Rutile Welding Rods | Smooth Arc, Easy Slag, Low Spatter

A Practical Buyer’s Guide to Rutile Welding Rods — and Why E6010 Still Rules for Pipelines

In the real world, purchasing teams often search for Rutile Welding Rods but then end up ordering E6010 for pipeline work. Sounds contradictory? Not really. Rutile rods (think E6013) are famous for their smooth, easy arc and good bead appearance. E6010, on the other hand, is a high-cellulose pipeline workhorse with deep penetration and fast-freezing slag. Different tools for different jobs, as my old foreman liked to say.

Industry trend check (2025)

Global maintenance teams still lean on rutile-coated electrodes for structural and shop fabrication on AC machines, but pipeline contractors overwhelmingly standardize on E6010 root passes with E7010/E7018 fill. Actually, we’re seeing more QA teams asking for documented WPS/PQR packs and lot-level traceability—especially on cross-country lines and tank farms.

Rutile vs. E6010—quick explainer

- Rutile (E6013/E6012): TiO2-based coating, smooth arc, easy re-strike, tidy slag peel, AC/DC. Great for thin sheet, general fabrication, training, light structures.

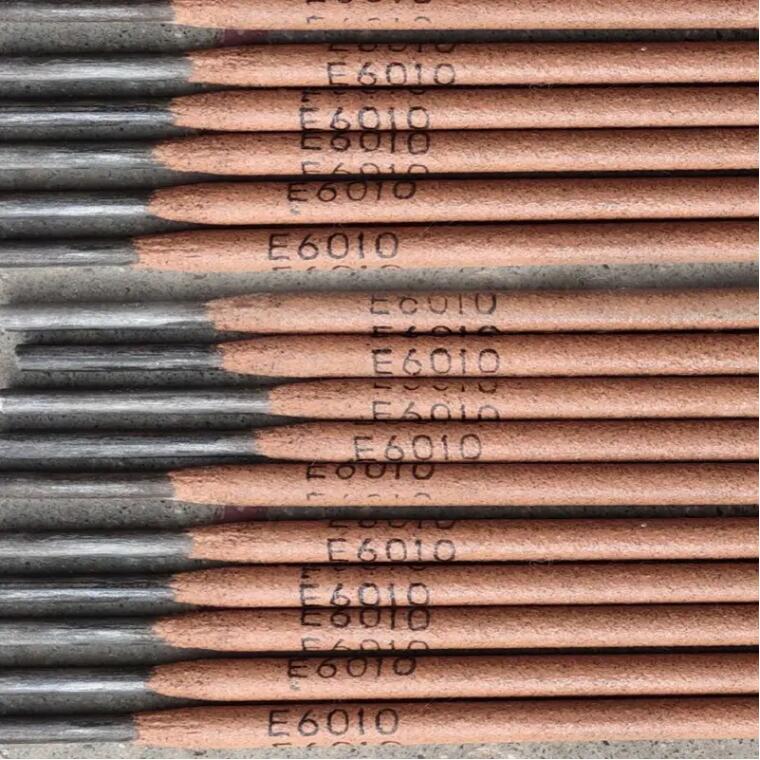

- E6010: High-cellulose sodium coating, DC+ only, aggressive arc, deep penetration, fast-freezing slag—ideal for open-root pipe and out-of-position work.

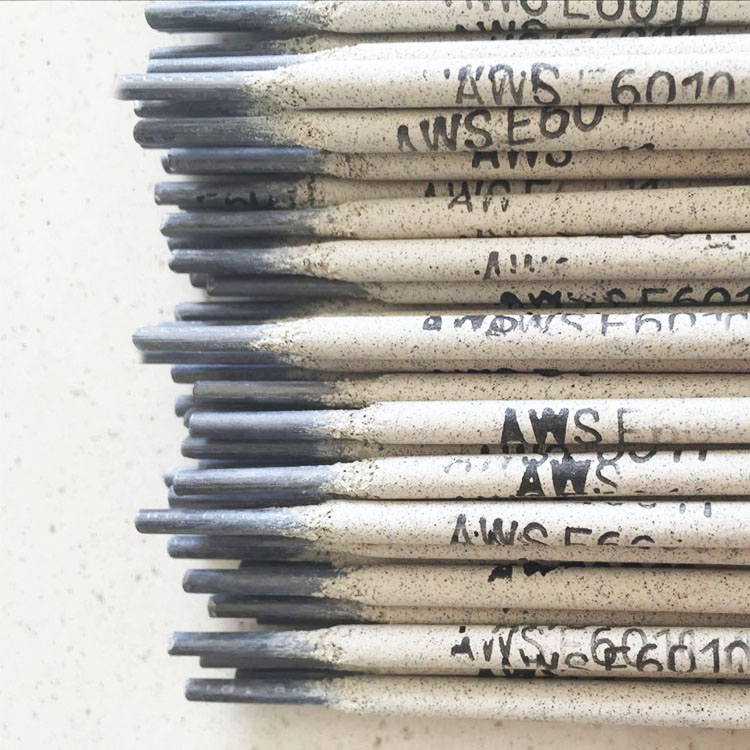

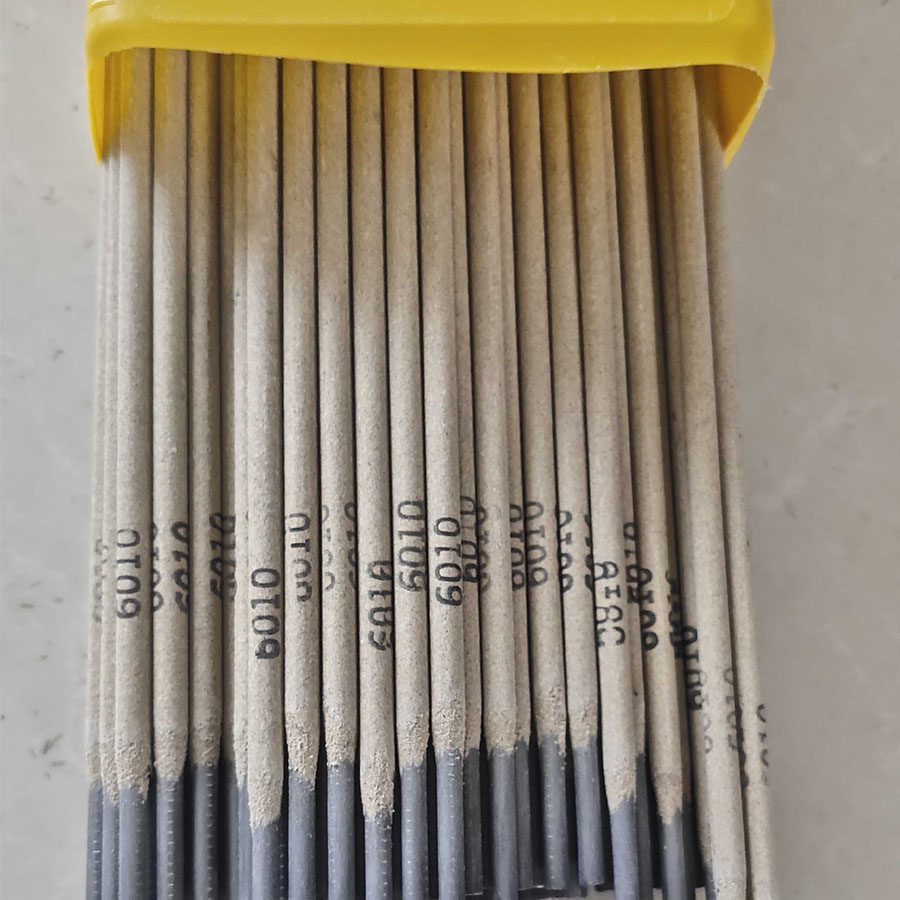

Product spotlight: AWS E6010 Welding Electrodes Sticks (PM PRO-60)

Origin: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA. Designed for pipeline root passes and tie-ins. To be honest, this is the rod you grab when fit-up isn’t perfect and you still need sound fusion.

| Parameter | Spec (≈ real-world) |

|---|---|

| AWS/ASME | AWS A5.1 / ASME SFA-5.1 E6010 |

| Diameters | 2.5 / 3.2 / 4.0 / 5.0 mm |

| Polarity | DC+ only |

| Typical Current | 3.2 mm: 80–110 A; 4.0 mm: 90–140 A |

| Tensile Strength | ≥ 410 MPa (60 ksi) |

| Elongation | ≥ 22% (typical) |

| Applications | Pipeline root, maintenance, out-of-position welds |

Process, testing, and standards (how it’s made and proven)

Materials: low-alloy steel core wire, high-cellulose sodium coating (E6010); rutile rods use TiO2-rich flux. Manufacturing: wire drawing → flux mixing → extrusion → baking → lot coding. Quality checks: diffusible hydrogen (as applicable), moisture content, arc stability, x-ray of test welds, guided bend tests, and tensile pulls per AWS A5.1 and ISO 2560-A. Procedure standards: API 1104 and ASME IX for PQR/WPS. Service life? Not the rod—your weld. With correct parameters and post-weld inspection (VT/RT/UT as required), joints routinely meet design life for pipeline and structural codes.

Where each shines

- Rutile Welding Rods: workshops, sheet work, galvanized repair, light frames, training labs.

- E6010: cross-country pipelines, tie-ins, vertical-down roots, repair in windy sites where fast-freezing slag is a lifesaver.

Vendor comparison (real-world buyer notes)

| Vendor | Core Strength | Certs | Lead Time | Customization |

|---|---|---|---|---|

| Steel Tools China (E6010 PM PRO-60) | Pipeline-focused, stable DC+ arc | AWS A5.1, ISO 2560-A (COC available) | ≈ 2–4 weeks | Branding, packaging, dia. mix |

| Generic Supplier A (Rutile E6013) | Smooth arc on AC | Basic mill certs | ≈ 1–2 weeks | Limited |

| Premium Brand B (Rutile E6013) | Consistent slag peel, top finish | ISO 9001, lot traceability | ≈ 3–5 weeks | Broad SKUs, private label |

Customization and feedback

Common requests: mixed-diameter pallets, moisture-resistant packaging, private labels. Many customers say the PM PRO-60 maintains a crisp root keyhole even on less-than-ideal prep—which, frankly, happens. A site supervisor in Alberta told me, “We switched back to E6010 for the roots; reject rate dropped the same week.”

Case snippet

30-inch API 5L pipeline, Southeast Asia: DC+ E6010 for open-root, visual + bend tests accepted, RT spot checks per API 1104. Fill and cap with low-hydrogen rods. No surprises, which is exactly what you want.

Note: If your job is shop-based with AC welders and thin plate, Rutile Welding Rods (E6013) might be the easier, prettier choice. For field pipe roots, E6010 is still the safer bet.

Authoritative references

- AWS A5.1/SFA-5.1: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- ISO 2560-A: Welding consumables — Covered electrodes for manual metal arc welding of non-alloy and fine grain steels.

- API 1104: Welding of Pipelines and Related Facilities.

- ASME Boiler and Pressure Vessel Code, Section IX: Welding Qualifications.

- TWI (The Welding Institute): Guidance on SMAW electrode classifications and applications.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025