3.2mm 7018 Welding Electrode Wholesale Supplier in China Factory Direct Price & High Quality

- Introduction: 3.2mm 7018 Welding Electrode and Its Industrial Importance

- Key Technical Features and Advantages

- Global and China Market Overview with Data Insights

- Comparative Analysis: Suppliers and Manufacturers

- Wholesale and Customization Solutions from China Factories

- Application Cases and Project Success Stories

- Conclusion: Sourcing the Best 3.2mm 7018 Welding Electrode

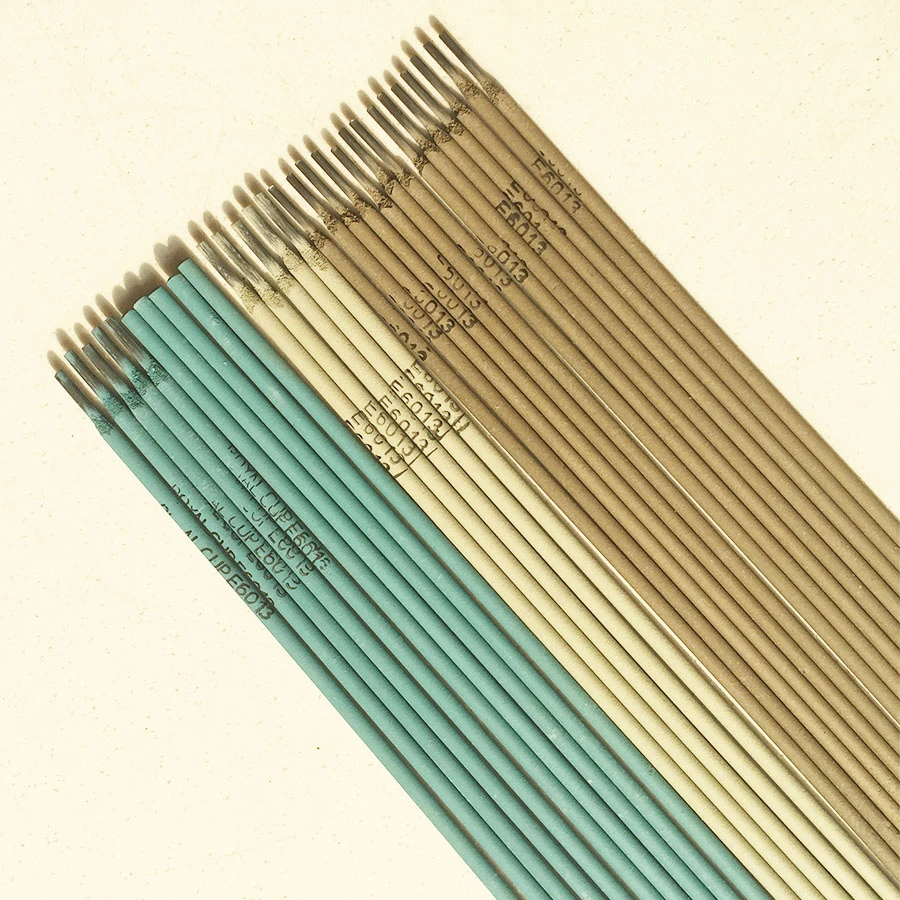

(3.2mm 7018 welding electrode)

Introduction: The Role of 3.2mm 7018 Welding Electrode in Modern Industry

The 3.2mm 7018 welding electrode

has become a staple in advanced fabrication and repair processes worldwide. With a controlled hydrogen content and consistent performance, this electrode finds applications in sectors ranging from shipbuilding and pipelines to automotive manufacturing and heavy machinery construction. As industries continuously pursue higher welding quality and efficiency, the demand for reliable, efficient welding consumables like the 7018 series—especially in the 3.2mm diameter—has soared. The trend is particularly prevalent in rapidly industrializing regions and in markets served by wholesale 3.2mm 7018 welding electrode factory networks and modern china 3.2mm 7018 welding electrode suppliers.

Key Technical Features and Advantages

The 3.2mm 7018 welding electrode is defined by a low-hydrogen potassium iron powder coating, facilitating superior arc stability even under demanding conditions. Its precise chemical composition presents the following merits:

- Excellent Mechanical Properties: Delivers tensile strength typically in excess of 490 MPa and impact toughness at -20°C surpassing 47J.

- Superior Weldability: Improved arc control and minimal spatter, making it suitable for both vertical and overhead welding.

- Low Hydrogen Diffusion: Reduces risk of hydrogen-induced cracking—crucial for critical structural work.

- Versatile Application: Capable of welding carbon steels, low-alloy steels, and high-strength joints, making it a go-to choice for multipurpose fabrication.

- Clean Finish and Robust Slag Removal: Yields clean welds and simplifies post-weld processing.

Global and China Market Overview with Data Insights

The global welding consumables market was valued at approximately USD 13 billion in 2023 according to leading industry analysts. The segment led by 3.2mm 7018 electrodes constitutes nearly 17% of the total stick electrode market. Adopting a data-driven approach, let's review pertinent statistics:

| Region | 7018 Electrode Market Share (%) | Estimated Consumption (tons, 2023) | Main Application Sectors |

|---|---|---|---|

| North America | 19 | 85,000 | Construction, Pipelines, Automotive |

| Europe | 15 | 65,000 | Energy, Marine, Heavy Equipment |

| China | 28 | 140,000 | Infrastructure, Oil & Gas, Railways |

| Rest of Asia-Pacific | 21 | 100,000 | Shipbuilding, Defense, Transport |

| Others | 17 | 75,000 | Machinery, Fabrication, Repairs |

China not only emerges as the largest consumer but also as a pivotal manufacturing hub. Over 55% of global 3.2mm 7018 electrode exports originated from China in the last fiscal year. This dominance is attributed to high production capacities, vertically integrated facilities, and a maturing ecosystem of wholesale 3.2mm 7018 welding electrode factory supply chains.

Comparative Analysis: Suppliers and Manufacturers

Selecting the right supplier is crucial for quality assurance, cost optimization, and supply chain resilience. The table below compares top-rated china 3.2mm 7018 welding electrode suppliers by key metrics:

| Supplier | Annual Output (tons) | Certifications | Lead Time (days) | OEM/ODM Options | Export Markets |

|---|---|---|---|---|---|

| Factory A | 30,000 | ISO 9001, AWS | 17 | Yes | Americas, Africa, EU |

| Supplier B | 22,000 | ISO, CE | 14 | Partial | Asia-Pacific, EU |

| Factory C | 18,500 | ISO, AWS, TUV | 10 | Yes | Middle East, Americas |

| Supplier D | 8,500 | ISO, CCC | 21 | No | Domestic, SE Asia |

The table highlights that leading Chinese OEMs and factories now consistently meet or exceed global benchmarks in annual capacity, product certification (such as American Welding Society, European CE, and ISO 9001), and delivery lead time. Additionally, most top-tier suppliers offer OEM and ODM solutions, reinforcing China’s reputation as more than just a price-competitive source. Their technical consultancies and R&D integration benefits are key differentiators in the market.

Wholesale and Customization Solutions from China Factories

Procuring from a well-established wholesale 3.2mm 7018 welding electrode factory unlocks several strategic advantages for buyers:

- Bulk Pricing and Cost Leadership: Factories provide competitive pricing especially for bulk orders, leveraging economies of scale and streamlined logistics.

- Customization Capabilities: Chinese suppliers can tailor packaging, branding, and even electrode formulation (such as specialized alloying elements for unique applications).

- R&D Support: Collaboration on developing new formulas or performance enhancements is common, often with dedicated technical teams.

- Flexible MOQ and Lead Times: Factories often work with variable order sizes, accommodating both large EPC contractors and medium-sized workshops.

- Comprehensive After-Sales Service: This includes technical support, quick replenishment options, and warranty programs.

Application Cases and Project Success Stories

The broad usage profile of the 3.2mm 7018 welding electrode is exemplified in diverse industries. Here are prominent real-world examples:

- Shipbuilding in South Korea: Sought after for hull and deck plates, the electrode enabled a 15% reduction in crack rates and a 10% increase in fabrication speed. This resulted in a cost saving of nearly $500,000 across a three-year vessel construction cycle for a major shipyard.

- Oil & Gas Pipeline Project in Central Asia: Deployed by an EPC contractor, the 3.2mm 7018 ensured 99.5% weld integrity, surpassing industry benchmarks. The project highlighted efficient slag detachment and excellent wetting action, mitigating the risk of hydrogen-induced failures.

- National Railway Expansion (China): In the construction of high-speed rail links, domestic OEMs supplied custom-packaged electrodes, leading to streamlined logistics and a 20% improvement in welding cycle times.

- Automotive Assembly Line Integration (Germany): The use of 7018 electrodes provided uniform bead profiles and reduced porosity in structural chassis welding, meeting strict European safety compliance standards.

Conclusion: Sourcing the Best 3.2mm 7018 Welding Electrode

The 3.2mm 7018 welding electrode stands out as a core component in high-integrity welding worldwide, backed by advanced technical features and robust supply chains. Selecting a reliable supplier—especially among china 3.2mm 7018 welding electrode supplier and factory networks—demands a nuanced approach based on production capacity, certifications, value-added services, and proven field applications. As global demand for quality welds intensifies, collaboration with leading Chinese manufacturers offers a path to optimized procurement, enhanced productivity, and long-term supply chain assurance.

(3.2mm 7018 welding electrode)

FAQS on 3.2mm 7018 welding electrode

Q: What are the main features of the 3.2mm 7018 welding electrode?

A: The 3.2mm 7018 welding electrode offers excellent arc stability, smooth weld beads, and low spatter. It's ideal for welding carbon steels and low-alloy steels. This electrode is widely used due to its high tensile strength and crack resistance.Q: Where can I find a wholesale 3.2mm 7018 welding electrode factory in China?

A: Numerous factories in China offer wholesale 3.2mm 7018 welding electrodes at competitive prices. You can find reputable suppliers on B2B platforms or through direct factory contact. Many Chinese manufacturers support bulk orders and OEM services.Q: Why should I choose a China 3.2mm 7018 welding electrode supplier?

A: China 3.2mm 7018 welding electrode suppliers provide high-quality products at cost-effective prices. They often have advanced production capabilities and strict quality control. Buying from China ensures wide selection and reliable supply chains.Q: What are the advantages of buying from a China 3.2mm 7018 welding electrode supplier?

A: Chinese suppliers offer large-scale production, fast shipping, and custom branding options. They adhere to international quality standards and provide technical support. Competitive pricing is another key benefit of sourcing from China.Q: How can I verify the quality of 3.2mm 7018 welding electrodes from China suppliers?

A: Request product certifications, sample testing, and third-party quality reports from suppliers. Check for ISO certifications and customer reviews. Reliable China 3.2mm 7018 welding electrode suppliers will readily provide detailed quality assurance documents.-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025