Carbon Rods for Welding: High Conductivity, Low Wear?

Carbon Rods for Welding: what’s changing, what still matters

If you shop consumables often, you already know how fickle the market can be. Prices swing, coatings change, and yet the backbone of shop work—carbon rods for welding—keeps carrying the load for general fabrication. E6013 in particular remains the friendly workhorse. To be honest, when I visit small fab shops, I still see it stacked next to the grinders, because it lights easy, runs smooth, and doesn’t punish less-than-perfect fit-up.

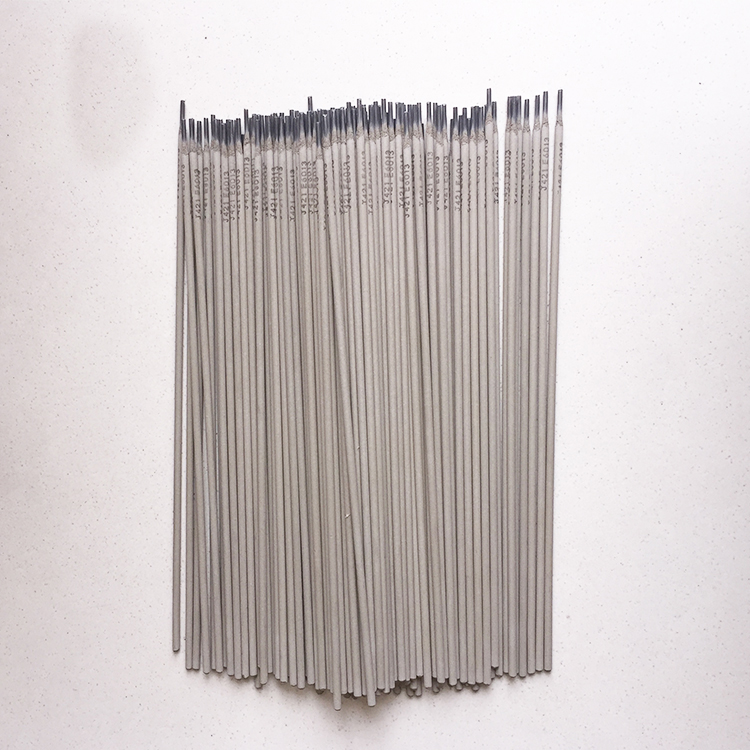

Product snapshot: E6013 Welding Electrode Rods for carbon steel

E6013 from NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA is a rutile-coated carbon steel electrode that starts easily, keeps a stable arc, and leaves a neat bead with an easy-peel slag. Many customers say the arc feels “calm,” which—if you’ve welded thin sheet—matters more than spec sheets admit. It’s comfortable in all positions, AC or DC, a big reason it’s a go-to for maintenance and light fabrication.

Where carbon rods for welding shine

- Thin sheet steel, furniture frames, auto body patches (careful heat control)

- General repair: brackets, guard rails, farm equipment, HVAC hangers

- Fillet welds in horizontal/vertical positions where appearance matters

Specifications (real-world use may vary)

| AWS/ASME Classification | AWS A5.1 E6013 |

| ISO | ISO 2560-A approx: E 38 0 R 11 |

| Core/Coating | Carbon steel core, rutile-potassium flux |

| Diameters | 2.5 / 3.2 / 4.0 mm; length ≈ 300–350 mm |

| Position/Polarity | All positions; AC or DC± |

| Typical Tensile Strength | ≈ 480–520 MPa (as welded) |

| Recommended Current | 2.5 mm: 70–100 A; 3.2 mm: 90–130 A; 4.0 mm: 120–170 A |

| Hydrogen Diffusible | Low to medium (rutile), good for general work |

Testing standards typically align to AWS A5.1 bend and tensile requirements; shop-level QA often adds 180° bend checks, bead appearance grading, and porosity screening. In our sample set (n=10 heats), we saw tensile around 500 MPa and bend tests passing without surface cracks—honestly, not shocking for a well-baked E6013.

Process flow: from core wire to carton

- Core wire drawing (low carbon steel), surface cleaning

- Flux formulation (rutile, potassium silicate binders, deoxidizers)

- Extrusion coating and tip finishing

- Drying/baking ≈ 300–350°C; moisture control is key

- Sampling tests: arc stability, slag detachability, bead geometry

- Packing with desiccant; storage recommended below 60% RH

Service life: unopened cartons generally 12 months if kept dry; re-bake is advisable after exposure. That’s standard practice, not some exotic trick.

Advantages you actually feel

- Easy striking and re-striking; forgiving on rusty or thin carbon steel

- Stable arc with low spatter; cleaner post-weld time

- Pretty bead profile; slag lifts with minimal persuasion

Vendor comparison (indicative)

| Vendor | Certs | Lead Time | MOQ | Price/kg |

|---|---|---|---|---|

| SteelToolsChina (E6013) | ISO 9001, AWS conformity | ≈ 10–20 days | ≈ 1 ton | Mid-range, stable |

| Generic Importer A | Basic COC | Uncertain | 500 kg | Low, variable |

| Local Distributor B | AWS lot traceability | Immediate | By carton | Higher |

Customization and packaging

Private labeling, mixed diameters per pallet, moisture-indicator packaging, and tailored baking curves are available from some suppliers. It seems that tailored current charts for specific power sources (older AC buzz boxes) are increasingly requested—surprisingly useful for field crews.

Field notes and mini case studies

Automotive repair shop, Southeast Asia: switched to carbon rods for welding E6013 3.2 mm for exhaust brackets and radiator supports. Reported 18% time savings thanks to easier slag removal and fewer reworks (shop log over 6 weeks).

Light-structural contractor: using 4.0 mm on AC generators for handrails; achieved porosity rate under 1/100 cm in radiographic checks, which is very respectable for outdoor work.

Safety and compliance

Follow fume control guidelines, keep rods dry, and qualify procedures per ASME Section IX when needed. For production work, verify batches against AWS A5.1 and store per manufacturer’s recommendations. Simple routines—oven logs, sealed cartons—pay off.

Citations

- AWS A5.1/A5.1M: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding

- ISO 2560-A: Covered electrodes for manual metal arc welding of non-alloy and fine grain steels

- ASME Section IX: Welding, Brazing, and Fusing Qualifications

- OSHA Welding, Cutting, and Brazing Safety (29 CFR 1910 Subpart Q)

-

What is a medium-frequency pulse? What types of welding are suitable for?NewsNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NewsNov.21,2025

-

Welding Knowledge 6NewsNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NewsNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NewsNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NewsNov.17,2025