Wholesale MIG Welding Wire for Superior Performance and Quality Solutions

The Importance of Wholesale MIG Welding Wire in the Welding Industry

MIG (Metal Inert Gas) welding, also known as Gas Metal Arc Welding (GMAW), is one of the most widely used welding processes in metal fabrication today. It is favored for its speed, versatility, and ease of use, making it an ideal choice for both novice and experienced welders. At the heart of this process is the welding wire, specifically MIG welding wire, which serves as the filler material to join two pieces of metal together. In recent years, the demand for wholesale MIG welding wire has grown significantly due to various factors affecting the welding industry.

Understanding MIG Welding Wire

MIG welding wire is typically made from various metals, such as mild steel, stainless steel, and aluminum, depending on the materials being welded. The wire is supplied on spools and is continuously fed through the welding gun, where it melts upon contact with the workpieces, creating a strong bond. The type of wire is chosen based on the specific requirements of the welding project, including the base material, desired strength, and environmental conditions.

The Rise of Wholesale Options

One of the significant trends in the welding supply industry is the increasing availability of wholesale MIG welding wire. This shift has come about due to some key factors

1. Cost-Effectiveness Purchasing MIG welding wire in bulk often provides significant savings for businesses. Wholesalers can offer better pricing structures compared to retail due to lower overhead costs and higher volume sales. This is especially beneficial for companies that require a large quantity of wire for ongoing projects.

2. Convenience For welding shops and manufacturers, sourcing wholesale MIG welding wire eliminates the need for frequent reorders and minimizes downtime. With bulk purchases, businesses can maintain a steady supply chain, ensuring they have the necessary materials to complete projects without delay.

3. Variety and Quality Wholesalers often provide a broader range of MIG welding wires compared to retail outlets. This includes different alloys, diameters, and coatings suited for various applications. Additionally, reputable wholesalers prioritize quality, ensuring that their products meet industry standards and deliver optimal performance in welding tasks.

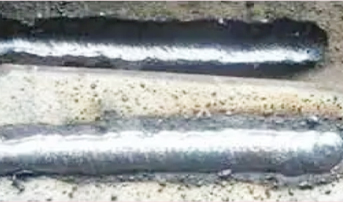

wholesale mig welding wire

Key Considerations When Choosing Wholesale MIG Welding Wire

When selecting your wholesale MIG welding wire supplier, several important factors should be taken into account

- Material Compatibility Ensure the wire you choose is compatible with the base metals you intend to weld. Different applications might require specific compositions or coatings, so it’s essential to consult technical data sheets or seek expert advice.

- Wire Diameter The diameter of the welding wire affects the welding speed and penetration. Common diameters range from 0.023 to 0.045 inches. Larger diameters are typically used for thicker materials, while smaller diameters may be preferable for thin sheets.

- Packaging and Delivery Consider the packaging options and delivery terms offered by the wholesaler. Ensure they can meet your project's scale and schedule without compromising the quality of the wire.

- Support and Expertise A good wholesaler should offer comprehensive customer support, including technical advice and assistance in selecting the right products for your particular welding applications.

Conclusion

Wholesale MIG welding wire has become a crucial component in the welding industry landscape, offering numerous benefits such as cost savings, convenience, and access to a wide range of products. As manufacturers and welding shops continue to seek efficiencies in their operations, the importance of sourcing high-quality materials cannot be overstated. By opting for wholesale MIG welding wire, businesses can ensure they maintain performance quality, reduce costs, and strengthen their overall production capabilities. As the industry evolves, organizations must stay informed about the best suppliers and the latest advancements in welding technology to remain competitive.

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025