Structural Welding Rod | High Strength, Low Hydrogen

E6010 Rods for Carbon Steel Tube Welding: Field Notes, Specs, and Real-World Picks

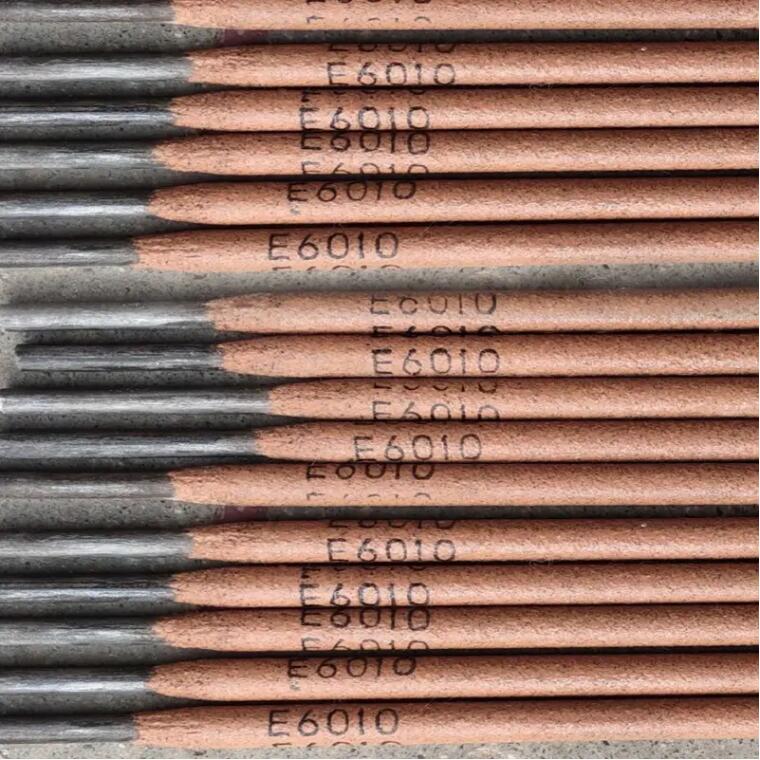

If you weld pipe for a living, you probably have a favorite root-pass stick and a well-worn hood to match. For many crews I talk to, the go-to Structural Welding Rod has been E6010—high-cellulose sodium, DC only, fast-freeze, with enough digging arc to key in a confident root. The model I’m reviewing here is “Welding Rods 6010 for welding carbon steel tubes,” manufactured in NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA. In fact, it’s positioned squarely at pipeline tie-ins, tank work, and maintenance welding where productivity and fit-up forgiveness really matter.

What’s inside E6010 (and why it bites in)

E6010 is a high-cellulose sodium-coated electrode (DC+, typically) that delivers a tight, forceful arc and deep penetration. The cellulose coating generates a protective gas envelope and fast-freezing slag—ideal for open-root passes, vertical-down, and out-of-position work where you can’t babysit a sluggish puddle. To be honest, it’s a rod you feel more than you see: the arc sound, the puddle “keyhole,” the snap. Many customers say the arc start on this model is clean and predictable.

| Product Specs (E6010) | Typical/Notes |

|---|---|

| AWS/ASME Classification | AWS A5.1 E6010; ASME SFA-5.1 |

| Coating | High-cellulose sodium |

| Polarity | DCEP (DC+) |

| Diameter options | ≈ 2.5 / 3.2 / 4.0 mm (real-world availability may vary) |

| Tensile strength | ≥ 60 ksi (≈ 415 MPa) |

| Positions | All positions, strong for downhill pipe roots |

| Storage | Dry, 10–35°C, 40–60% RH; reconditioning not typical like low-hydrogen rods |

Process flow, testing, and standards

Materials: low-carbon steel core wire + cellulose/sodium coating; Method: wire drawing, coating extrusion, controlled drying; QC: chemical composition, coating weight, moisture check, bend tests, tensile pulls, and fillet break tests. Tested to AWS A5.1 and qualified in procedures to API 1104 and ASME Section IX (project-dependent). Typical service life? If stored dry and sealed, unopened cartons hold up well for a year+, though real-world use may vary.

Where it shines

- Pipeline construction and repair (oil, gas, water); tie-ins and hot taps

- Power plant and refinery maintenance

- Structural steel where root access is limited

- Tubes and small-bore carbon steel with imperfect fit-up

Advantages: quick root travel, deep penetration, handles mill scale, and the puddle freezes fast. However, the trade-off is that slag detach can be more “stringy” and you’ll want clean technique. I guess that’s why seasoned pipehands love it: it rewards rhythm.

Case study: municipal gas tie-in

On a city gas project near Shijiazhuang, welders used this E6010 for downhill roots on 12" schedule 40 line pipe, capping with 7010. NDT: 100% RT on tie-ins; repair rate reported at ≈ 1.8%. Welders noted stable arc at 85–95 A (3.2 mm), easy keyhole control, and minimal porosity after proper surface prep. Feedback sounded almost nostalgic: “the rod talks to you.”

Vendor snapshot and customization

Origin: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA. Customization options often include private labeling, pallet configuration, diameter mix, and moisture-barrier packaging upgrades. Certifications: ISO 9001 for quality systems; classification to AWS A5.1. For project work, request mill test certs and batch mechanicals.

| Vendor | Lead Time | Certs | Customization | Notes |

|---|---|---|---|---|

| Steel Tools China (E6010) | ≈ 2–4 weeks | ISO 9001; AWS A5.1 classification | Label, packaging, diameters | Solid pipeline focus, competitive pricing |

| Generic Importer A | 4–6 weeks | Varies | Limited | Price-led; batch consistency varies |

| Brand B (Premium) | Stock/fast | Robust | Yes | Higher cost; very consistent arc |

Bottom line: for crews needing a dependable Structural Welding Rod for pipe roots, this E6010 is a practical, field-tested pick. Pair with a compatible filler for hot pass/cap, follow preheat guidelines, keep surfaces clean, and qualify to your WPS. And yes, keep a box sealed in the truck—just in case.

If your job mixes structural tie-ins and maintenance, a versatile Structural Welding Rod like this can simplify procurement while checking the standards boxes. For sour service or critical pressure, verify PQRs/WPSs and hydrogen control—common sense, but worth repeating.

Standards and references

- AWS A5.1 / ASME SFA-5.1: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- API 1104: Welding of Pipelines and Related Facilities.

- ASME Section IX: Welding, Brazing, and Fusing Qualifications.

- ISO 2560: Covered electrodes for manual metal arc welding of non-alloy and fine grain steels.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025