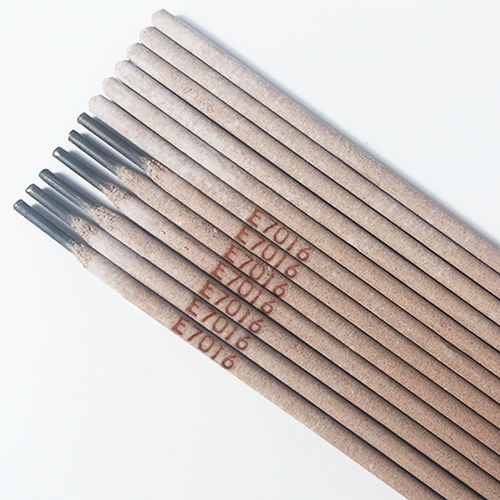

7016 Welding Rod: Low Hydrogen, High Ductility Steel Welding

Introduction to Advanced Welding Electrodes and Industry Trends

In the demanding landscape of modern industrial fabrication and repair, selecting the optimal welding consumable is paramount for ensuring structural integrity, operational longevity, and cost-efficiency. The 7016 welding rod, specifically conforming to AWS A5.1 E7016 standards, represents a critical solution for high-integrity welding applications involving carbon and certain low-alloy steels. This advanced electrode is engineered to deliver superior mechanical properties, particularly in environments requiring excellent crack resistance and toughness at sub-zero temperatures.

Current industry trends emphasize enhanced material performance, sustainability, and automated welding processes. The demand for consumables that minimize rework, reduce energy consumption, and provide consistent, high-quality welds is escalating across sectors such as petrochemical, power generation, shipbuilding, and heavy machinery manufacturing. The 7016 welding rod addresses these imperatives by offering a low-hydrogen solution that mitigates hydrogen-induced cracking, a common and costly issue in critical fabrications. Furthermore, its versatility allows for all-position welding, facilitating complex joint configurations and improving overall productivity in dynamic project environments. This comprehensive overview delves into the technical prowess, application versatility, and strategic advantages of this essential welding electrode.

Technical Specifications and Performance Profile

The AWS A5.1 E7016 Carbon Steel Welding Electrode is distinguished by its unique flux composition, which is typically of the basic or low-hydrogen type. This characteristic is crucial for applications where resistance to hydrogen cracking is critical. The 'E' prefix signifies an electrode, '70' indicates a minimum tensile strength of 70,000 psi, '1' denotes all-position welding capability, and '6' specifies the low-hydrogen potassium iron powder coating. This combination ensures robust weld integrity and exceptional mechanical properties.

Key Product Specifications: AWS A5.1 E7016 Carbon Steel Welding Electrode

| Parameter | Specification/Value |

|---|---|

| AWS Standard | A5.1 E7016 |

| Type of Coating | Low Hydrogen, Basic |

| Welding Positions | All positions (F, H, V-up, OH) |

| Typical Tensile Strength | ≥ 480 MPa (70,000 psi) |

| Typical Yield Strength | ≥ 390 MPa (57,000 psi) |

| Elongation | ≥ 22% |

| Impact Toughness (Charpy V-notch) | ≥ 27 J at -30°C (-22°F) |

| Recommended Polarity | DC+ (DCEP) |

| Re-baking Requirements | 300-350°C for 1-2 hours (if exposed to atmosphere) |

The precisely formulated low-hydrogen coating of the welding electrode 7016 ensures excellent arc stability and minimal spatter, contributing to cleaner welds and reduced post-weld cleaning. This feature, combined with its robust mechanical properties, makes the welding rod 7016 an ideal choice for critical structural applications where weld integrity cannot be compromised.

Manufacturing Process Flow of the 7016 Welding Rod

The production of a high-quality 7016 welding rod involves a meticulous multi-stage process designed to ensure consistent performance and adherence to stringent international standards such as ISO and ANSI. The process begins with carefully selected raw materials, focusing on purity and precise chemical composition.

Detailed Process Steps:

- Core Wire Production: High-grade carbon steel wire rods are drawn to precise diameters. This ensures consistent electrical conductivity and mechanical properties. Materials are typically low-carbon steel, carefully controlled for elements like Manganese and Silicon.

- Flux Material Preparation: The complex flux composition, vital for the electrode's performance, is prepared by blending various minerals and chemicals (e.g., calcium carbonate, rutile, cellulose, ferrosilicon, ferromanganese, potassium compounds). These components are pulverized to fine powders and thoroughly mixed.

- Extrusion Coating: The prepared core wire is fed through an extrusion die, where the flux mixture is uniformly applied around the wire under high pressure. This process is critical for achieving consistent coating thickness and concentricity, which directly impact arc stability and weld metal deposition.

- Baking and Drying: After extrusion, the green electrodes undergo a controlled baking process in specialized ovens. This step removes moisture, prevents hydrogen pick-up, and cures the flux coating, enhancing its mechanical strength and electrical insulating properties. Typical temperatures range from 300°C to 450°C.

- Tip Cleaning and Stamping: The ends of the electrodes are cleaned to ensure proper electrical contact, and the AWS classification (e.g., E7016) is stamped for identification and traceability.

- Quality Control and Testing: Throughout the process, rigorous quality checks are performed. This includes visual inspection, dimensional checks, chemical analysis of weld metal, mechanical property tests (tensile strength, yield strength, impact toughness via Charpy V-notch), and hydrogen content analysis. Adherence to ISO 2560 and ANSI/AWS A5.1 standards is strictly maintained.

- Packaging: Finished electrodes are hermetically sealed in moisture-proof packaging to protect the low-hydrogen coating from atmospheric moisture, ensuring their long service life and performance integrity.

The meticulous control at each stage ensures that the final 7016 welding rod exhibits superior arc characteristics, excellent slag detachability, and weld deposits with minimal hydrogen content, crucial for preventing cold cracking in high-stress applications.

Application Scenarios and Technical Advantages

The intrinsic properties of the AWS A5.1 E7016 electrode make it indispensable across a multitude of industries where weld quality and reliability are non-negotiable. Its low-hydrogen nature is particularly advantageous in scenarios demanding high resistance to cracking.

Target Industries and Applications:

- Petrochemical and Oil & Gas: For pipelines, pressure vessels, and storage tanks where critical components operate under high pressure and corrosive conditions. The welding electrode 7016 ensures robust joints capable of withstanding extreme stresses.

- Power Generation: Used in fabricating and repairing components for power plants, including boilers, turbines, and structural frameworks, where high-temperature and high-pressure resistance is vital.

- Shipbuilding: For hull structures, bulkheads, and other maritime components requiring strong, durable welds that resist the harsh marine environment.

- Heavy Machinery and Construction: In the manufacture and repair of earthmoving equipment, cranes, bridges, and structural steel, where impact strength and fatigue resistance are paramount.

- Water Supply & Drainage Systems: For critical piping and infrastructure components that demand long-term corrosion resistance and leak-proof integrity.

Demonstrated Advantages in Typical Scenarios:

- Superior Corrosion Resistance: The weld metal deposited by a 7016 welding rod often exhibits enhanced resistance to various forms of corrosion, extending the service life of fabricated components in aggressive chemical or atmospheric conditions. This is particularly beneficial in industries dealing with chemicals or saline environments.

- Energy Saving: Its stable arc and efficient metal transfer characteristics contribute to less spatter and deeper penetration, reducing the need for excessive grinding and re-welding, thus optimizing energy consumption in the overall welding process. High deposition efficiency also means less material waste.

- High Toughness at Low Temperatures: The E7016 classification guarantees excellent impact properties down to -30°C, making it ideal for applications in cold climates or cryogenic processes where brittle fracture is a concern. This is a critical advantage over conventional high-hydrogen electrodes.

- Reduced Hydrogen Embrittlement: As a low-hydrogen electrode, it significantly minimizes the risk of hydrogen-induced cracking, a critical factor for welding higher strength steels or thicker sections. This ensures structural integrity and reduces costly failures.

Vendor Comparison and Customized Solutions

Choosing the right supplier for 7016 welding rod is as critical as selecting the correct electrode itself. B2B decision-makers must evaluate vendors based on product consistency, technical support, supply chain reliability, and customization capabilities. A thorough vendor comparison goes beyond mere price points, focusing on the total value proposition.

Key Vendor Evaluation Criteria:

| Criterion | Description & Impact |

|---|---|

| Product Quality & Consistency | Ensures predictable weld performance, reduces defects, and minimizes rework. Look for ISO 9001 certification and stringent internal QC. |

| Technical Expertise & Support | Ability to provide detailed technical data, troubleshooting, and application guidance, crucial for complex projects. |

| Supply Chain Reliability | Consistent availability and on-time delivery to prevent project delays and maintain operational continuity. |

| Customization Capabilities | Flexibility to offer specific diameters, packaging, or even slightly modified formulations for unique project requirements. |

| Certifications & Compliance | Adherence to international standards (AWS, ISO, CE) and region-specific certifications (e.g., Lloyds Register, DNV, ABS). |

Tailored Solutions for Unique Project Demands:

Reputable manufacturers often provide customized solutions beyond standard offerings. This might include:

- Specific Diameters and Lengths: While standard sizes are common, certain automated or specialized welding processes may benefit from non-standard dimensions.

- Advanced Packaging Options: Enhanced moisture-proof packaging for extreme environments or long-term storage, ensuring the low-hydrogen property is preserved.

- Proprietary Certifications: Compliance with additional client-specific testing or third-party certifications required for highly regulated industries.

- Technical Consultation: Dedicated engineering support to optimize welding procedures, troubleshoot issues, and achieve specific metallurgical outcomes using the welding rod 7016.

Application Case Studies and Customer Feedback

Real-world application demonstrates the tangible benefits of using high-quality E7016 electrodes. Our commitment to delivering superior welding consumables is reflected in successful project outcomes and positive client testimonials.

Case Study 1: High-Pressure Pipeline Fabrication

A major energy infrastructure client faced challenges with hydrogen cracking and inconsistent mechanical properties when welding critical sections of a high-pressure gas pipeline in a sub-arctic region. Traditional electrodes were leading to high rejection rates and significant delays. By transitioning to a premium 7016 welding rod, specifically tailored for low-temperature impact toughness, the client achieved:

- 98% Reduction in Repair Rates: Dramatically lowering project costs and accelerating completion.

- Enhanced Weld Integrity: All welds passed rigorous non-destructive testing (NDT), including ultrasonic and radiographic examinations.

- Improved On-site Productivity: Welders reported superior arc control and slag detachability, contributing to faster work cycles.

This project underscored the importance of reliable low-hydrogen electrodes for critical infrastructure in challenging environments.

Case Study 2: Offshore Platform Maintenance

An offshore maintenance contractor required a robust welding solution for structural repairs on aging platforms, often conducted in less-than-ideal conditions. The need for exceptional all-position performance and corrosion resistance was paramount. Our high-performance welding rod 7016 was selected for its proven reliability:

- Optimized All-Position Welding: Facilitated complex overhead and vertical-up welds, critical for intricate offshore structures.

- Extended Service Life: Weld deposits exhibited enhanced resistance to saltwater corrosion and fatigue, extending the lifespan of repaired components.

- Consistency in Challenging Environments: Welders could maintain consistent quality even with variable atmospheric conditions typical of offshore operations.

Client Testimonial:

"For years, we've relied on these E7016 electrodes for our most demanding pressure vessel projects. The consistency in quality, coupled with excellent technical support, has been a game-changer. Our inspection rates are down, and our project timelines are more predictable. The team's understanding of our specific needs, especially regarding low-temperature applications, has been invaluable."

Authoritativeness, Trustworthiness, and Support

Our commitment to quality and customer satisfaction is built on a foundation of rigorous standards, transparent processes, and unwavering support. We understand that in B2B environments, trust is earned through consistent performance and reliable service.

Certifications and Compliance:

- ISO 9001:2015 Certified: Demonstrates our commitment to a robust quality management system, ensuring consistent product and service delivery.

- AWS A5.1 Compliant: All our E7016 electrodes strictly adhere to the American Welding Society's stringent specifications, guaranteeing performance.

- CE and PED Markings: Products meet European safety, health, and environmental protection requirements for pressure equipment.

- Third-Party Approvals: Approved by leading classification societies such as Lloyd's Register, DNV, Bureau Veritas, and ABS, affirming their suitability for critical applications in marine and offshore sectors.

Lead Time and Fulfillment:

We maintain optimized inventory levels and streamlined logistics to ensure efficient order fulfillment. Standard lead times for common diameters of welding electrode 7016 typically range from 5-10 business days for domestic orders, with international shipments varying based on destination and customs. For large volume or customized orders, specific timelines are provided and actively managed in consultation with the client to meet project deadlines.

Warranty and After-Sales Support:

- Product Warranty: All welding electrodes are backed by a comprehensive warranty covering manufacturing defects and ensuring compliance with stated specifications under proper storage and usage conditions.

- Technical Assistance: Our team of experienced welding engineers provides prompt technical support, offering guidance on welding parameters, troubleshooting, and application best practices. Support is available via phone, email, and on-site visits for complex issues.

- Customer Service: Dedicated account managers ensure a seamless ordering process and proactive communication throughout the supply chain, from initial inquiry to post-delivery feedback.

Frequently Asked Questions (FAQ) about the E7016 Electrode

Q1: What is the primary advantage of using a low-hydrogen 7016 welding rod?

A1: The primary advantage is its low-hydrogen content, which significantly reduces the risk of hydrogen-induced cracking (HIC), also known as cold cracking. This is crucial for welding high-strength steels, thick sections, or in situations where preheating and interpass temperature control might be challenging. It ensures higher integrity and reliability of the weldment.

Q2: What are the typical re-baking requirements for E7016 electrodes?

A2: If E7016 electrodes have been exposed to the atmosphere for an extended period (typically more than 4 hours, depending on humidity), they should be re-baked to remove absorbed moisture. The general recommendation is to re-bake at 300-350°C (572-662°F) for 1-2 hours. Always refer to the manufacturer's specific instructions for optimal results and to maintain the low-hydrogen properties.

Q3: Can the welding rod 7016 be used with AC current?

A3: While E7016 is primarily designed for DC+ (DCEP - Direct Current Electrode Positive) for optimal performance, some variations or specific formulations may allow for limited AC use. However, for critical applications and to achieve the best arc stability, penetration, and mechanical properties, DC+ is strongly recommended. Always consult the product's technical data sheet.

Q4: In which industries is the welding electrode 7016 most commonly utilized?

A4: Due to its robust mechanical properties, excellent toughness, and low-hydrogen characteristics, the E7016 electrode is widely used in industries such as petrochemical, power generation, shipbuilding, heavy construction, and pressure vessel fabrication. It's ideal for applications where weld integrity, strength, and resistance to environmental stressors are paramount.

Q5: How does proper storage affect the performance of E7016 electrodes?

A5: Proper storage is critical to maintain the low-hydrogen properties of E7016 electrodes. They should be stored in hermetically sealed container111s or in a dry, heated oven (holding oven) at temperatures typically between 100-150°C (212-302°F) once opened. Exposure to moisture will degrade the flux coating, increase hydrogen content, and compromise weld quality, leading to potential defects.

Conclusion: The Indispensable Role of the E7016 Welding Rod

The AWS A5.1 E7016 carbon steel welding electrode stands as a cornerstone in critical welding applications across demanding industrial sectors. Its advanced metallurgical properties, characterized by low-hydrogen content, exceptional toughness, and all-position welding capability, ensure superior weld integrity and long-term performance. By mitigating the risks of hydrogen-induced cracking and offering consistent mechanical strength, the 7016 welding rod empowers engineers and fabricators to achieve the highest standards of quality and safety.

Partnering with a reputable manufacturer that upholds stringent quality control, provides comprehensive technical support, and offers flexible customization options is crucial for maximizing the benefits of this indispensable consumable. As industries continue to evolve with greater demands for reliability and efficiency, the E7016 electrode remains a testament to precision engineering in welding technology, driving progress in infrastructure, energy, and manufacturing worldwide.

References

- American Welding Society. (2012). AWS A5.1/A5.1M:2012, Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding. AWS.

- ASTM International. (2018). ASTM E23, Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM.

- ISO (International Organization for Standardization). (2017). ISO 2560:2017, Welding consumables - Covered electrodes for manual metal arc welding of non-alloy and fine grain steels - Classification. ISO.

- The Welding Institute (TWI). (n.d.). Hydrogen-Induced Cracking. TWI Ltd.

- DNV GL. (2020). DNV GL Rules for Classification - Ships, Part 2 Ch. 4, Welding. DNV GL.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025