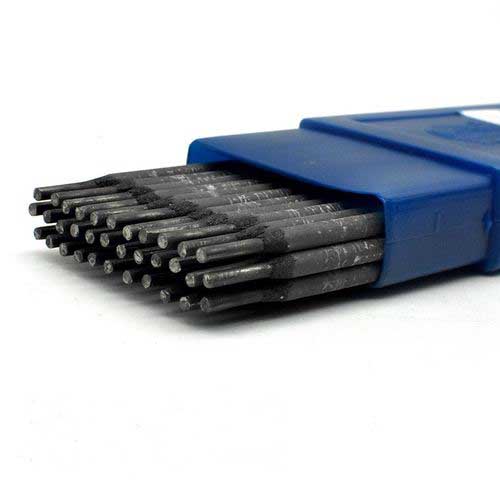

Cast Iron Welding Rod Electrode AWS ENi-Cl | Crack-Resistant

Field Notes on Cast Iron Welding Rod Electrode AWS ENi-Cl

I’ve watched cast-iron repair go from “don’t even try it” to “we’ll turn it around by lunch.” A big part of that shift is the modern ENi-CI nickel stick electrode. This one—let’s call it the Cast Iron Welding Rod Electrode AWS ENi-Cl from Shijiazhuang (origin: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA)—leans on a THZ308 pure nickel core with a graphite-type reducing coating. In plain English: easy striking, stable arc, and, yes, generally no preheat required. Many maintenance crews love it for that alone.

Why it’s trending in maintenance welding

Foundries, pump shops, even heritage restorers are pushing “cold” repair to cut downtime. The Cast Iron Welding Rod Electrode AWS ENi-Cl fits because it resists cracking, runs on AC or DC, and the nickel deposit is nicely machinable. Surprisingly smooth bead profile too—customers say it saves grinding time.

Typical specs (real-world use may vary)

| AWS Classification | ENi-CI (per AWS A5.15) |

| Core/Coating | THZ308 pure nickel core; graphite-type reducing coating |

| Polarity | AC / DC+ |

| Dia. options | 2.5 / 3.2 / 4.0 mm (others on request) |

| Amps (guide) | 2.5 mm: ≈60–90 A; 3.2 mm: ≈80–110 A; 4.0 mm: ≈110–140 A |

| Tensile of deposit | ≈380–450 MPa |

| Hardness (HB) | ≈140–180 HB (machinable) |

| Preheat | Generally not required; keep casting cool |

| Approvals | AWS A5.15 conformance; ISO 9001 factory QA |

Process flow (how welders actually run it)

- Materials: gray cast iron (ASTM A48 types), nodular iron, repair castings and housings.

- Prep: V- or U-groove, drill crack ends, clean to bright metal; slight pre-warm only if condensation risk.

- Method: short beads (10–25 mm), low heat input, peen lightly while hot; skip welding to spread heat.

- Interpass: keep part near ambient; target interpass ≈

- Testing: dye penetrant for surface cracks (ISO 3452); bend/tension samples to AWS A5.15; hardness check.

- Service life: in low-shock duty pumps/gearboxes, repairs often run several seasons; impact/cyclic loads reduce that.

- Industries: mining screens, cement plant fans, farm gearbox housings, foundry tooling, restoration.

Applications and feedback

Common repairs include cracked gearbox feet, worn pump volutes, mis-drilled bosses. Many customers say the Cast Iron Welding Rod Electrode AWS ENi-Cl gives minimal spatter and a calm arc, “less chatter on the lathe” after machining. To be honest, fit-up quality still decides 80% of outcomes.

Vendor snapshot (quick comparison)

| Vendor | SteelToolsChina | Vendor X | Vendor Y |

| MOQ | ≈100–200 kg | ≈250 kg | By carton (flexible) |

| Custom diameters | Yes (2.0–5.0 mm) | Limited | On request |

| Certifications | ISO 9001; AWS conformance statement | ISO 9001 | ISO 9001 |

| Lead time | ≈7–15 days | 2–3 weeks | 1–2 weeks |

Note: indicative, based on publicly available specs; confirm before ordering.

Case snippets and test data

- Foundry jig crack: three 20 mm beads, peened; DPI showed no indications; hardness ≈165 HB; returned to service next shift.

- Pump volute edge build-up: 3.2 mm rod at ~95 A; machined next day; leak test passed 1 bar for 30 min.

- Historic press frame: no-preheat cold repair; interpass

Customization and packaging

Private-label boxes, moisture-resistant vac-packs, and cut-to-length options are available for the Cast Iron Welding Rod Electrode AWS ENi-Cl. If you’re in coastal climates, ask for low-humidity packaging—sounds trivial, but it saves re-baking time.

Standards and compliance (what to check)

Ask for an AWS A5.15 ENi-CI conformance letter, lot MTC, and ISO 9001 certificate. For procedures, qualify to ISO 15614-1 or ASME IX when critical. And, yes, keep a dye-penetrant kit nearby.

Authoritative citations

- AWS A5.15/A5.15M: Specification for Welding Electrodes and Rods for Cast Iron.

- ISO 15614-1: Specification and qualification of welding procedures for metallic materials.

- ISO 3452 series: Non-destructive testing — Penetrant testing.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025