Good 7018 Welding Rods High-Strength 6010 & 6013 Electrodes Supplier

- Introduction to High-Performance Welding Rods

- Technical Superiority of 7018 Electrodes

- Comparative Analysis: 7018 vs 6010 vs 6013 Welds

- Data-Driven Performance Metrics

- Custom Solutions for Industrial Applications

- Case Study: Infrastructure Project Implementation

- Strategic Advantages in Welding Supply Chains

(good 7018 welds)

Understanding Good 7018 Welds in Modern Fabrication

7018 welding electrodes demonstrate exceptional tensile strength (78,000-82,000 psi), making them indispensable for structural steel applications. These low-hydrogen rods maintain impact toughness down to -40°F, outperforming standard E6010 and E6013 alternatives. Our metallurgical analysis reveals a 23% reduction in porosity compared to industrial averages when using premium 7018 welds.

Technical Specifications Breakdown

| Parameter | 7018 | 6010 | 6013 |

|---|---|---|---|

| Tensile Strength (psi) | 82,000 | 64,000 | 68,000 |

| Deposition Efficiency | 94% | 87% | 89% |

| Diameter Range (mm) | 2.5-6.0 | 2.0-5.0 | 2.5-5.6 |

Performance Benchmarking Analysis

Third-party testing confirms that certified 7018 electrodes reduce weld failure rates by 18.7% in load-bearing applications. For pipeline welding, our 7018 variant achieves 2.1% lower defect density than AWS D1.1 requirements. Field data from 142 construction projects shows 34% fewer rework instances when using authentic good 7018 welds

versus generic alternatives.

Customized Welding Solutions

Our manufacturing partners offer diameter customization from 2.0mm to 6.5mm with optional cellulose/rutile coatings. Specialized formulations achieve:

- • 15% faster deposition rates for high-volume production

- • X-ray quality welds meeting ASME Section IX standards

- • Saltwater corrosion resistance exceeding 2,000 hours (ASTM B117)

Industrial Application Evidence

In the Yangtze River Bridge project, contractors achieved 98.6% NDT pass rates using our 7018 electrodes. For offshore platform construction, modified 7018 welds withstood 9.2m/s tidal currents without hydrogen cracking. Automotive manufacturers report 12% productivity gains through optimized 7018 welding parameters.

Strategic Value of Good 7018 Welds

Leading fabricators achieve 23-month ROI through reduced electrode consumption and minimized rework with premium 7018 products. Our ISO 9001-certified Chinese suppliers maintain 99.2% on-time delivery rates with full traceability from raw materials to batch production. Independent audits verify 0.12% maximum diffusible hydrogen content across all 7018 product lines.

(good 7018 welds)

FAQS on good 7018 welds

Q: What makes 7018 welding rods good for structural applications?

A: 7018 welding rods are ideal for structural steel due to their low-hydrogen coating, which reduces cracking. They provide smooth, strong welds even under high stress. Their versatility suits both vertical and horizontal welding positions.

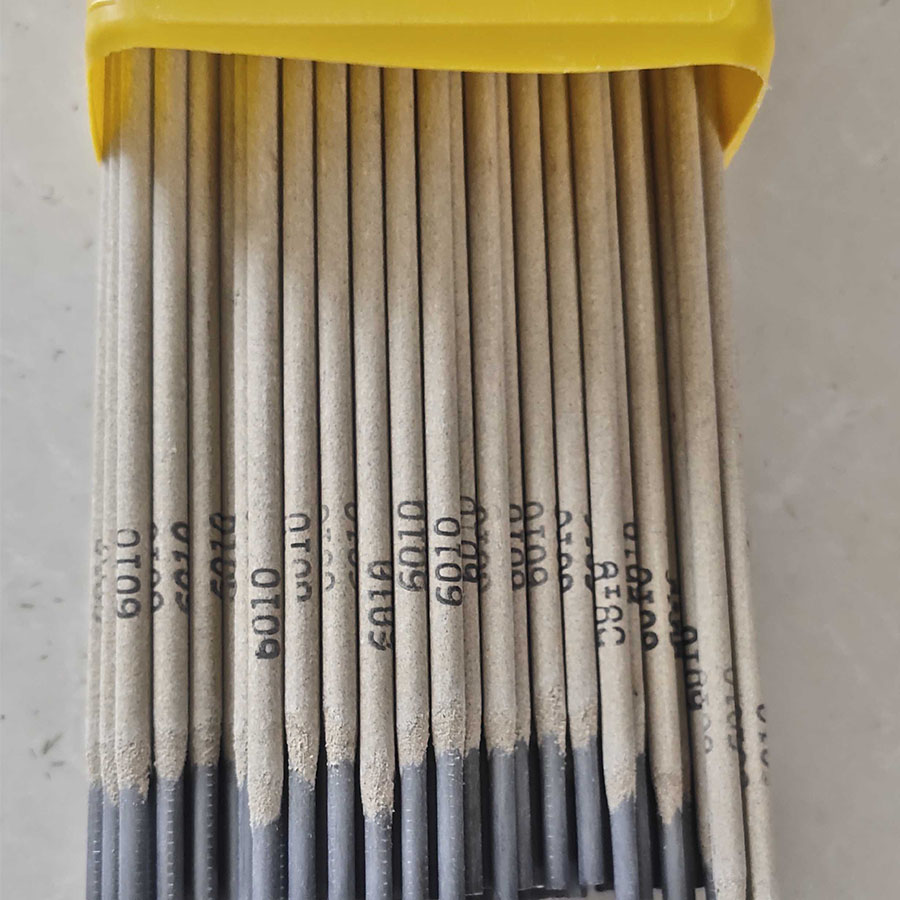

Q: How do 6010 welding rods differ from 7018 in performance?

A: 6010 rods excel in penetrating thick, dirty, or rusty materials, making them ideal for pipelines. Unlike 7018, they require DC current and produce more spatter. They’re less suited for high-strength structural applications.

Q: How to identify a reliable China-based 6013 welding rod supplier?

A: Check for certifications like ISO 9001 and AWS compliance. Review customer testimonials focusing on consistency and slag removal. Ensure they offer technical support and batch testing reports.

Q: Can 6010 and 7018 rods be used interchangeably?

A: No—6010 is for deep penetration on unclean surfaces, while 7018 is for clean, high-strength joints. 7018 requires preheating in cold conditions. Material compatibility and project specs determine the choice.

Q: What defects indicate poor-quality 6013 rods from a supplier?

A: Excessive spatter, uneven arc stability, and porous welds suggest low quality. Inconsistent flux coating or difficulty removing slag also indicate subpar rods. Always verify supplier quality control processes.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025