Wholesale Suppliers for High-Quality MIG Flux Core Welding Wire Options

The Rise of Wholesale MIG Flux Core Wire Factories A Comprehensive Overview

In the ever-evolving landscape of welding technology, the demand for efficient and versatile welding supplies is rising sharply. Among these supplies, MIG (Metal Inert Gas) flux core wires have gained prominence, especially in wholesale markets. This article delves into the burgeoning sector of wholesale MIG flux core wire factories, exploring their significance, benefits, production processes, and the future of this industry.

Understanding MIG Flux Core Wire

MIG flux core wire is a type of welding wire that is used in a process where an electric arc is formed between a continuously fed wire electrode and the workpiece. The term flux core implies that the wire has a core filled with flux, a substance that provides shielding to the weld pool and helps in the creation of high-quality welds. The primary advantage of using flux core wire is that it can be utilized in various positions and conditions, making it ideal for both indoor and outdoor applications.

The Market for Wholesale MIG Flux Core Wire

The wholesale market for MIG flux core wire has witnessed significant growth due to an increase in construction, manufacturing, and automotive industries. As these sectors expand, the need for efficient welding solutions has never been greater. Factories specializing in the wholesale production of MIG flux core wire are striving to meet this rising demand by offering high-quality materials at competitive prices.

Wholesalers often work directly with manufacturers to source large quantities of wire. This not only allows them to benefit from economies of scale but also ensures that they can provide products that meet the diverse needs of their clients. Retailers, contractors, and commercial users benefit from these wholesale channels, as they can obtain quality materials quickly and at a reduced cost.

Benefits of Wholesale MIG Flux Core Wire Factories

1. Cost Efficiency Wholesale factories are able to produce MIG flux core wire in large volumes, reducing the production costs per unit. These savings can then be passed down to distributors and ultimately to end-users, making it more affordable for businesses that rely on welding.

2. Quality Control Many wholesale factories implement stringent quality control measures to ensure that the wire produced meets industry standards. This guarantees that customers receive a reliable product that can perform under various working conditions.

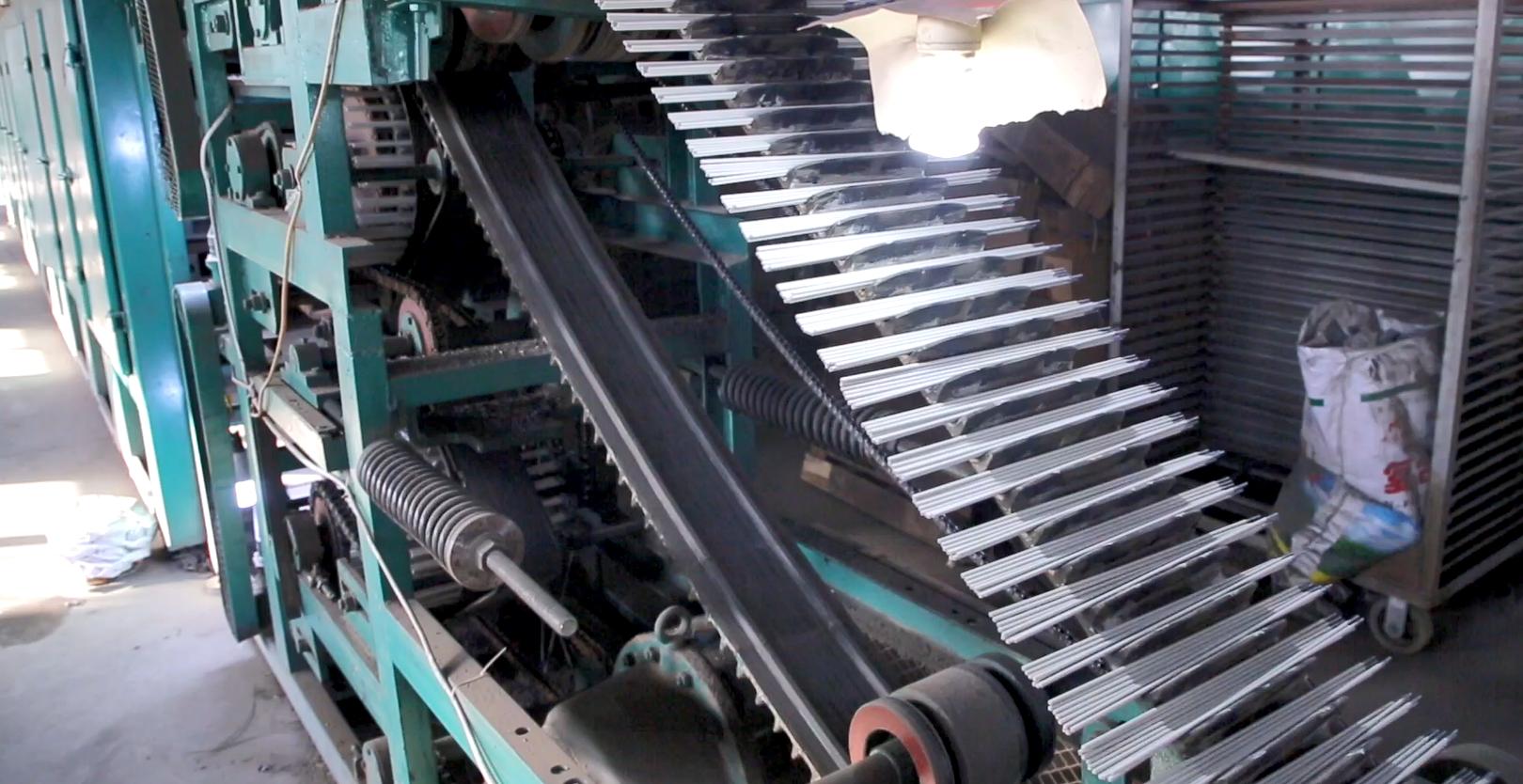

wholesale mig flux core wire factories

3. Diverse Product Range Wholesale factories often offer a wide array of flux core wires, catering to different welding applications. From low carbon steel wires to stainless steel variants, the vast selection helps businesses find the right type of wire for their specific needs.

4. Supply Chain Simplification Establishing direct relationships with wholesale factories simplifies the supply chain. Manufacturers can maintain better inventory control and reduce lead times, ensuring that customers receive their products promptly.

5. Innovative Technologies Many wholesale manufacturers are investing in research and development to enhance the quality and performance of their welding wires. Innovations in materials and production techniques can lead to improved welding properties, benefiting both small and large-scale welding operations.

Challenges Faced by Wholesale Factories

Despite their growth and success, wholesale MIG flux core wire factories face several challenges. Competition from low-cost producers, particularly those located overseas, can impact pricing and market share. Additionally, fluctuations in raw material prices can affect production costs. To mitigate these challenges, factories are increasingly focusing on quality differentiation, customer service, and developing unique wire formulations to stand out in the crowded market.

The Future of Wholesale MIG Flux Core Wire Factories

Looking ahead, the future of wholesale MIG flux core wire factories appears promising. As industries continue to grow and evolve, the demand for high-quality welding solutions will likely persist. Furthermore, advancements in automation and manufacturing technologies will enhance production capabilities, allowing factories to respond more effectively to changing market needs.

Additionally, as sustainability becomes a pressing concern globally, manufacturers are exploring eco-friendly practices and materials in their production processes. This shift may create new opportunities for wholesale factories that prioritize environmentally responsible practices.

In conclusion, wholesale MIG flux core wire factories represent a crucial component of the welding supply chain. By offering cost-effective, high-quality products, they are meeting the demands of an expanding market while paving the way for innovative advancements in welding technology. As the industry looks to the future, these factories will play an essential role in shaping the landscape of modern welding practices.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025