e71t 1 shielding gas: CO2 or Ar/CO2 for low spatter?

E71T-1C Gas-Shield Flux-Cored Wire: The Real-World Guide to e71t 1 Shielding Gas

If you’ve ever debated CO2 versus mixed gas on a windy jobsite, you already know the stakes. For anyone researching e71t 1 shielding gas, here’s the candid truth from the floor: the “C” in E71T‑1C points you squarely at 100% CO2, and that choice drives arc behavior, bead shape, and—yes—your bottom line.

Industry snapshot and why CO2 still wins (often)

In shipyards, heavy fab, and structural steel, E71T‑1C remains a workhorse. Many customers say they prefer 100% CO2 (ISO 14175 C1) for better out-of-position performance and excellent penetration, even if spatter control needs a bit more finesse. Mixed gas (Ar/CO2) shines with E71T‑1M, but for e71t 1 shielding gas focused on “C”, you’re really optimizing for robustness and cost. Surprisingly, the total cost of quality often comes out lower with CO2 where fit-up isn’t perfect.

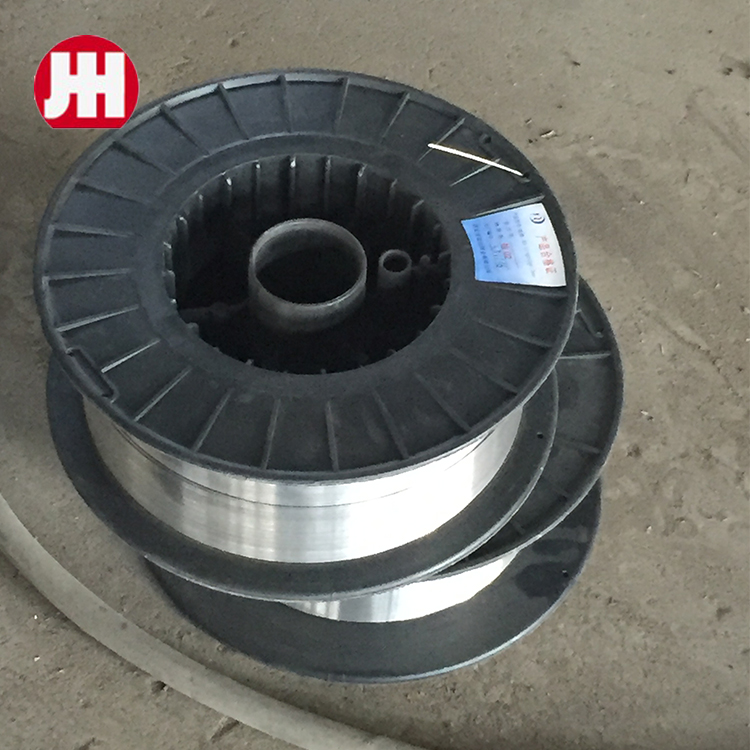

Product at a glance

Product: E71T‑1C Gas Shield Flux Coated Welding Wire (Origin: NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA). Specs traceability is solid: GB/T10045 E501T‑1; ISO 17632‑A‑T422PC2H10; NB/T 47018 E501T‑1; AWS A5.36 E71T1‑C1A2‑CS1. In fact, that alphabet soup matters because engineers sign PQRs and WPSs off those exact designations.

| Classification | AWS A5.36 E71T1‑C1A2‑CS1; ISO 17632‑A‑T422PC2H10 |

| Shielding Gas | 100% CO2 (ISO 14175: C1) — optimized for e71t 1 shielding gas |

| Polarity | DCEP |

| Dia. (mm) | 1.2; 1.4; 1.6 (others on request) |

| Typical Params | 180–300 A; 22–30 V; CO2 flow ≈ 20–25 L/min (real‑world use may vary) |

| Mechanicals | TS ≥ 490 MPa; YS ≥ 420 MPa; EL ≥ 22%; CVN ≥ 27 J @ −20°C (typical values often higher) |

| Diffusible H | H10 class (≈ ≤10 ml/100 g deposited metal) |

Process flow and quality control

- Materials: low‑carbon steel strip, carefully blended rutile flux; light copper coating optional.

- Methods: strip forming → flux fill → seam closure → sizing → heat treatment → precision spooling → vacuum/dry pack.

- Testing standards: AWS A5.36 classification tests; ISO 17632 mechanicals; hydrogen per standard methods; bend tests; macro/RT on procedure plates.

- Service life: sealed spools ≈ 12 months dry; welds in service meet design life when WPS, preheat, and interpass controls are respected.

- Industries: shipbuilding, pressure vessels, structural fabrication, offshore modules, heavy equipment.

Applications and real feedback

- Out‑of‑position fillets on thick plate (CO2 helps with fast-freeze slag).

- Root + fill passes on structural members where fit-up is “not perfect.”

- Customers report smooth arc, good wetting, and “surprisingly clean” slag peel with proper CO2 flow and 15–20° gun angle.

Vendor comparison (quick, honest take)

| Vendor | Shielding Gas Fit | Certs/Standards | Typical CVN | Lead Time | Notes |

|---|---|---|---|---|---|

| SteelToolsChina (E71T‑1C) | 100% CO2, tuned for e71t 1 shielding gas | AWS A5.36, ISO 17632, GB/T, NB/T | ≈ 27–80 J @ −20°C (heat/input dependent) | ≈ 2–4 weeks | Good value; customization available |

| Global Brand X (E71T‑1C) | CO2, also offers “M” variants | AWS/ISO; some marine approvals | ≈ 47–100 J @ −30°C | ≈ 1–3 weeks | Premium pricing |

| Regional Supplier Y | CO2 | AWS listed | ≈ 27–47 J @ −20°C | Stock dependent | Budget; QC varies by batch |

Customization and case notes

Custom spool sizes, moisture‑resistant packaging, and tailored flux chemistry are on the menu. One shipyard shifted from “M” to CO2 on fillet welds and saw ≈ 6–8% deposition efficiency gain due to faster travel speeds. Another pressure‑vessel fab qualified WPS with A5.36 “C1A2‑CS1” and reported consistent CVNs at −29°C after tightening interpass to 150°C. To be honest, dialing in stickout (15–20 mm) and dry gas lines solved most of their spatter woes.

Practical tips for e71t 1 shielding gas success

- Use dry, regulated CO2; keep dew point low to protect hydrogen performance.

- Gun angle 10–20° push, ESO 15–20 mm; tune voltage first, then wire feed.

- Maintain preheat/interpass per WPS; verify with ASME IX/ISO 9606 qualifications.

Authoritative citations

- AWS A5.36/A5.36M: Carbon and Low-Alloy Steel Flux-Cored Electrodes for Gas Shielded Arc Welding.

- ISO 17632: Welding consumables — Tubular cored electrodes for gas shielded metal arc welding of non-alloy and fine grain steels.

- ISO 14175: Welding consumables — Gases and gas mixtures for fusion welding and allied processes.

- ASME Section IX: Welding, Brazing, and Fusing Qualifications.

- GB/T 10045 and NB/T 47018: Chinese standards for flux-cored electrodes and pressure equipment welding materials.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025