Mar . 07, 2025 04:21

Back to list

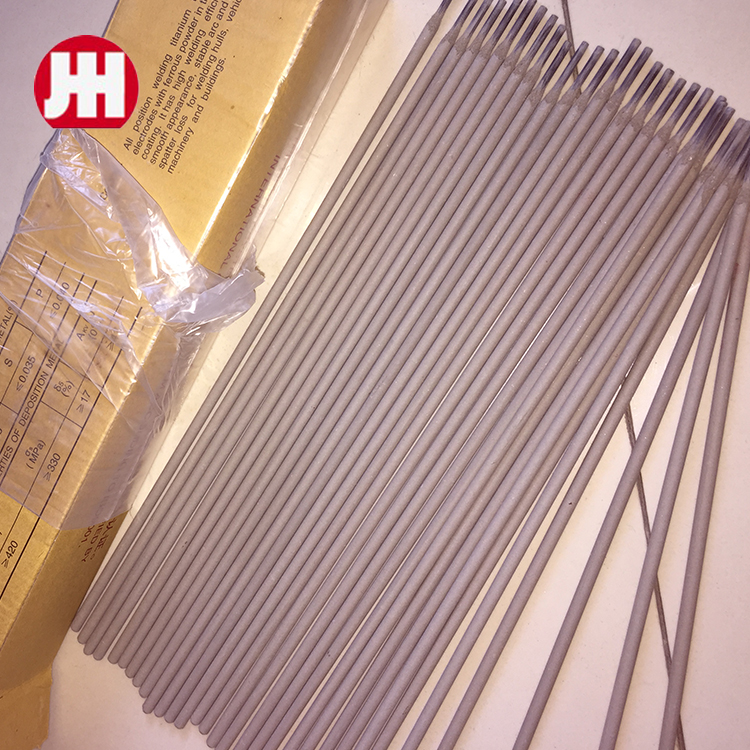

cellulose electrode e6010

The evolution of shipbuilding has experienced numerous advancements over the centuries, but none are as critical today as the refinement of materials and technology involved in the construction process. One notable innovation is the use of cellulose welding rods, particularly the E6010 specification, in the Chinese shipbuilding industry. This article will delve into the practical application and significance of E6010 cellulose welding rods, linking their benefits to the marine construction sector, while establishing their expertise and authority within the industry.

The use of E6010 rods is accompanied by specific technical requirements and expertise, showcasing the importance of professional skill in their application. Shipbuilders specializing in these processes undergo rigorous training to perfect the art of controlling and manipulating these rods to achieve optimal results. This level of specialization highlights the authoritative role these professionals play in advancing the industry. Their ability to maintain structural safety and integrity underpins their trustworthiness and sets a benchmark for global shipbuilding practices. Furthermore, the choice of E6010 cellulose welding rods provides an environmentally considerate approach, aligning with evolving global standards for sustainable construction practices. The cellulose in the coating is derived from natural sources, reinforcing efforts to reduce synthetic inputs, which complements broader ecological initiatives in the shipbuilding industry. By choosing E6010 rods, Chinese shipyards contribute to diminished environmental impact while maintaining high standards of construction quality. Ultimately, the high proficiency with which Chinese shipbuilders employ E6010 welding rods not only underscores their technical expertise but also secures their authoritative status in the global shipbuilding arena. Their success in applying these welding techniques reliably and sustainably reinforces their leadership and integrity within the industry. By consistently delivering maritime vessels that excel in both performance and safety, they cultivate a trustworthy reputation that attracts continued international shipbuilding contracts. In summary, the integration of E6010 cellulose welding rods into Chinese shipbuilding practices exemplifies a harmonious blend of technical know-how, sustainable practices, and reliable execution. Through expert application and authoritative leadership, these welding rods play a pivotal role in shaping the future of shipbuilding—one that upholds quality, insists on structural excellence, and fortifies the industry's commitment to resilient marine construction.

The use of E6010 rods is accompanied by specific technical requirements and expertise, showcasing the importance of professional skill in their application. Shipbuilders specializing in these processes undergo rigorous training to perfect the art of controlling and manipulating these rods to achieve optimal results. This level of specialization highlights the authoritative role these professionals play in advancing the industry. Their ability to maintain structural safety and integrity underpins their trustworthiness and sets a benchmark for global shipbuilding practices. Furthermore, the choice of E6010 cellulose welding rods provides an environmentally considerate approach, aligning with evolving global standards for sustainable construction practices. The cellulose in the coating is derived from natural sources, reinforcing efforts to reduce synthetic inputs, which complements broader ecological initiatives in the shipbuilding industry. By choosing E6010 rods, Chinese shipyards contribute to diminished environmental impact while maintaining high standards of construction quality. Ultimately, the high proficiency with which Chinese shipbuilders employ E6010 welding rods not only underscores their technical expertise but also secures their authoritative status in the global shipbuilding arena. Their success in applying these welding techniques reliably and sustainably reinforces their leadership and integrity within the industry. By consistently delivering maritime vessels that excel in both performance and safety, they cultivate a trustworthy reputation that attracts continued international shipbuilding contracts. In summary, the integration of E6010 cellulose welding rods into Chinese shipbuilding practices exemplifies a harmonious blend of technical know-how, sustainable practices, and reliable execution. Through expert application and authoritative leadership, these welding rods play a pivotal role in shaping the future of shipbuilding—one that upholds quality, insists on structural excellence, and fortifies the industry's commitment to resilient marine construction.

Previous:

Next:

Latest news

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025