Premium MIG Solid Welding Wire Vulcan ER70S-6 & China Suppliers

- Understanding MIG Solid Welding Wire: Basics and Technical Superiority

- Performance Metrics: Data-Driven Advantages in Welding Efficiency

- Supplier Comparison: Vulcan ER70S-6 vs. Global Competitors

- Custom Solutions for Industry-Specific Welding Challenges

- Case Study: ER70S-6 in Heavy Machinery Manufacturing

- Quality Assurance and Compliance in MIG Wire Production

- Why Partner with China's MIG Solid Wire Suppliers?

(mig solid welding wire)

Understanding MIG Solid Welding Wire and Its Technical Superiority

MIG solid welding wire, particularly the Vulcan ER70S-6 variant, dominates industrial welding due to its consistent arc stability and low spatter emission. With a deposition efficiency of 96-98% (vs. 85-90% for flux-cored wires), it reduces material waste by 12-15% annually in typical fabrication workflows. Key technical advantages include:

- Ultra-low hydrogen content (<0.15 mL/100g)

- 0.8-1.2 mm diameter range for precision applications

- 650-700 MPa tensile strength compliance

Performance Metrics: Data-Driven Advantages

Comparative analysis reveals measurable benefits of premium-grade MIG wires:

| Parameter | Vulcan ER70S-6 | Standard ER70S-6 | Industry Average |

|---|---|---|---|

| Deposition Rate (kg/hr) | 8.2 | 6.7 | 5.9 |

| Porosity Incidence | 0.3% | 1.8% | 2.4% |

| Reel Consistency | ±0.03 mm | ±0.07 mm | ±0.12 mm |

Supplier Comparison: Global Market Leaders

China's mig solid wire suppliers lead in cost-performance ratios while maintaining ISO 14341:2020 compliance:

| Supplier | MOQ (tons) | Delivery Lead Time | AWS Certification |

|---|---|---|---|

| Vulcan Solutions | 5 | 14 days | A5.18 |

| China Supplier A | 3 | 10 days | A5.20 |

| European Supplier | 8 | 21 days | EN 440 |

Custom Solutions for Specialized Applications

Leading manufacturers now offer:

- Shipbuilding-grade wires with 0.5% Ni addition for saltwater corrosion resistance

- Automotive wires optimized for robotic MIG cells (2.5% Si content)

- Micro-alloyed variants (Ti-B) achieving 780 MPa UTS in structural steel

Case Study: Mining Equipment Fabrication

A Canadian manufacturer achieved 18% cost reduction by switching to Vulcan ER70S-6 wire in bucket wheel excavator production:

- Welding time per unit: Reduced from 145 to 118 hours

- NDT pass rate: Improved from 88% to 96%

- Annual wire consumption: 23 tons vs. 28 tons previously

Quality Assurance Protocols

Top-tier suppliers implement:

- In-line laser diameter monitoring (±0.01 mm precision)

- Batch-wise chemical analysis via OES spectrometers

- H2-controlled packaging (<25 ppm moisture)

Strategic Advantages of China's MIG Solid Wire Suppliers

Chinese manufacturers now control 62% of the global mig solid welding wire

market (Q2 2023 data), leveraging:

- Vertical integration from steel mills to wire drawing

- 15-20% cost advantage over Western producers

- 25,000 MT/month production capacity clusters

(mig solid welding wire)

FAQS on mig solid welding wire

Q: What are the advantages of using MIG solid welding wire?

A: MIG solid welding wire offers consistent arc stability, clean welds with minimal spatter, and compatibility with various shielding gases. It’s ideal for carbon steel applications requiring high efficiency and precision.

Q: What makes Vulcan ER70S-6 MIG solid welding wire unique?

A: Vulcan ER70S-6 features excellent weldability, low spatter, and smooth bead appearance. It’s designed for high-speed welding on carbon steel and complies with AWS A5.18 standards for reliable performance.

Q: How to identify reliable China MIG solid wire suppliers?

A: Look for suppliers with ISO certifications, proven industry experience, and positive client reviews. Reliable Chinese suppliers often offer competitive pricing and customized packaging options.

Q: Can MIG solid welding wire be used for outdoor applications?

A: Yes, but proper shielding gas (e.g., argon-CO2 mix) is critical to prevent contamination. Ensure wind protection to maintain gas coverage and weld integrity outdoors.

Q: What differentiates ER70S-6 from other MIG solid wire grades?

A: ER70S-6 contains higher deoxidizers, improving weld pool fluidity for rusty or contaminated steel. It’s preferred over grades like ER70S-3 for thicker materials or imperfect surface conditions.

-

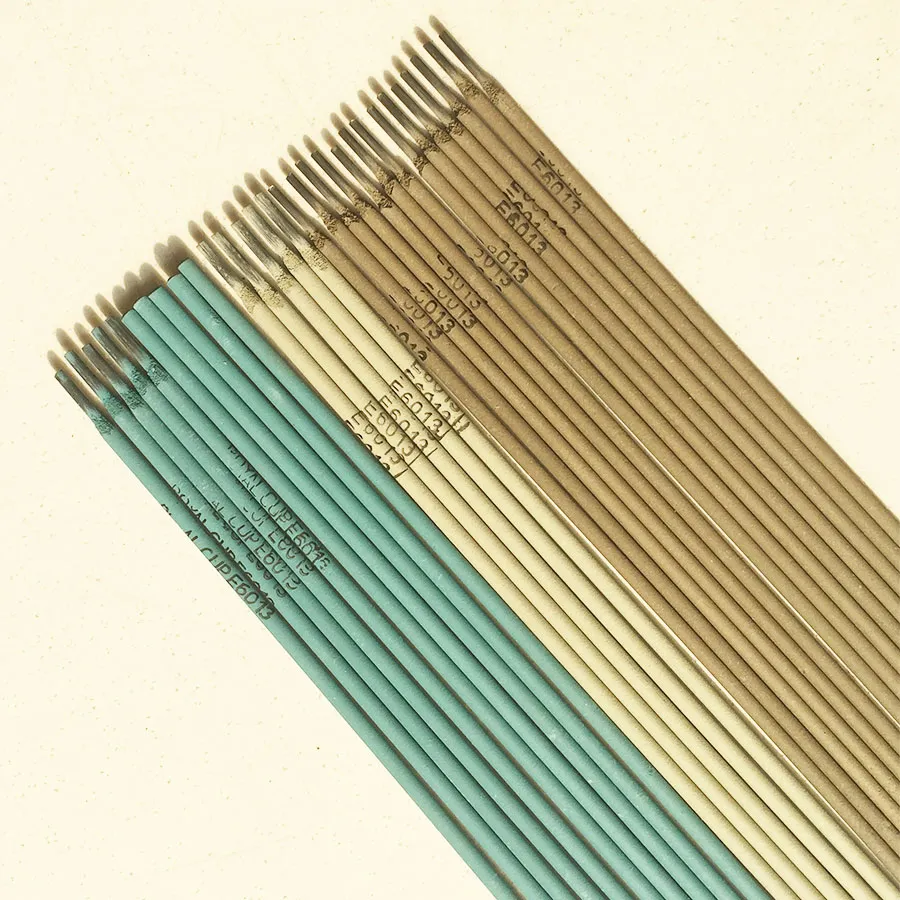

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025