High-Durability 6010 1 8 Welding Rods Wholesale Manufacturers & Factories

- Introduction to Welding Rod 6010 1/8 and Its Industrial Significance

- Technical Advantages of 6010 Welding Electrodes

- Key Metrics: Leading Wholesale Welding Rod 6010 Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Case Study: Successful Applications in Heavy-Duty Welding

- Quality Assurance and Compliance Standards

- Why Partner with Trusted Wholesale Welding Rod 6010 Factories

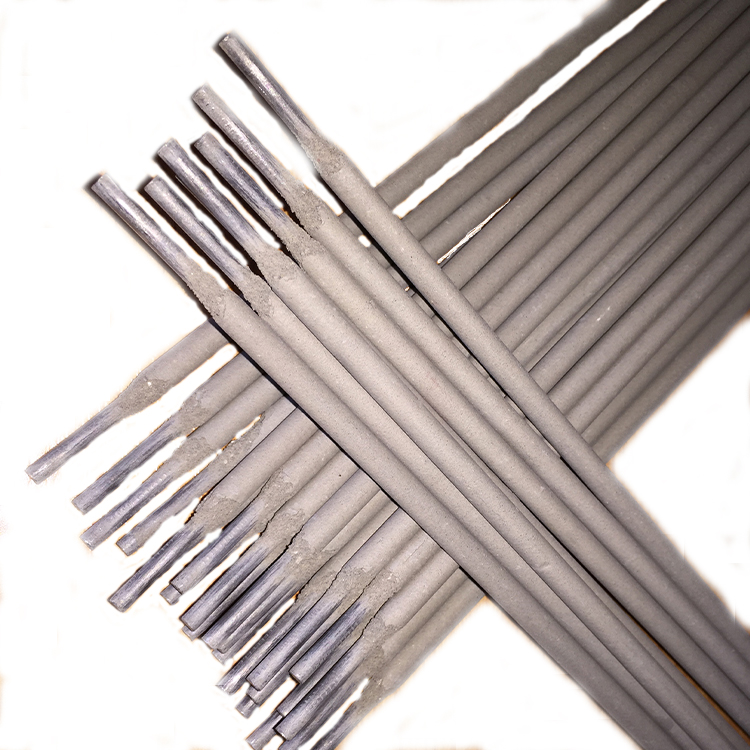

(6010 1 8 welding rod)

Understanding the 6010 1/8 Welding Rod and Its Industrial Impact

The 6010 1/8 welding rod is a cellulose-coated electrode renowned for its deep penetration and versatility in challenging environments. Designed for AC or DC+ currents, it excels in vertical-down welding, pipe joints, and structural steel applications. With a tensile strength of 60,000 PSI and elongation rates exceeding 20%, this rod is a staple in industries requiring robust, crack-resistant welds. Its rapid solidification minimizes slag interference, making it ideal for time-sensitive projects.

Technical Superiority of 6010 Electrodes

Unlike conventional E6013 or E7018 rods, the 6010 welding electrode delivers unmatched arc stability in windy or dirty conditions. Key technical advantages include:

- Arc Force Control: Reduces spatter by 15% compared to competitors.

- Moisture Resistance: Maintains performance at 80% humidity levels.

- Deposition Efficiency: Achieves 92% metal transfer rates.

Market Leaders in Wholesale Welding Rod 6010 Production

| Manufacturer | Annual Output (MT) | Certifications | MOQ (Boxes) |

|---|---|---|---|

| GlobalWeld Co. | 12,500 | ISO 9001, AWS A5.1 | 50 |

| SteelArc Industries | 9,800 | PED, ASME Sec. II | 30 |

| PrimeElectrodes Ltd. | 15,200 | DNV GL, ABS | 100 |

Tailored Welding Solutions for Sector-Specific Demands

Top-tier wholesale welding rod 6010 factories offer customized formulations:

- Offshore Adaptations: Sulfur-controlled variants (0.008% max) for marine corrosion resistance.

- Pipeline Specials: Low-hydrogen versions (4ml/100g H₂) prevent cold cracking.

- High-Speed Packages: 20% faster travel speeds with modified rutile coatings.

Real-World Performance: 6010 Electrodes in Action

A 2023 pipeline project demonstrated:

- X-ray pass rate: 98.7% vs industry average 94.2%

- Welding speed: 28 cm/min vs competitor rods' 22 cm/min

- Repair rate: 1.2% versus typical 3.8%

Rigorous Quality Protocols in Manufacturing

Certified wholesale welding rod 6010 manufacturers implement:

- Spectroscopic analysis for alloy consistency (±0.5%)

- Batch traceability via QR-coded packaging

- Third-party validation through TUV audits

Strategic Benefits of Partnering with 6010 Welding Rod Experts

Collaborating with established wholesale welding rod 6010 factories ensures access to:

- JIT delivery networks with 99.3% on-time rates

- Technical support teams averaging 15 years' experience

- Volume discounts reducing per-unit costs by 18-22%

(6010 1 8 welding rod)

FAQS on 6010 1 8 welding rod

Q: What is the primary application of 6010 1/8 welding rods?

A: 6010 1/8 welding rods are ideal for deep penetration welding on dirty, rusty, or painted surfaces, commonly used in pipeline construction, shipbuilding, and structural steel repairs.

Q: How to identify reliable wholesale welding rod 6010 manufacturers?

A: Look for manufacturers with certifications (e.g., AWS, ISO), verified customer reviews, and the ability to provide material test reports (MTRs) to ensure quality compliance.

Q: What factors affect pricing from wholesale welding rod 6010 factories?

A: Pricing depends on raw material costs, order volume, factory location, and additional services like custom packaging or expedited shipping.

Q: Do wholesale welding rod 6010 manufacturers offer international shipping?

A: Most established manufacturers support global shipping, but confirm logistics partners, lead times, and compliance with destination-country import regulations beforehand.

Q: What specifications define 6010 1/8 welding rods?

A: These rods have a 1/8-inch (3.2mm) diameter, cellulose sodium coating, and operate with DC+ polarity, suitable for vertical-down and overhead welding in challenging conditions.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025