wholesale mig welding aluminum wire factory

Wholesale MIG Welding Aluminum Wire A Comprehensive Guide

In the world of welding, aluminum has become a favored material due to its lightweight nature and excellent corrosion resistance. One of the most effective methods of joining aluminum pieces is through Metal Inert Gas (MIG) welding, which relies on a continuous feed of a welding wire. In this context, understanding the wholesale market for MIG welding aluminum wire is crucial for manufacturers, contractors, and DIY enthusiasts alike.

Wholesale MIG welding aluminum wire suppliers cater to a growing demand for high-quality welding materials that are both cost-effective and efficient. The advantages of purchasing aluminum wire in bulk are manifold. First and foremost, it reduces costs per unit, enabling businesses and individuals to save money over time. For manufacturers who require large quantities of welding wire for production, wholesale options ensure a steady supply without the worry of fluctuating prices.

MIG welding aluminum wire comes in various diameters and compositions. The most common wire used in MIG welding for aluminum is ER4047 and ER5356. The choice of wire depends on the specific application and the properties required in the welded joint. For instance, ER4047 has a higher silicon content, making it suitable for welding thin aluminum sections, while ER5356 is more appropriate for applications that require higher strength.

wholesale mig welding aluminum wire factory

Quality is paramount when selecting wholesale aluminum wire. A reputable supplier should provide wire that meets the American Welding Society (AWS) standards to ensure optimal performance. Using subpar wire can lead to poor weld quality, increased defects, and ultimately, project failure. Therefore, buyers should prioritize purchasing from trusted manufacturers who offer certification and adherence to quality control measures.

Another critical aspect to consider is the packaging and storage of aluminum wire. Wholesale suppliers often provide spooled wire, which helps in easy handling and minimizes tangling. Additionally, proper storage of aluminum wire is essential, as exposure to moisture can lead to oxidation, affecting performance. Buyers should confirm that suppliers offer appropriate packaging solutions to protect the wire during transport and storage.

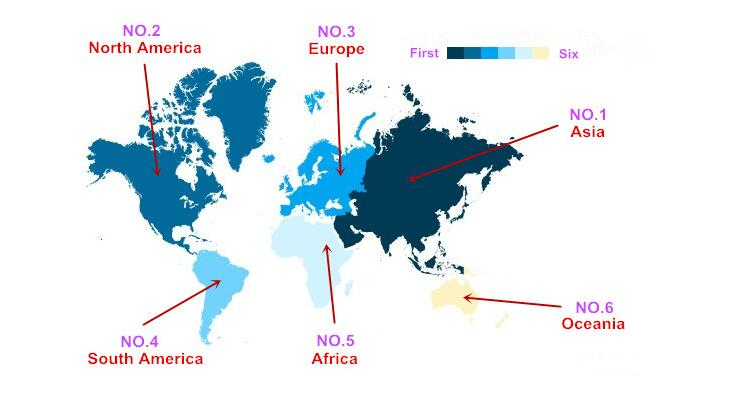

The demand for MIG welding aluminum wire is increasing, driven by sectors such as automotive, aerospace, construction, and manufacturing. As industries evolve, there is a growing need for lightweight materials that can withstand various conditions. Businesses engaged in these sectors are likely to benefit from establishing a relationship with a reliable wholesale supplier, ensuring they can access quality materials without interruption.

In conclusion, the wholesale market for MIG welding aluminum wire is a vital component for those involved in manufacturing and construction. With the multitude of suppliers available, it is essential to choose wisely, focusing not only on cost but also on quality and service. By investing in high-quality aluminum wire from reputable sources, welding professionals can enhance their efficiency, improve weld quality, and ultimately contribute significantly to their projects' success. Consider the evolving needs within the industries you serve, and take advantage of the opportunities presented by wholesale purchasing of aluminum welding wire.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025