Top Suppliers for Wholesale Stainless Steel Welding Electrodes and Accessories

Wholesale Stainless Steel Welding Electrodes Suppliers A Comprehensive Guide

In the modern industrial landscape, the demand for efficient and durable welding solutions has skyrocketed. Among the various materials used in welding, stainless steel remains a top choice due to its strength, corrosion resistance, and overall versatility. As industries evolve, so too does the necessity for high-quality welding electrodes. This is where the role of wholesale stainless steel welding electrodes suppliers becomes crucial.

The Importance of Quality Electrodes

Welding is an essential process in manufacturing, construction, and repair. The quality of the welding electrode significantly influences the strength and integrity of the welded joint. Stainless steel welding electrodes are designed for different types of applications including structural, automotive, and marine projects. Therefore, sourcing these electrodes from reputable suppliers is paramount.

Quality electrodes not only guarantee better performance but also contribute to overall operational efficiency. Reliable suppliers offer products that meet industry standards, ensuring that you receive electrodes that are tested, certified, and consistent in quality.

What to Look for in Suppliers

When searching for wholesale stainless steel welding electrodes suppliers, several factors come into play

1. Product Range It’s important to choose suppliers that provide a wide range of electrodes suitable for various welding methods such as MIG, TIG, and stick welding. Specialty electrodes for specific grades of stainless steel can also enhance your welding processes.

2. Certifications and Standards Ensure that the suppliers comply with relevant industry certifications, such as ISO 9001. This guarantees that the products adhere to stringent quality assurance processes.

3. Pricing Structure Wholesale suppliers often provide bulk purchasing options that can significantly reduce costs. Compare prices among different suppliers to find competitive rates without compromising quality.

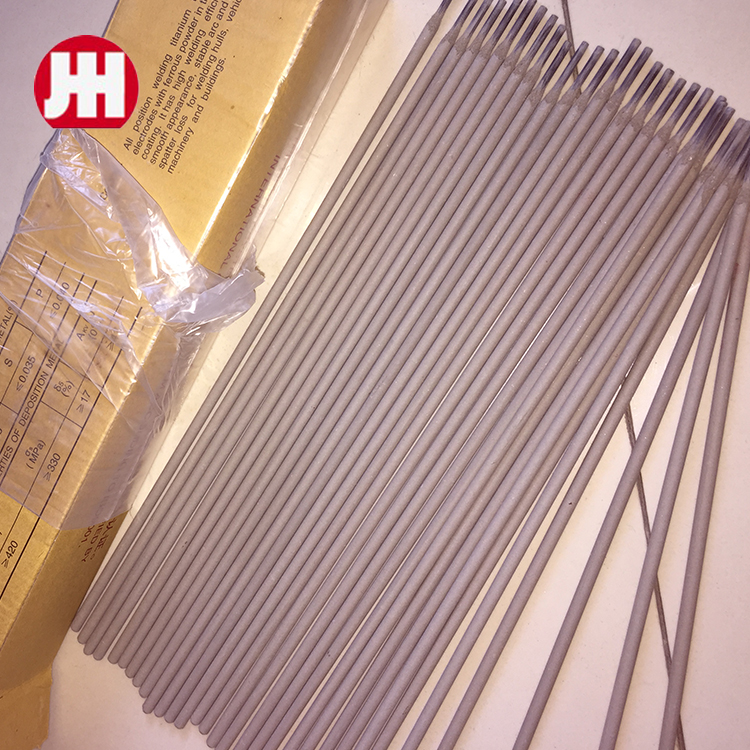

wholesale stainless welding electrodes suppliers

4. Technical Support A knowledgeable supplier will offer additional services, such as technical support and recommendations based on the specific requirements of your projects. This can be invaluable for troubleshooting and optimizing welding processes.

5. Reputation and Experience Research potential suppliers’ reputations in the market. Check customer reviews, testimonials, and case studies to gauge their reliability and service quality over time.

6. Logistics and Delivery Fast and reliable shipping is crucial in maintaining workflow efficiency. Check the supplier's delivery times and logistics capabilities to ensure they align with your project schedules.

Leading Suppliers in the Market

As the market evolves, several suppliers have established themselves as leaders in wholesale stainless steel welding electrodes. Companies like ESAB, Lincoln Electric, and Hobart are renowned for their high-quality welding products. Furthermore, many specialized suppliers focus solely on stainless steel welding electrodes, providing tailored solutions for specific customer needs.

Local suppliers can also offer advantages, such as lower shipping costs and faster delivery times. It’s beneficial to explore both national and local options to find the best fit for your requirements.

Sustainability Considerations

In today's industrial climate, sustainability is becoming increasingly important. Some suppliers offer eco-friendly welding electrodes that are manufactured using processes that minimize environmental impact. Choosing suppliers who prioritize sustainability not only aids in compliance with environmental regulations but also enhances your company's corporate responsibility profile.

Conclusion

The selection of the right wholesale stainless steel welding electrodes suppliers can significantly affect the quality and success of welding operations across various industries. By prioritizing factors such as product range, certifications, pricing, and supplier reputation, businesses can forge strong, reliable partnerships that contribute to long-term operational success. As the landscape of manufacturing and construction continues to evolve, ensuring access to high-quality materials will remain an essential component of efficient and effective work practices.

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025