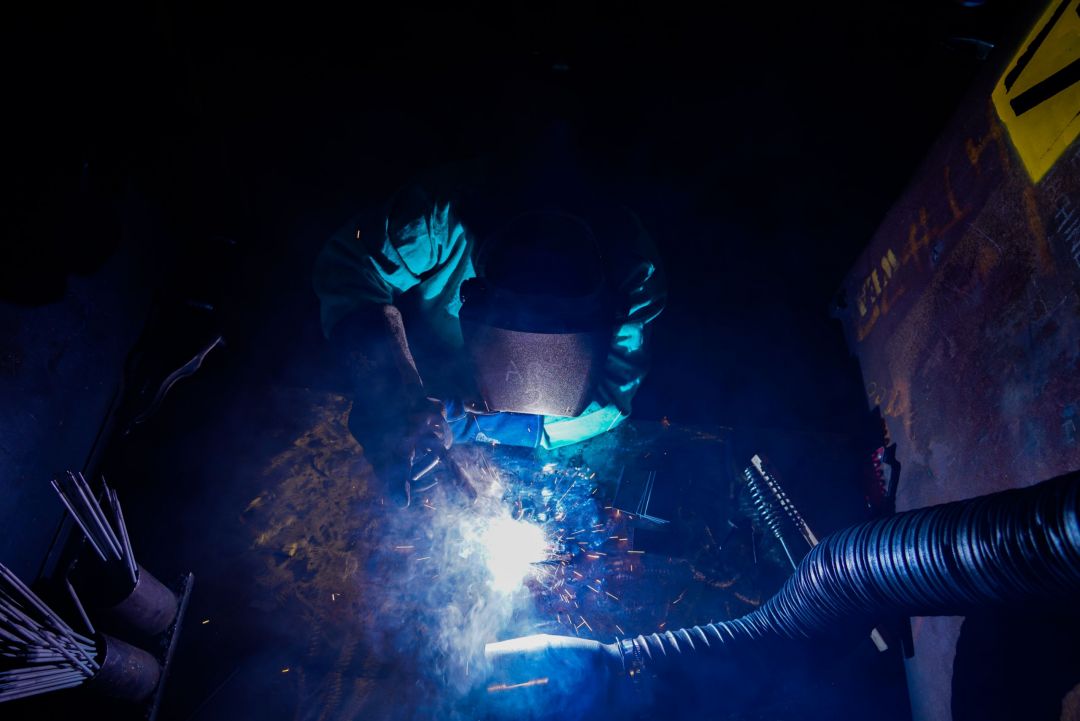

In the world of welding, particularly in the realms of Metal Inert Gas (MIG) welding, the choice of materials is pivotal in ensuring high-quality, efficient welds. Among these materials, gasless MIG welding wire stands out as a popular choice for both professional welders and DIY enthusiasts. This article explores the significance of wholesale gasless MIG welding wire manufacturers, the benefits of gasless welding, and factors to consider when sourcing this essential material.

Gasless MIG welding, also known as flux-cored welding, utilizes a wire filled with flux that creates a shielding gas as it melts. This method is particularly advantageous for outdoor applications and in windy conditions, where traditional MIG welding may pose challenges due to the dispersal of shielding gas. As a result, gasless MIG welding wire has gained popularity across various industries, including construction, automotive, and home repair.

Wholesale manufacturers of gasless MIG welding wire play a crucial role in the supply chain by offering bulk quantities at competitive prices. Sourcing from these manufacturers allows businesses and individual welders to reduce costs while ensuring a consistent supply of high-quality materials. When selecting a wholesale supplier, it’s essential to consider several key factors.

First, the quality of the welding wire is paramount. A reputable manufacturer should adhere to strict quality control standards and provide documentation, such as certifications, to assure customers of the wire's performance and safety. High-quality gasless MIG welding wire is designed to offer excellent arc stability, minimal spatter, and strong welds, which are critical for achieving satisfactory results.

wholesale gasless mig welding wire manufacturer

Second, the range of products offered by the manufacturer matters. An ideal supplier should have a diverse selection of diameters and types of gasless welding wire to cater to different applications. Whether it’s for thin sheet metal or thicker materials, having access to various options ensures that welders can select the best wire for their specific projects.

Another consideration is the manufacturer's reputation and customer service. Engaging with a supplier known for their reliability and responsiveness can make a significant difference in the purchasing experience. Look for reviews and testimonials from other customers to gauge the manufacturer’s credibility.

Additionally, logistical aspects such as shipping times and costs should be evaluated. A manufacturer that offers efficient delivery options can help minimize downtime, allowing welders to complete their projects on schedule.

In conclusion, wholesale gasless MIG welding wire manufacturers are essential partners in the welding industry, providing valuable materials that enhance the effectiveness and efficiency of welding processes. By prioritizing quality, variety, and service, welders can ensure they have the best materials at their disposal, ultimately leading to superior welds and satisfied customers.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025