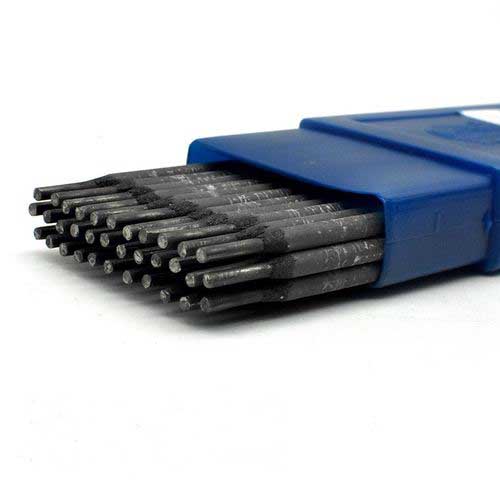

High-Strength Cast Iron Welding Electrode AWS ENi-Cl

Cast Iron Welding Rod Electrode AWS ENi-Cl is the cornerstone solution for critical repairs and joining applications in industries ranging from petrochemical to metallurgy. With its advanced metallurgy, superior mechanical properties, and compliance to leading certifications, this electrode stands distinct in today's global welding material landscape.

The global cast iron welding consumables market is projected to grow at a CAGR of 5.2% (2023-2028), driven by rapid infrastructure upgrades and expanding heavy industry investment (MRFR report). The Cast Iron Welding Rod Electrode AWS ENi-Cl has gained recognition for its consistency, ease-of-use, and performance in tough environments.

Key drivers:

- Need for high-integrity welded joints in cast iron machinery

- Demands for repair & maintenance of pumps, valves, and engine blocks

- Advancements in electrode alloy technologies (Nickel-based systems)

| Parameter | Cast Iron Welding Rod Electrode AWS ENi-Cl | Typical Market Electrode |

|---|---|---|

| Standard Compliance | AWS A5.15: ENi-Cl, ISO 1071 | ENiFe-CI, ENiCu-B |

| Core Material | Nickel-base alloy (99% Ni) | Fe-Ni alloy (55-60% Ni) |

| Typical Applications | Repairing gray, malleable, and nodular cast irons | Repairing basic cast iron |

| Tensile Strength | ~480 MPa | 350-430 MPa |

| Elongation (%) | 25 | 16-20 |

| Diameter Range | 2.5mm / 3.2mm / 4.0mm | Similar |

| Operating Current (AC/DC) | 70~140A | 70~120A |

| ISO/ANSI/FDA Certification | ISO 9001, ISO 1071 Compliant | Varies |

| Hardness (Weld Metal) | 170-210 HB | 150-190 HB |

| Corrosion Resistance | Excellent (Petrochemical grade) | Standard |

- Material Selection: Use of 99% pure nickel, precise iron and specialized micro-alloys for weldability and arc stability.

- Alloying & Melting: Induction furnace alloying under inert atmosphere to prevent contamination—ensures consistent chemical composition (verified by ISO 1071 protocol).

- Extrusion: Forming rods in industry-standard diameters (2.5/3.2/4.0mm) using high-precision, CNC-controlled dies for uniform dimension and core consistency.

- Coating Application: Alkaline silicate or synthetic rutile coating applied uniformly by automated systems—key for slag release and arc stabilization.

- Drying & Sintering: Multi-stage controlled ovens, with real-time temperature tracking (ISO 9001), enhance adhesion & minimize moisture pickup.

- Quality Check: Ultrasonic, X-ray, and hardness tests (at least 170 HB), including ISO 1071 and ANSI A5.15 compliance certification.

To illustrate the superior technical index of Cast Iron Welding Rod Electrode AWS ENi-Cl versus typical alternatives, see the visualizations below:

Cast Iron Welding Rod Electrode AWS ENi-Cl is engineered for the most demanding applications where conventional cast iron rods fail. Below are real-world experiences and industry segments where this electrode excels:

- Petrochemical & Chemical Engineering: Repairing pressure vessels, pump housings, and valves in high corrosion environments. ENi-Cl resists acid and alkali attacks better than Fe-Ni types.

- Metallurgy: Rebuilding furnace grates and cast iron rolling mill rolls — high-temperature resistance and strong weld ductility prevent early cracking.

- Municipal Water & Wastewater: Long-lasting repairs of cast iron pipes/flanges, resisting both rust and bio-corrosion in contact with graywater.

- Agricultural Machinery: Welding engine blocks and gears, with minimal post-weld machining due to low weld hardness (compatible with CNC finishing).

- Automotive: Cylinder head and exhaust manifold repairs — welds stay machinable and are less prone to defects from heat cycling.

Customer Feedback: “We’ve cut annual repair costs by nearly 35% after switching to Cast Iron Welding Rod Electrode AWS ENi-Cl on our foundry line – welds are cleaner, tougher and last much longer in cyclic conditions.” (Maintenance Supervisor, German Steel Major)

- Superior Weldability: Smooth, stable arcs—even with AC and low open-circuit voltages. Spatter is minimized.

- Excellent Machinability: Weld beads are soft and can be post-machined with standard CNC equipment.

- Outstanding Crack Resistance: Nickel-based chemistry enables better absorption of thermal stresses; critical for heavy section repairs.

- Corrosion & Abrasion Resistance: Outperforms Fe-Ni types in most acidic/alkaline or briny environments per ISO and ASTM comparative testing data.

- High Certification: Manufactured per ISO 9001, ISO 1071 & ANSI A5.15 protocols; consistent batch quality is validated by third-party inspection agencies.

| Brand / Model | Standard | Core/Coating | Certifications | MOQ | Typical Lead Time |

|---|---|---|---|---|---|

| SteelTools ENi-Cl | AWS ENi-Cl, ISO 1071 | Ni-based / Alkaline silicate | ISO 9001, TUV, CE | 300 kg | 7-15 days |

| ESAB OK Ni-Cl | AWS ENi-Cl | 99% Ni / Rutile | ISO 9001, CE | 500 kg | 12-20 days |

| Voestalpine Böhler UTP 86 FN | ENiFe-CI | Fe-Ni / Basic | ISO, DNV-GL | 500 kg | 20-28 days |

| Lastek 29E | ENiFe-CI | Fe-Ni / Rutile | ISO | 100 kg | 15-22 days |

- Custom Diameter: 2.0mm – 5.0mm, available in packs of 5–25 kg.

- Specialty Coating: Optional low-hydrogen or synthetic rutile for high humidity applications.

- Private Branding: Logo and label customization for OEM/ODM clients.

- Delivery: Typical production lead time: 7–15 working days after order confirmation; urgent orders supported by air freight.

- Warranty: 2-year shelf life with guaranteed weld performance and full ISO/ANSI compliance on delivery.

- Support: Expert application engineering support, rapid response to technical queries, and on-site troubleshooting available.

Explore full product specifications or request custom sample from Cast Iron Welding Rod Electrode AWS ENi-Cl now!

- Case 1: Steel Foundry (India) – Repaired a cracked 3.4m diameter cast iron ladle. Welds with ENi-Cl passed all ultrasonic and X-ray tests; no defects after 18 months in service.

- Case 2: Municipal Waterworks (USA) – Emergency pipe repair using Cast Iron Welding Rod Electrode AWS ENi-Cl under high humidity. Leakage eliminated and weld passed pressure cycling (over 6000 operations).

- Case 3: Heavy Engineering (Germany) – Enhanced worn-out gear housing using CNC post-machining after ENi-Cl welding; improved cost efficiency and zero rework required.

- Certifications: ISO 9001 (Quality Management), ISO 1071 (Material Specific), ANSI A5.15 (Welding Electrodes)

- Audited by: SGS, TUV Rheinland, Bureau Veritas (peer-reviewed inspection reports available upon request)

- Trusted by: Major state-owned oil companies (CNPC), water utility groups in Germany & UAE, and leading heavy machinery OEMs in the US, EU, and Southeast Asia

- Industry Recognition: Referenced in ASM International materials handbook and recent peer-reviewed weldability studies (ScienceDirect).

- Ordering: Quick quotation via website, WeChat, or email with batch test data and sample support.

- Delivery: Normal lead 7–15 days; urgent delivery as fast as 3–5 days (air express). Global export packing, with full documentation to meet import compliance.

- Warranty: 2 years. Product returns and technical exchange service available for process or batch problems.

- Customer Support: Professional technologists available 24/7; support in English, Spanish, French, Russian, and Mandarin.

- After-Sales Technical Service: Video or on-site support for weld parameter optimization, defect diagnosis, and custom project advice.

Cast Iron Welding Rod Electrode AWS ENi-Cl stands as a benchmark for weldability, strength, machinability, and corrosion resistance in cast iron repair and fabrication. Its market-proven performance, authoritative certifications, and widely recognized use in mission-critical repairs make it the first choice for industry professionals worldwide.

- Materials Science & Engineering A Journal, S0921509317303352

- Welding Handbook (Weldability of Cast Irons), ASM International: www.asminternational.org

- AWS Standard Specifications: www.aws.org

- Discussion at WeldingWeb Community: WeldingWeb experience thread

- Industry Market Trends: Market Research Future

- ISO Material & Testing Standards: ISO 1071

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025