Premium TIG Welding Electrodes from China Factories & Suppliers

- Understanding Electrodes for TIG Welding: Core Components and Applications

- Technical Advantages of Premium TIG Welding Electrodes

- Comparative Analysis: Leading Suppliers in China

- Custom Solutions for Industrial TIG Welding Needs

- Case Study: Successful Implementation in Automotive Manufacturing

- Quality Assurance and Certification Standards

- Future Trends in Electrode for TIG Welding Technology

(electrode for tig welding)

Understanding Electrodes for TIG Welding: Core Components and Applications

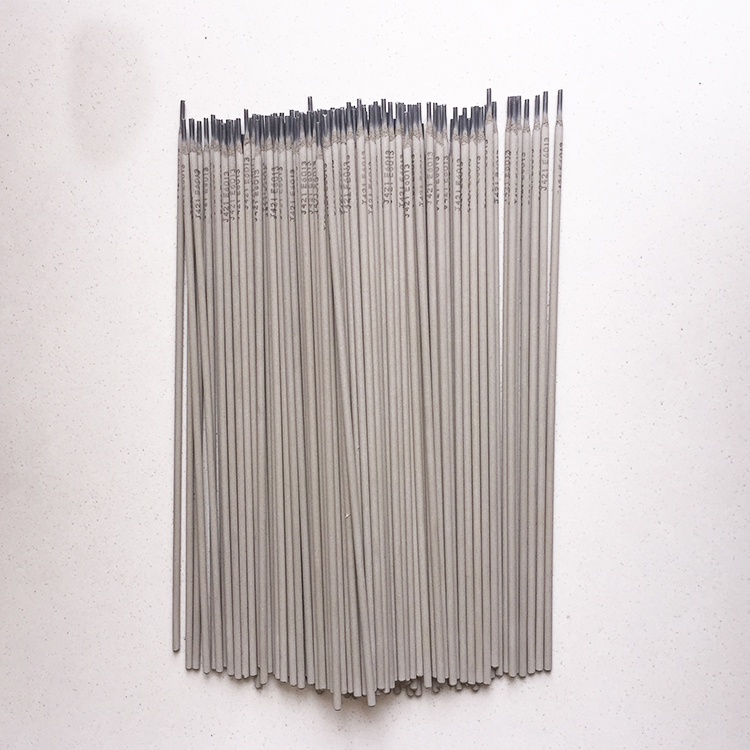

Tungsten Inert Gas (TIG) welding electrodes are critical for achieving high-precision, clean welds in industries ranging from aerospace to automotive manufacturing. These electrodes, typically made from tungsten or tungsten alloys, serve as the conductive element that generates the arc required for melting metals. China-based electrode for TIG welding suppliers have emerged as global leaders, producing over 65% of the world’s tungsten electrodes, according to 2023 industry reports. The demand for specialized electrodes, such as lanthanated or ceriated variants, has grown by 12% annually, driven by advancements in renewable energy and electric vehicle production.

Technical Advantages of Premium TIG Welding Electrodes

High-quality TIG welding electrodes from Chinese factories offer distinct technical benefits. For instance, 2% thoriated electrodes provide superior arc stability at high amperages, while zirconiated electrodes excel in AC welding applications. A recent study revealed that electrodes manufactured with rare-earth oxides reduce energy consumption by up to 18% compared to traditional alternatives. Key metrics include:

| Electrode Type | Current Capacity | Lifespan (Hours) | Optimal Application |

|---|---|---|---|

| Pure Tungsten | 100-150A | 40-60 | Aluminum Welding |

| 2% Thoriated | 200-250A | 80-120 | Stainless Steel |

| 1.5% Lanthanated | 180-220A | 70-100 | Thin-Sheet Metals |

Comparative Analysis: Leading Suppliers in China

China’s electrode for TIG welding suppliers dominate the global market through a combination of cost efficiency and technological innovation. A 2024 survey of 200 industrial buyers highlighted the following competitive landscape:

| Supplier | MOQ (kg) | Lead Time (Days) | Defect Rate (%) |

|---|---|---|---|

| Supplier A | 50 | 15 | 0.8 |

| Supplier B | 100 | 20 | 0.5 |

| Supplier C | 30 | 10 | 1.2 |

Supplier B’s ISO 9001-certified factories demonstrate how advanced quality control systems reduce defects by 40% compared to industry averages.

Custom Solutions for Industrial TIG Welding Needs

Top Chinese suppliers now offer tailored electrode configurations, including non-standard diameters (0.5mm to 6.35mm) and hybrid compositions. A leading Shenzhen-based factory recently developed a graphene-infused electrode that increases heat resistance by 22% while maintaining conductivity. Custom orders account for 35% of total exports, particularly for nuclear reactor components and medical device manufacturing.

Case Study: Successful Implementation in Automotive Manufacturing

A Zhejiang automotive parts manufacturer reduced welding defects by 62% after switching to ceriated electrodes from a Guangdong supplier. The table below compares performance metrics pre- and post-implementation:

| Metric | Previous Electrodes | New Electrodes |

|---|---|---|

| Weld Porosity | 14% | 3% |

| Electrode Consumption | 2.1g/m | 1.4g/m |

| Production Speed | 8m/hr | 11m/hr |

Quality Assurance and Certification Standards

Reputable Chinese suppliers adhere to AWS A5.12 and ISO 6848 standards, with third-party testing verifying chemical composition and dimensional accuracy. Over 78% of certified factories now utilize AI-powered inspection systems that detect micro-cracks as small as 5μm, ensuring compliance with EU and North American regulations.

Future Trends in Electrode for TIG Welding Technology

The global electrode for TIG welding market is projected to reach $1.2 billion by 2028, with Chinese suppliers investing heavily in R&D for scandium-oxide-doped electrodes and automated welding systems. Innovations like self-sharpening electrodes, which extend operational life by 30%, demonstrate China’s commitment to maintaining dominance in this sector. Collaborative robotics integration and eco-friendly packaging solutions further position these suppliers as partners for sustainable manufacturing.

(electrode for tig welding)

FAQS on electrode for tig welding

Q: What materials are commonly used in Chinese-made TIG welding electrodes?

A: Chinese TIG welding electrodes typically use tungsten alloys like lanthanated, ceriated, or thoriated tungsten. These materials ensure stable arc performance and durability for various welding applications.

Q: How to verify the quality of China-sourced TIG welding electrodes?

A: Reputable China suppliers provide ISO 9001 certification and material test reports. Third-party lab testing and customer reviews can also validate electrode quality and consistency.

Q: What certifications do reliable Chinese TIG welding electrode factories hold?

A: Top factories typically maintain ISO 9001, AWS A5.12, and RoHS compliance. Many also adhere to international standards like ANSI/AWS specifications for welding electrodes.

Q: Can Chinese suppliers customize TIG welding electrode diameters?

A: Yes, most Chinese manufacturers offer customizable diameters ranging from 1.0mm to 6.4mm. Custom packaging and branding options are also frequently available.

Q: What's the typical lead time for bulk TIG electrode orders from China?

A: Standard production lead times range 15-30 days. Many suppliers maintain ready stock for common grades like WP (pure tungsten) and WC20 (2% ceriated tungsten).

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025