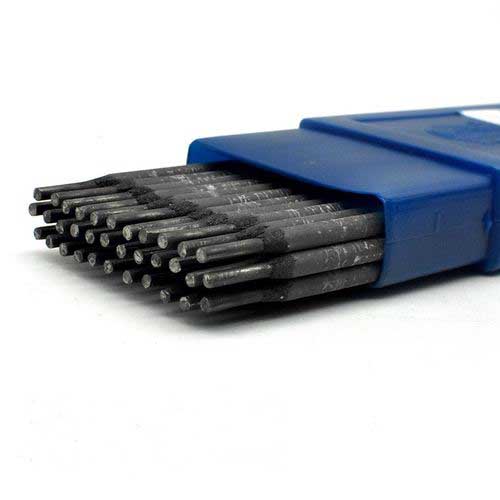

wholesale metal core welding wire suppliers

The Role of Wholesale Metal Core Welding Wire Suppliers in Modern Manufacturing

In today's manufacturing landscape, the demand for high-quality welding supplies is at an all-time high. Among these supplies, metal core welding wires have emerged as a vital component for various industrial applications. As a result, wholesale metal core welding wire suppliers play a crucial role in providing manufacturers with the materials they need to ensure efficiency, quality, and durability in their welding projects.

Understanding Metal Core Welding Wires

Metal core welding wires are a type of filler material used in the welding process, specifically designed to enhance the performance of welding operations. Unlike traditional solid wires, metal core wires consist of a metallic core surrounded by a shell of flux material, which facilitates a more efficient welding process. This innovative design leads to increased deposition rates, reduced spatter, and superior weld quality, making it a preferred choice for many applications.

The advantages of using metal core welding wire include improved productivity due to faster travel speeds, enhanced arc stability because of the flux component, and better mechanical properties of the welded joint. These features make metal core welding wires particularly favored in industries such as automotive, shipbuilding, and construction, where strength and reliability are paramount.

The Importance of Wholesale Suppliers

Wholesale metal core welding wire suppliers are essential in the supply chain for manufacturers and welders

. They serve as intermediaries between manufacturers of welding materials and end-users, providing bulk quantities of welding wires at competitive prices. By sourcing these materials in large volumes, wholesale suppliers can offer significant cost savings to their customers, allowing manufacturers to maintain their margins while ensuring they have the materials necessary for production.Additionally, wholesale suppliers typically offer a wide range of products to accommodate different welding needs. They stock various diameters and types of metal core wires, catering to specific applications and industries. This variety allows manufacturers to find the right welding materials without having to shop around for different suppliers, thus streamlining the procurement process.

wholesale metal core welding wire suppliers

Quality Control and Standards

A critical function of wholesale metal core welding wire suppliers is ensuring that the products they deliver meet industry standards and regulations. Quality control measures are imperative, as the performance of metal core welding wires directly impacts the overall quality of welds produced. Reputable suppliers often work closely with manufacturers to develop products that adhere to strict specifications, ensuring consistency and reliability with each batch.

Furthermore, many wholesale suppliers provide additional resources to assist their customers. This can include technical support, product training, and information on best practices for welding applications. By offering these services, suppliers not only reinforce the importance of quality but also help manufacturers optimize their welding processes for better results.

Trends in the Industry

The welding industry is continually evolving, driven by advancements in technology and changes in manufacturing practices. One notable trend is the increased demand for automation in welding processes. As more manufacturers adopt robotic welding systems, the need for high-quality, consistent welding materials becomes even more critical. Suppliers who can provide metal core welding wires specifically designed for automated applications will have a competitive advantage in the market.

Sustainability is another crucial trend shaping the industry. Many manufacturers are seeking eco-friendly options in their supply chains, leading suppliers to explore more sustainable sourcing and production methods. This shift towards sustainability not only benefits the environment but also aligns with the values of modern consumers who prioritize responsible manufacturing practices.

Conclusion

Wholesale metal core welding wire suppliers are integral to the success of the manufacturing sector. By providing high-quality welding materials, excellent customer service, and maintaining rigorous quality standards, these suppliers enable manufacturers to enhance their welding operations, ensuring durability and reliability in their products. As the industry continues to evolve with technological advancements and sustainability initiatives, the role of wholesale suppliers will remain vital, fostering innovation and efficiency in welding practices. The collaboration between suppliers and manufacturers promises to drive the industry forward, positioning it for a successful future.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025