Leading Manufacturer of Wholesale Steel Welding Wire Solutions for Your Needs

The Role of Wholesale Steel Welding Wire Manufacturers in the Industry

Welding is an essential process in various industries, forming the backbone of manufacturing, construction, and metal fabrication. At the heart of this process lies steel welding wire, a critical component that ensures successful joint formation between metals. As globalization expands, wholesale steel welding wire manufacturers have increasingly become pivotal players in the welding supply chain, delivering quality products to meet the ever-growing demands of the market.

Understanding Steel Welding Wire

Steel welding wire is primarily used in different welding processes, including Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW). Depending on the type of welding process, the characteristics of the welding wire vary significantly. For instance, solid welding wires are commonly utilized in GMAW, while flux-cored wires are favored for outdoor applications due to their ability to withstand windy conditions.

The performance of welding wire directly affects the quality of the welded joint. Therefore, it is crucial to select the right type of wire based on the base materials and the application involved. This is where wholesale steel welding wire manufacturers come into play, offering a vast range of options to cater to diverse industrial needs.

The Importance of Wholesale Manufacturers

Wholesale steel welding wire manufacturers are vital for maintaining a smooth supply chain. They empower businesses by providing cost-effective solutions and ensuring that high-quality materials are readily available. These manufacturers often procure raw materials in bulk, allowing them to produce welding wire at a lower cost per unit. Consequently, they can pass these savings on to their customers, making it more economical for construction and manufacturing companies to acquire the materials they need.

Furthermore, wholesale manufacturers frequently offer customization options, enabling clients to obtain welding wire tailored to specific applications. This flexibility is particularly beneficial for specialized industries, such as aerospace and automotive, that require unique material properties to meet stringent regulatory standards.

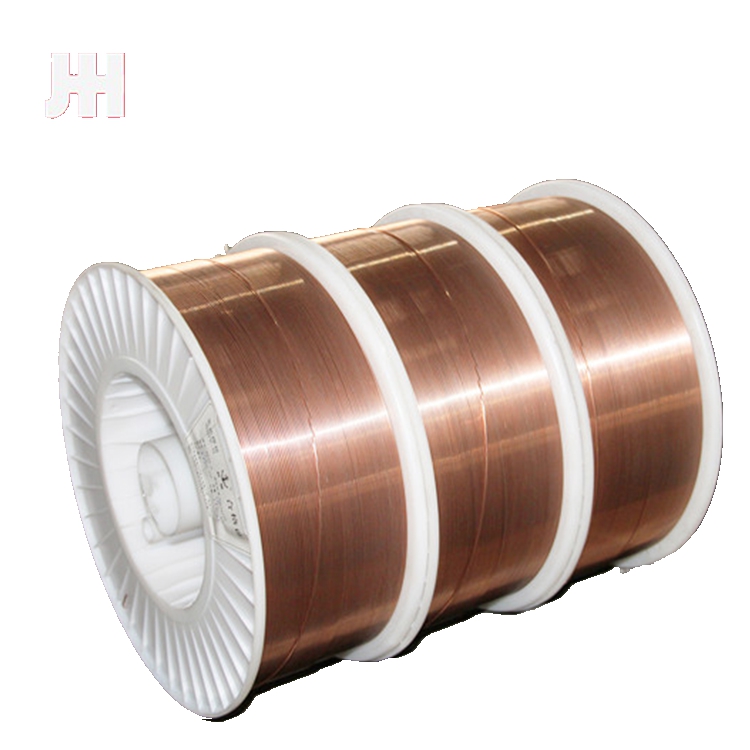

wholesale steel welding wire manufacturer

Quality Control and Compliance

In the competitive world of welding supplies, quality is paramount. Reputable wholesale steel welding wire manufacturers are committed to upholding industry standards and regulations. They implement stringent quality control measures throughout the production process, from raw material selection to the final inspection of the finished product. This ensures that the welding wire is not only compliant with international standards but also reliable and consistent in performance.

Many wholesale manufacturers also hold relevant certifications, such as ISO 9001, which reflects their commitment to quality management practices. These certifications provide customers with confidence, reassuring them that they are sourcing from manufacturers that prioritize quality and adhere to best practices in production.

The Impact of Technological Advancements

Technological advancements have significantly shaped the landscape of manufacturing, including the production of steel welding wire. Wholesale manufacturers are leveraging modern technologies, such as automation and artificial intelligence, to enhance efficiency and reduce production costs. By investing in state-of-the-art machinery, they can achieve higher precision in wire manufacturing, leading to superior end products.

Moreover, innovations in materials science have led to the development of improved welding wires with enhanced mechanical properties. Wholesale manufacturers are at the forefront of integrating these advancements into their product offerings, ensuring that their clients have access to the latest solutions in welding technology.

Conclusion

In summary, wholesale steel welding wire manufacturers play an essential role in the welding industry by supplying quality materials that meet diverse needs across various sectors. They provide cost-effective solutions, uphold stringent quality standards, and embrace technological advancements to enhance their products. As industries continue to evolve, the demand for reliable welding wire will undoubtedly rise, reinforcing the significance of wholesale manufacturers as key players in the supply chain. With their commitment to quality, innovation, and customer satisfaction, these manufacturers are well-equipped to support the growing requirements of the welding industry for years to come.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025