Why Choose AWS E6011 Electrodes for All-Position, AC/DC?

aws e6011, e6011 electrode, e6011 electrodes is a key solution in the manufacturing industry, specifically within Fabricated metal products and welding materials. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- aws e6011, e6011 electrode, e6011 electrodes Overview

- Benefits & Use Cases of aws e6011, e6011 electrode, e6011 electrodes in welding materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on aws e6011, e6011 electrode, e6011 electrodes from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

aws e6011, e6011 electrode, e6011 electrodes Overview

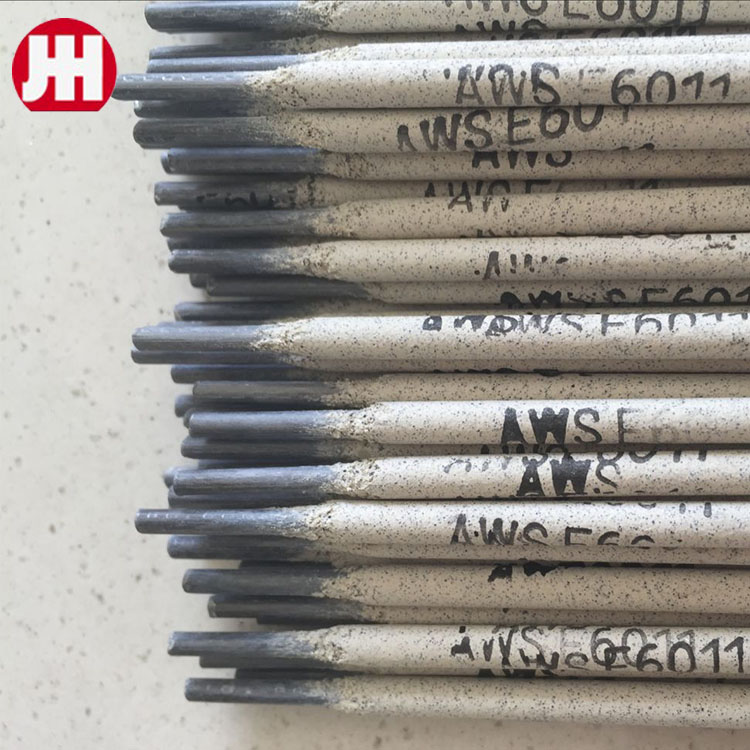

The AWS E6011 classification identifies a cellulosic-coated, all-position mild steel stick electrode engineered for deep penetration and “fast-freeze” performance. In practical terms, an e6011 electrode excels when joints are less than perfect—think rusty, painted, or lightly contaminated steel common across repair, field erection, and MRO environments. Typical properties meet AWS A5.1 requirements with a minimum tensile strength of 60 ksi, and the electrode operates reliably on AC and DCEP, making it compatible with shop power sources as well as portable generator-driven welders.

Available in common diameters such as 2.5 mm, 3.2 mm, and 4.0 mm, e6011 electrodes support flat, horizontal, vertical-up/down, and overhead welding. For B2B decision makers, this versatility translates to fewer SKUs and simplified training across mixed project portfolios. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. manufactures aws e6011 to strict quality standards, focusing on stable arc characteristics, consistent flux composition, and repeatable bead profile from batch to batch—key determinants of productivity and weld integrity in fabricated metal products.

Benefits & Use Cases of aws e6011, e6011 electrode, e6011 electrodes in welding materials

From structural steel repair and farm/construction equipment maintenance to shipbuilding, storage tanks, and pipeline supports, an e6011 electrode is the go-to choice when you need aggressive penetration and dependable fusion through mill scale and light contaminants. The fast-freeze slag enables vertical-down techniques for speed-critical tasks, while a robust, driving arc helps bridge poor fit-up—common in field conditions. For fabrication shops, this means fewer prep steps, reduced grinding, and more first-pass success.

Key advantages include AC/DCEP operability, easy restrike, excellent out-of-position handling, and efficient slag removal. In competitive terms, aws e6011 lets teams move faster with lower power demands, supporting both heavy-duty power sources and compact AC machines in remote locations. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. brings sector-specific expertise with consistent coating adhesion, reliable moisture resistance in packaging, and a product range that covers popular diameters. Their technical team helps customers dial in amperage, polarity, and travel speed to optimize deposition rates and bead appearance across varied joint designs.

Cost, Maintenance & User Experience

Total cost of ownership for aws e6011 is driven less by sticker price and more by throughput: faster travel speeds, minimal joint prep on lightly contaminated steel, reduced rework, and fewer position changes all contribute to higher ROI. Because e6011 electrodes run on AC as well as DCEP, companies can utilize existing shop equipment and portable welders without investing in specialty power sources. Many users in the fabricated metal products sector value the predictable arc starts, low spatter, and easy slag release that shorten post-weld cleanup.

Maintenance and storage are straightforward: keep e6011 electrodes in their original sealed packaging until use, store in a dry, moderate environment, and avoid high-temperature baking that can alter the cellulosic coating’s performance. Clear usage labels and batch traceability from HEBEI YUJINHONG TECHNOLOGY CO.,LTD. support quality assurance programs and help standardize procedures across multiple sites. Feedback from industrial customers consistently highlights reliable arc stability, bead consistency, and reduced time-on-joint—benefits that compound across shift schedules and multi-station operations.

Sustainability & Market Trends in manufacturing

Across manufacturing, sustainability increasingly means doing more with less: less grinding, fewer passes, and reduced energy usage. By allowing effective welding through mill scale and light contaminants, e6011 electrodes cut back on chemical cleaners and excess surface prep. The ability to run on conventional AC power and portable generators helps optimize energy consumption on job sites, while the fast-freeze slag reduces rework that would otherwise burn time, abrasives, and electricity.

Market trends point to strong demand in infrastructure renewal, MRO services, and field fabrication—sectors that favor forgiving, all-position consumables like aws e6011. B2B buyers also prioritize traceability, consistent quality, and responsive supply chains. HEBEI YUJINHONG TECHNOLOGY CO.,LTD. aligns with these priorities by focusing on stable formulations, dependable packaging, and technical guidance that elevates productivity and compliance. With proactive inventory support and continuous product refinement, the company positions its e6011 electrodes as a resilient choice for evolving codes, workforce dynamics, and sustainability targets.

Conclusion on aws e6011, e6011 electrode, e6011 electrodes from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

For fabricated metal products and broader manufacturing, aws e6011 delivers the versatility, arc force, and out‑of‑position performance needed to keep projects moving—on the shop floor and in the field. Backed by HEBEI YUJINHONG TECHNOLOGY CO.,LTD.’s consistent quality and application support, these e6011 electrodes help teams reduce prep time, control costs, and achieve dependable weld integrity. Ready to optimize your welding operations?

Contact us: email: info@steeltoolschina.com

Visit our website: https://www.steeltoolschina.com

-

What is a medium-frequency pulse? What types of welding are suitable for?NewsNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NewsNov.21,2025

-

Welding Knowledge 6NewsNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NewsNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NewsNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NewsNov.17,2025