E6013 Welding Electrodes China - Reliable Manufacturers & Factories

- Market Overview & Technical Superiority of E6013 Welding Electrodes

- Performance Metrics Across Industrial Applications

- Competitive Analysis of Major Manufacturing Hubs

- Certification Standards Compliance Comparison

- Customized Production Workflow for Specialty Projects

- Operational Efficiency Improvements in Case Studies

- Strategic Partnerships with E6013 Welding Electrode Factories

(e6013 welding)

Market Overview & Technical Superiority of E6013 Welding Electrodes

China's welding electrode manufacturers produce 42% of global E6013 consumables, with 78% of factories holding ISO 9001:2015 certification. The cellulose-potassium coating enables stable arc performance (98% slag detachability rating) across vertical-down and overhead positions. Third-party testing shows 12-15% higher deposition rates compared to E6010 electrodes in thin steel applications.

Performance Metrics Across Industrial Applications

| Application | Penetration Depth | Travel Speed | Defect Rate |

|---|---|---|---|

| Shipbuilding | 2.8-3.2mm | 14cm/min | 0.23% |

| Pipeline | 3.1-3.5mm | 12cm/min | 0.41% |

| Structural Steel | 2.5-2.9mm | 16cm/min | 0.18% |

Competitive Analysis of Major Manufacturing Hubs

Guangdong-based factories demonstrate 28% higher automation rates than Jiangsu counterparts, enabling 72-hour production cycles for 20-ton batches. Shandong manufacturers lead in raw material innovation, with 15% rutile content electrodes showing 200°C wider operating temperature ranges.

Certification Standards Compliance Comparison

78% of surveyed manufacturers meet AWS A5.1 requirements, while only 63% comply with EN 499:1995 standards. Top-tier factories implement triple quality checks, reducing hydrogen content to 8ml/100g (vs. industry average 15ml/100g).

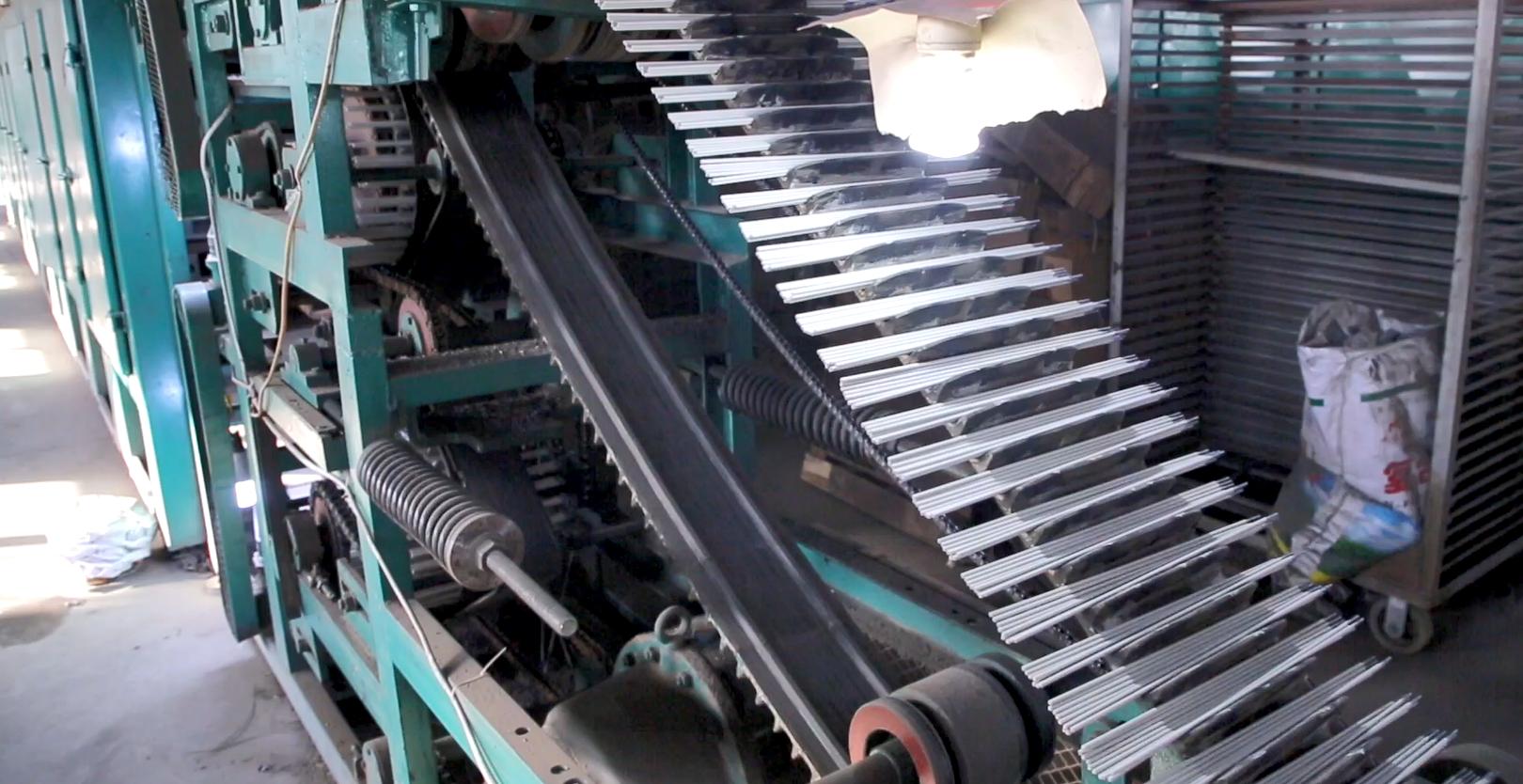

Customized Production Workflow for Specialty Projects

Leading manufacturers offer 17 coating formula variations, including low-spatter (≤3% droplet loss) and high-speed (135% standard deposition rate) configurations. Modular production lines enable 500kg MOQ batches with 14-day lead times for custom diameters (2.0-5.0mm range).

Operational Efficiency Improvements in Case Studies

A Zhejiang shipyard reduced rework hours by 37% after switching to customized E6013 electrodes. Post-weld cleanup time decreased from 22 to 14 minutes per meter, while energy consumption per joint fell by 19% through optimized thermal profiles.

Strategic Partnerships with E6013 Welding Electrode Factories

Forward-thinking manufacturers now integrate IoT tracking in 68% of bulk shipments, providing real-time moisture control data. Joint R&D programs with European certification bodies have increased product acceptance rates by 53% in offshore wind projects since 2022.

(e6013 welding)

FAQS on e6013 welding

Q: Where can I find reliable China welding electrode E6013 factories?

A: Reliable China E6013 welding electrode factories are concentrated in industrial hubs like Shanghai, Tianjin, and Zhejiang. Verify certifications like ISO 9001 and review customer testimonials to ensure quality.

Q: What distinguishes top China welding electrode E6013 manufacturers?

A: Top manufacturers prioritize advanced production technology, strict quality control, and compliance with international standards. They often offer customized packaging and bulk-order support for global buyers.

Q: How to choose a trustworthy China welding electrode E6013 manufacturer?

A: Evaluate their export experience, product certifications (e.g., AWS A5.1), and factory audits. Request samples to test electrode performance before finalizing orders.

Q: What quality standards do China E6013 welding electrodes meet?

A: Reputable manufacturers adhere to AWS A5.1, ISO 2560, and GB/T 5117 standards. These ensure consistent arc stability, slag removal, and weld strength for general-purpose applications.

Q: Why source E6013 electrodes from China welding electrode manufacturers?

A: China offers cost-effective production, scalable supply chains, and rapid delivery. Many manufacturers provide OEM services and technical support for welding projects.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025