wholesale welding electrodos manufacturers

The Rise of Wholesale Welding Electrode Manufacturers

The welding industry is an essential pillar of modern manufacturing, construction, and repair sectors. At its core lies the need for high-quality welding electrodes, which play a critical role in ensuring strong and durable welds. As global demand for welding services continues to rise, so does the need for wholesale welding electrode manufacturers. This article explores the growing significance of these manufacturers in the welding supply chain, highlighting their impact on quality, cost, and accessibility.

Understanding Welding Electrodes

Welding electrodes are crucial components in the welding process, serving as the filler material that bonds two metals together under extreme heat. They come in various types, including consumable and non-consumable electrodes, each designed for specific welding techniques such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding. The choice of electrode directly affects the integrity of the weld and, consequently, the safety and longevity of the finished product.

The Role of Wholesale Manufacturers

Wholesale welding electrode manufacturers play a pivotal role in the industry by supplying large quantities of electrodes to retailers, distributors, and directly to end-users. They are essential for maintaining a steady flow of products, ensuring that welding professionals have access to the materials they need without excessive delays or inflated prices.

One of the primary advantages of purchasing welding electrodes from wholesalers is cost-effectiveness. By buying in bulk, businesses can reduce their overall expenses, allowing them to invest more in their projects or services. Furthermore, with competitive pricing strategies, wholesale manufacturers can offer high-quality products at rates that are often lower than retail prices, fostering a more accessible welding market.

Quality Assurance and Standards

wholesale welding electrodos manufacturers

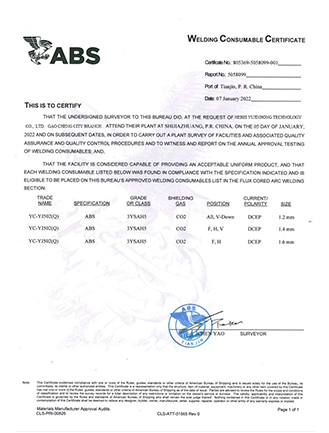

Another critical aspect of wholesale welding electrode manufacturers is their commitment to quality assurance. Many manufacturers adhere to stringent international standards, ensuring that their products meet the requirements laid out by organizations such as the American Welding Society (AWS) and the International Organization for Standardization (ISO). This focus on quality is essential in an industry where the integrity of the weld can mean the difference between safety and disaster.

Wholesale manufacturers often invest in advanced technologies and quality control measures, leading to consistent production of high-performing electrodes. They conduct rigorous testing to assess the mechanical properties, electrical conductivity, and overall performance of their products. Consequently, buyers can trust that the welding electrodes they acquire will perform reliably in various applications.

The Future of Wholesale Welding Electrodes

As the world moves towards industrial automation and digitalization, the welding industry is also evolving. The emergence of Industry 4.0 technologies is shaping how manufacturers operate, manage supply chains, and interact with customers. Wholesale welding electrode manufacturers are beginning to embrace these innovations, adopting smarter inventory management systems and exploring e-commerce platforms to enhance their reach.

Additionally, with an increasing focus on sustainability, manufacturers are exploring eco-friendly materials and production methods. As regulatory pressures grow, companies that can adapt to these changes will be better positioned to thrive in a competitive market.

Conclusion

The role of wholesale welding electrode manufacturers is vital in ensuring that the welding industry operates smoothly and efficiently. By providing access to high-quality materials at competitive prices, they contribute significantly to the success of numerous sectors. As the industry evolves, these manufacturers will continue to influence the standards of quality, affordability, and sustainability, shaping the future of welding as we know it.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025