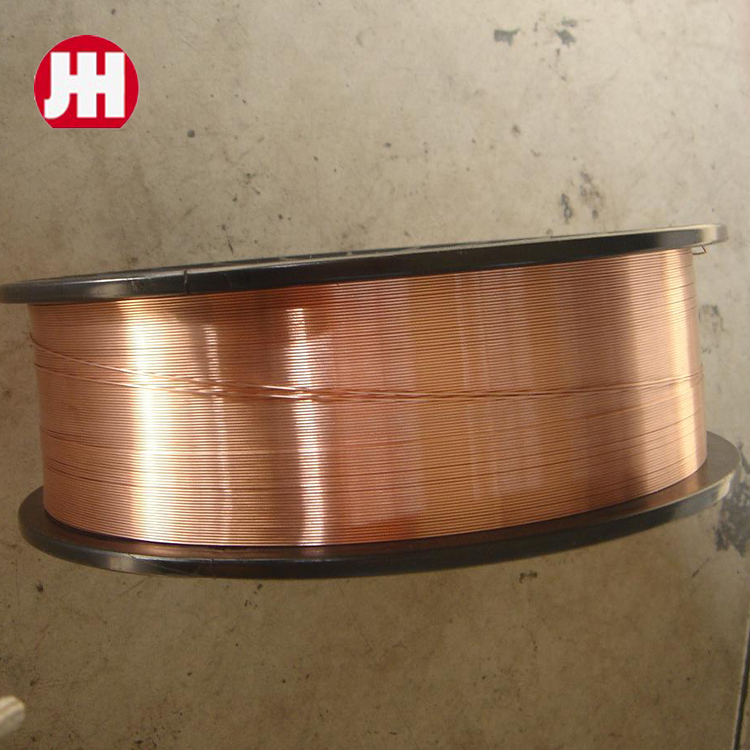

Carbon Steel Welding Wire – Low Spatter, High Strength

Hands-on Notes from the Shop Floor: Picking the Right carbon steel welding wire

If you’ve spent time in a fab shop, you know wire choice makes or breaks the day. The Copper Coated Welding Wire for carbon steel (ER70S-6) from NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA has been popping up in my inbox—customers say it’s clean, predictable, and forgiving. To be honest, I was skeptical. Then I ran a few beads with 80%Ar+20%CO2 and, actually, the puddle control felt calm and the spatter was pleasantly low.

Why ER70S-6 still leads the pack

ER70S-6 is a 500 MPa level wire built for CO2 or M21 mix. In fact, it’s the industry’s “default” for mild and low-alloy steels: high deoxidizers (Si, Mn) help fight mill scale, porosity risk is low, and all-position performance is solid. With this brand, bead appearance is tidy, deposition rate feels brisk, and porosity sensitivity seems small—what many production managers want on Mondays and Fridays alike.

Quick spec snapshot

| Classification | AWS A5.18 ER70S-6; ISO 14341-A G 42 4 M G3Si1 (≈) |

| Typical chemistry (guide) | C ≤0.12; Mn ≈1.4–1.85; Si ≈0.8–1.15 (per AWS ranges) |

| Diameters | 0.8 / 1.0 / 1.2 / 1.6 mm (others by request) |

| Shielding gas | 100% CO2 (C1) or 80%Ar+20%CO2 (M21) per ISO 14175 |

| Mechanical (typical) | YS ≈420–480 MPa; UTS ≈500–560 MPa; Elong. ≈22–28% (real-world may vary) |

| Packaging | 5–15 kg spools; 200–250 kg drums; vacuum-sealed options |

Process flow and testing

- Materials: high-grade wire rod → multi-stage drawing → alkaline cleaning → copper coating → precision layer-winding.

- Methods: CO2/MAG with synergic parameters; preheat only for thicker or higher-carbon joints (≈50–120°C, case-by-case).

- Testing: per AWS A5.18/ASME IX WPS/PQR; ISO 14341 classification; bend and tensile, radiography or UT as required.

- Service life: sealed shelf life ≈12–24 months; store dry, ≤60% RH; re-bake wet spools not advised.

Where it shines

Automotive frames, earthmoving chassis, general fabrication, tanks, HVAC ducting, light ship repair. With straight CO2, expect a bit more spatter but deeper penetration; with M21, smoother arc, nicer face. Many shops choose M21 for out-of-position work—less cleanup, more throughput.

Customization (the practical stuff)

- Wire diameters and spool types (D200/D300); bulk drum kits for robotic cells.

- Copper coat thickness tuning for feedability and contact tip life.

- Private label, barcode, and heat/batch traceability for audits.

Vendor landscape (what we’re hearing)

| Vendor | Certs | Lead Time | MOQ / Custom | Notes |

|---|---|---|---|---|

| SteelToolsChina (this product) | ISO 9001; AWS A5.18 compliant | ≈2–4 weeks | Flexible / Yes | Clean cast/helix, stable arc; good for robots. |

| Vendor A | ISO 9001, CE | 3–6 weeks | Moderate / Limited | Reliable, slightly pricier on small lots. |

| Vendor B | AWS compliant | Stock-dependent | Low / Some | Budget option; watch spool winding quality. |

Mini case notes

- Robotic cell, heavy equipment: switching to carbon steel welding wire ER70S-6 with M21 cut spatter cleanup ≈20% (shop logbook, not a lab test).

- Job shop frames: carbon steel welding wire 1.0 mm handled gaps better after dialing ±10 A hotter and 1–2 L/min more gas—porosity dropped visibly.

- Maintenance welds: straight CO2 on thicker plate gave the root bite they wanted; post-grind time was acceptable.

Final thoughts

If your priority is stable arc, neat beads, and predictable QA, this carbon steel welding wire is a sensible, no-drama pick. Just match parameters to the joint, keep storage dry, and document to AWS/ISO so audits are painless.

Authoritative references

- AWS A5.18/A5.18M: Specification for Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding.

- ISO 14341: Welding consumables — Wire electrodes and weld deposits for gas shielded metal arc welding of non alloy and fine grain steels.

- ISO 14175: Welding consumables — Gases and gas mixtures for fusion welding and allied processes.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025