Pipeline Welding Electrodes: Strong, Reliable Pipe Welds

Optimizing Industrial Pipelines: A Deep Dive into High-Performance pipeline welding electrodes

In critical infrastructure projects, the integrity of pipelines is paramount. From oil and gas transmission to complex water supply and drainage systems, the reliability of welded joints directly impacts operational safety, efficiency, and environmental compliance. This necessitates the use of advanced welding consumables, specifically designed to meet the rigorous demands of pipeline construction and repair. Among these, pipeline welding electrodes stand out as a cornerstone technology, offering superior mechanical properties, excellent arc characteristics, and robust performance in challenging field conditions. This comprehensive guide explores the multifaceted world of these specialized electrodes, focusing on technical specifications, application advantages, and their pivotal role in modern industrial endeavors.

Industry Trends in Pipeline Welding Technology

The pipeline industry is undergoing significant transformation, driven by demands for increased efficiency, enhanced safety, and greater environmental responsibility. Key trends influencing the development and application of pipeline welding electrodes include:

- High-Strength Steels: The increasing use of higher-strength pipeline steels (e.g., API 5L X80, X100) requires electrodes capable of matching their mechanical properties, including tensile strength and toughness, while maintaining excellent weldability.

- Automated and Semi-Automated Welding: While manual welding remains prevalent, there's a growing adoption of mechanized and automated welding systems, particularly for long-distance pipelines. This drives demand for consumables optimized for these processes, offering higher deposition rates and consistency.

- Environmental Regulations: Stricter environmental standards necessitate welding processes that minimize fume generation and waste, promoting the development of cleaner burning electrodes and more efficient material transfer.

- Digitalization and Quality Control: Integration of digital tools for weld data monitoring, quality assurance, and traceability is becoming standard, ensuring the highest level of integrity for every welded joint.

- Corrosion Resistance: For pipelines transporting corrosive media or operating in harsh environments, electrodes offering superior corrosion resistance are critical, extending the service life and reducing maintenance costs.

These trends collectively push the boundaries of electrode technology, demanding innovations that deliver improved performance, reliability, and cost-effectiveness in diverse pipeline applications.

The E6010 Cellulose Rod: A Backbone of Pipeline Welding

Among the various types of pipe welding electrodes, the E6010 cellulose welding rod is exceptionally well-regarded for its deep penetration, robust arc, and excellent all-position welding capabilities. Its characteristics make it ideal for root pass welding on pipelines, where a strong, clean penetration is crucial to ensure structural integrity.

Key Characteristics of E6010 Electrodes:

- Cellulosic Flux Coating: The high cellulose content in the flux generates a strong, forceful arc, producing a relatively thin slag that is easily removed. This powerful arc provides excellent digging action, ideal for penetrating deeply into the joint.

- Fast-Freezing Slag: The rapidly solidifying slag makes E6010 suitable for vertical-down welding (a common technique in pipeline work), allowing for faster travel speeds and increased productivity.

- High Deposition Efficiency: While not the highest deposition rate electrode, its characteristics enable efficient root pass welding, minimizing rework.

- Mechanical Properties: E6010 electrodes typically provide welds with minimum tensile strength of 60,000 psi (415 MPa) and yield strength of 48,000 psi (330 MPa), meeting the requirements for many pipeline steels.

These features solidify the E6010's position as a preferred choice for crucial first-pass welds in high-pressure piping and other demanding applications where joint quality is non-negotiable.

The Manufacturing Process of Pipeline Welding Electrodes

The production of high-quality pipeline welding electrodes is a meticulous process, ensuring each rod delivers consistent performance under demanding conditions. It begins with carefully selected raw materials and proceeds through several critical stages:

Process Flow:

- Raw Material Procurement: High-purity steel wire rods (core wire) are sourced, typically low-carbon steel for general-purpose electrodes or alloyed steel for specialized applications. Flux ingredients, including cellulose, titania, silicates, metal powders, and binders, are carefully selected based on the desired electrode characteristics.

- Flux Mixing: The dry flux ingredients are precisely weighed and thoroughly blended. A liquid binder (e.g., sodium or potassium silicate) is then added to form a homogeneous paste. The exact composition of the flux dictates the electrode's arc characteristics, slag properties, and mechanical properties of the weld metal.

- Wire Straightening and Cutting: The coiled steel wire is straightened and cut to precise lengths, forming the core of the electrode.

- Flux Extrusion: This is a critical step. The flux paste is extruded onto the prepared core wire under high pressure. This ensures a concentric and uniform coating thickness along the entire length of the electrode, vital for stable arc performance. Modern machines use sophisticated dies for precision.

- Drying and Baking: The coated electrodes undergo a controlled drying process to remove moisture. For certain electrode types, like low-hydrogen or E6010 cellulosic, a specific baking cycle (temperature and duration) is crucial. For cellulose electrodes, this carefully controlled drying ensures that the cellulose decomposes during welding to provide the necessary shielding gas.

- Quality Control and Testing: Throughout and after manufacturing, electrodes undergo stringent quality checks. These include visual inspection, dimensional checks, concentricity tests, chemical analysis of flux and core wire, and extensive welding performance tests (e.g., arc stability, slag removal, mechanical property testing of weld metal for tensile strength, yield strength, impact toughness). Standards like ISO 2560 (for covered electrodes) and AWS A5.1 (for carbon steel electrodes) guide these testing protocols.

- Packaging: Finished electrodes are packaged in moisture-resistant materials (e.g., vacuum-sealed foil bags, hermetically sealed cans) to protect them from atmospheric moisture, which can degrade performance, especially for low-hydrogen electrodes.

This intricate process, combined with strict adherence to ISO 9001 quality management systems and API (American Petroleum Institute) standards for products used in oil and gas, ensures that each pipeline welding electrodes is fit for its demanding purpose. The typical service life of a correctly applied and maintained pipeline weld can exceed 50 years, demonstrating the long-term reliability required from these consumables.

Figure 1: High-precision flux extrusion is crucial for consistent electrode performance.

Technical Specifications: Pipeline Welding Rod E6010 Cellulose Welding Rod

The performance of an electrode is defined by its detailed technical specifications. Below is a typical breakdown for the Pipeline welding rod E6010 cellulose welding rod, showcasing its robust properties suitable for pipeline applications.

Typical Mechanical Properties of Weld Metal (AWS A5.1 E6010):

| Property | Typical Value | Units | Minimum Requirement (AWS) |

|---|---|---|---|

| Tensile Strength | 500-540 | MPa | 415 MPa (60 ksi) |

| Yield Strength | 380-420 | MPa | 330 MPa (48 ksi) |

| Elongation | 22-28 | % | 22% |

| Charpy V-notch Impact Strength (-29°C) | 40-60 | J | Not specified by AWS A5.1 for E6010, but good toughness is observed. |

Typical Chemical Composition of Weld Metal (Weight %):

| Element | Value (%) |

|---|---|

| Carbon (C) | 0.07 - 0.12 |

| Manganese (Mn) | 0.30 - 0.60 |

| Silicon (Si) | 0.10 - 0.30 |

| Sulfur (S) | < 0.035 |

| Phosphorus (P) | < 0.035 |

Operational Data:

- Welding Positions: All positions, particularly strong in vertical-down.

- Current Type: DC+ (Reverse Polarity).

- Typical Amperage Range (3.2mm / 1/8"): 70-120 Amps.

- Shielding Gas: None (flux coating provides shielding).

These precise specifications ensure the E6010 delivers reliable performance for critical applications in petrochemical, power generation, and water utility sectors.

Technical Advantages and Performance Benefits

The continued reliance on high-quality pipeline welding electrodes stems from their distinct technical advantages, which translate directly into operational benefits for large-scale industrial projects:

- Deep Penetration and Strong Root Pass: Especially for E6010, the robust arc ensures excellent penetration, crucial for achieving full fusion in root passes of thick-walled pipes. This minimizes the risk of lack of fusion defects, a common failure point.

- All-Position Weldability: The ability to weld in all positions, particularly vertical-down, significantly enhances productivity in pipeline construction, allowing welders to work efficiently around the pipe's circumference.

- Tolerance to Imperfect Fit-Up: The powerful arc and rapid slag freezing of cellulose electrodes can accommodate slight variations in joint fit-up, a practical advantage in field welding conditions where perfect alignment is not always achievable.

- Good Arc Stability and Controllability: Welders appreciate the stable arc and puddle control offered by these electrodes, enabling consistent bead placement and reducing welder fatigue.

- Energy Saving: Modern electrode formulations and consistent manufacturing processes optimize arc efficiency, potentially leading to reduced power consumption during welding operations.

- Corrosion Resistance (Enhanced Properties): While E6010 is primarily for general carbon steel, specialized pipeline electrodes offer enhanced alloy compositions to resist specific corrosive media, extending the service life of pipelines in aggressive environments.

- High Weld Metal Quality: Despite the intense arc, advanced cellulose formulations deliver weld metal with excellent mechanical properties, including good ductility and impact toughness, essential for resisting operational stresses and sudden impacts.

These advantages collectively contribute to the long-term reliability and cost-effectiveness of pipeline infrastructure, making the selection of appropriate electrodes a critical engineering decision.

Application Scenarios Across Industries

The versatility and robustness of pipe welding electrodes, particularly types like E6010, render them indispensable across a multitude of heavy industries. Their ability to deliver high-integrity welds in challenging environments makes them a preferred choice for:

- Oil and Gas Pipelines: From long-distance transmission lines (crude oil, natural gas) to gathering lines and process piping in refineries, E6010 is extensively used for root and hot passes. The need for leak-proof, high-pressure joints makes electrode selection critical.

- Petrochemical and Chemical Plants: For process piping handling various chemicals, often under high temperatures and pressures, electrodes must ensure corrosion resistance and structural integrity against aggressive media.

- Water Supply and Drainage Systems: Large-diameter water mains, sewage lines, and industrial water systems require robust welds that can withstand hydrostatic pressure and environmental stressors over decades.

- Power Generation Facilities: In steam lines, cooling water systems, and general plant piping for thermal, nuclear, and hydro power plants, the integrity of welded joints is crucial for continuous operation and safety.

- Shipbuilding and Marine Applications: Piping systems on vessels and offshore platforms, exposed to corrosive seawater and dynamic stresses, benefit from electrodes that provide durable and resilient welds.

- Mining and Slurry Pipelines: Transporting abrasive materials over long distances requires pipelines with exceptional wear and corrosion resistance, demanding specific electrode types for repair and construction.

These diverse applications underscore the demand for versatile and high-performance welding consumables tailored to specific operational environments and material requirements.

Figure 2: Welding operation on a large diameter industrial pipeline.

Vendor Comparison and Selection Criteria

Choosing the right vendor for pipeline welding electrodes is as crucial as selecting the electrodes themselves. The market offers a range of manufacturers, and discerning buyers consider several factors beyond just price:

- Product Quality and Consistency: Reliable vendors ensure consistent chemical composition, flux coating, and welding performance across batches. Certifications like ISO 9001 and adherence to AWS/EN standards are indicators of quality.

- Technical Support and Expertise: A strong vendor provides expert technical assistance, including application guidance, troubleshooting, and training for welders. This is invaluable for optimizing welding procedures and resolving field issues.

- Range of Products and Customization: While a standard E6010 is essential, a comprehensive supplier offers a full suite of pipeline electrodes (e.g., low-hydrogen, specialized alloys) and can develop customized solutions for unique project requirements.

- Supply Chain Reliability: For large-scale projects, consistent and timely delivery is critical. Vendors with robust global logistics networks and sufficient inventory prevent costly project delays.

- Industry Reputation and Experience: Longevity in the market, positive customer feedback, and a track record of supplying major projects are strong indicators of a trustworthy vendor. Companies like SteelToolsChina, with extensive experience in manufacturing and supplying high-performance welding consumables, offer proven reliability.

- Certifications and Compliance: Verification from authoritative bodies (e.g., Lloyd's Register, DNV, ABS) for specific product lines ensures compliance with international maritime and industrial standards.

Evaluating Supplier Capabilities:

When comparing potential suppliers, consider their R&D investment, production capacity, and how quickly they can adapt to emerging material technologies. A vendor comparison might look like this (illustrative, not specific companies):

| Feature | Leading Global Manufacturer X | Specialized B2B Supplier (e.g., SteelToolsChina) |

|---|---|---|

| Product Range for Pipelines | Extensive, covering all types. | Focused on high-performance E6010 & specific pipe welding needs. |

| Customization Capability | Limited for standard products, high MOQ. | High flexibility for specific alloy needs or coating modifications. |

| Technical Support | Global, general technical support. | Dedicated, specialized support, direct access to engineers. |

| Lead Time & Logistics | Standard lead times, vast distribution network. | Often faster for specific batches, flexible shipping options. |

| Cost-Efficiency | Premium pricing for brand. | Competitive pricing with high performance. |

Figure 3: Quality control testing ensures each electrode meets rigorous standards.

Customized Solutions for Unique Project Demands

While standard E6010 pipeline welding electrodes serve a broad range of applications, many industrial projects present unique metallurgical, environmental, or operational challenges that necessitate customized solutions. Leading manufacturers understand this need and offer tailored electrode development:

- Alloy Modifications: Adjusting the core wire and flux composition to achieve specific weld metal properties, such as enhanced toughness at cryogenic temperatures, increased resistance to hydrogen-induced cracking, or superior creep resistance for high-temperature service.

- Optimized Flux Coatings: Tailoring the flux to improve specific welding characteristics, such as arc stability for automated processes, reduced spatter, easier slag removal, or improved moisture resistance for specific storage conditions.

- Diameter and Length Variants: Producing electrodes in non-standard diameters or lengths to fit specialized welding equipment or tight access areas, thereby improving welder efficiency and reducing waste.

- Packaging Solutions: Developing custom packaging for extreme climates, extended shelf life, or to meet specific logistics requirements of remote project sites.

Engaging with a manufacturer capable of delivering customized pipe welding electrodes ensures optimal performance and compliance for even the most stringent project specifications, often leading to significant cost savings through improved weld quality and reduced rework.

Application Case Studies

Real-world applications best illustrate the impact of high-quality pipeline welding electrodes. Here are examples where the E6010 cellulose welding rod, or similar specialized pipeline welding electrodes, played a critical role:

Case Study 1: Transcontinental Gas Pipeline Expansion

A major energy company undertook a multi-billion dollar expansion of its natural gas pipeline network across challenging terrain. The project involved welding thousands of kilometers of API 5L X70 steel pipe, primarily utilizing vertical-down welding for speed and efficiency. E6010 cellulose electrodes were selected for the crucial root pass due to their deep penetration, consistent arc, and fast-freezing slag, which allowed for high travel speeds while maintaining excellent fusion. Rigorous NDT (Non-Destructive Testing) revealed exceptionally low defect rates in the root passes, contributing to on-schedule completion and minimizing costly repairs.

Case Study 2: Offshore Oil Platform Riser Installation

For the installation of new risers connecting an offshore oil platform to subsea pipelines, specialized low-hydrogen pipeline welding electrodes were required to weld high-strength low-alloy (HSLA) steels. The electrodes needed to provide superior impact toughness at sub-zero temperatures and resist hydrogen cracking in a highly corrosive marine environment. A custom-formulated electrode, certified to ABS standards, ensured the integrity of the critical riser welds, providing robust performance against wave action, currents, and deep-sea pressures.

Case Study 3: Municipal Water Infrastructure Upgrade

A large metropolitan area initiated an upgrade of its aging cast iron and steel water main infrastructure. For connecting new sections of ductile iron and carbon steel pipe, E6010 electrodes were extensively used for their reliable performance on a variety of materials and joint configurations. The ease of use, coupled with the robust mechanical properties of the weld metal, ensured long-lasting, leak-proof joints critical for urban water supply, reducing future maintenance costs and ensuring public health.

Figure 4: Pipeline construction in remote or challenging geographical areas.

Frequently Asked Questions (FAQ)

Q1: What makes E6010 electrodes ideal for pipeline root passes?

A1: E6010 electrodes are characterized by a deep, penetrating arc and a fast-freezing, thin slag. This combination allows for excellent fusion and penetration into the root of the joint, even with slight gaps or misalignment, creating a strong, reliable first pass. Its ability to perform well in vertical-down positions also contributes to speed and efficiency in pipeline welding.

Q2: What is the typical service life of welds made with these electrodes?

A2: When applied correctly to suitable base materials and following industry standards (e.g., API 1104, ASME B31.x), welds made with high-quality pipeline welding electrodes can have a service life exceeding 50 years. This longevity is supported by robust mechanical properties, corrosion resistance, and proper operational maintenance of the pipeline.

Q3: How do environmental factors affect electrode storage and performance?

A3: Moisture absorption is the primary concern, especially for low-hydrogen electrodes, which can lead to hydrogen-induced cracking. E6010 cellulose electrodes are less sensitive but should still be stored in dry conditions. Proper storage in original, sealed packaging, and re-baking (if required per manufacturer guidelines) are crucial to maintain performance and prevent weld defects.

Q4: Are there specific safety considerations when using pipeline welding electrodes?

A4: Yes, standard welding safety protocols apply, including proper ventilation to dissipate fumes, use of appropriate Personal Protective Equipment (PPE) such as welding helmets, gloves, and flame-retardant clothing, and ensuring a safe work environment to prevent electrical hazards and burns. Always refer to the electrode's Material Safety Data Sheet (MSDS) and relevant safety standards.

Lead Time, Warranty, and Customer Support

Understanding logistics and support is vital for B2B procurement. As a leading supplier of pipeline welding electrodes, SteelToolsChina is committed to transparency and reliability:

Lead Time & Fulfillment:

- Standard Products: Typically 7-14 business days for common diameters and types, depending on order volume and destination.

- Customized Solutions: Lead times for bespoke orders will be quoted based on complexity, material sourcing, and testing requirements, generally ranging from 3-6 weeks after design approval.

- Expedited Shipping: Available upon request, with additional charges, for urgent project needs. Our robust logistics network ensures efficient global delivery.

Warranty Commitments:

All our pipeline welding electrodes are guaranteed against manufacturing defects for a period of 12 months from the date of purchase, provided they are stored and used according to manufacturer specifications. This warranty covers material and workmanship. For any performance issues attributable to manufacturing flaws, SteelToolsChina commits to replacement or credit at no additional cost.

Dedicated Customer Support:

- Technical Assistance: Our team of welding engineers provides expert advice on electrode selection, welding procedures, and troubleshooting. Contact us via phone or email for prompt support.

- Order Tracking: Customers receive detailed order confirmations and tracking information to monitor their shipments from dispatch to delivery.

- After-Sales Service: Beyond initial purchase, we offer ongoing support, including product training and performance evaluations, to ensure maximum satisfaction and optimal project outcomes.

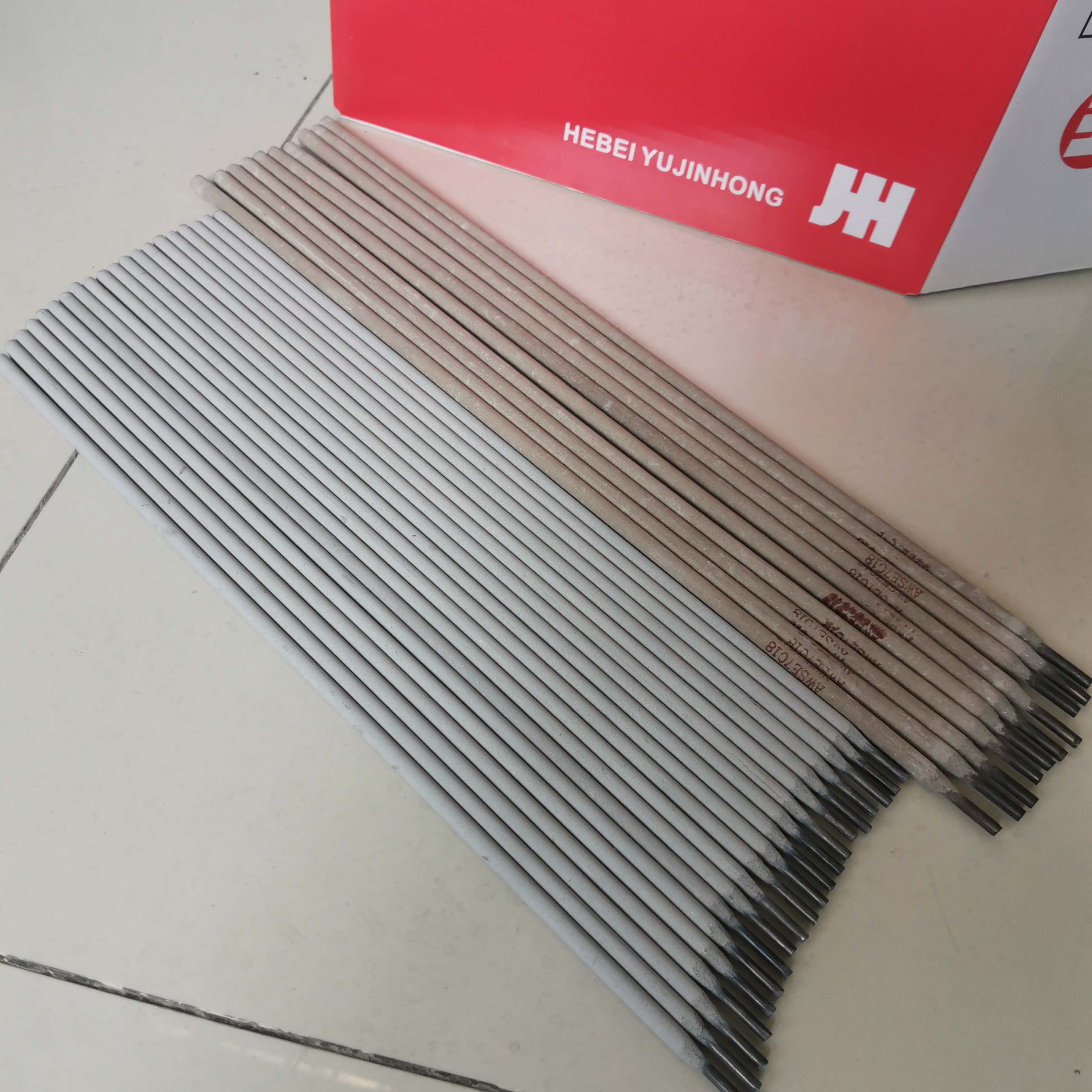

Figure 5: Packaged E6010 cellulose welding rods ready for dispatch.

Conclusion

The consistent evolution of pipeline welding electrodes is a testament to the ongoing demand for greater integrity, efficiency, and safety in pipeline construction and maintenance. From the foundational E6010 cellulose rod to advanced low-hydrogen and alloyed options, these consumables are engineered to meet the stringent requirements of modern industrial infrastructure. By understanding the intricate manufacturing processes, technical specifications, diverse application scenarios, and the crucial role of reliable vendors, B2B decision-makers can ensure the selection of welding electrodes that guarantee long-term performance and uphold the highest standards of quality for critical pipeline projects worldwide.

References

- American Welding Society (AWS) A5.1/A5.1M:2017, Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- International Organization for Standardization (ISO) 2560:2020, Welding consumables - Covered electrodes for manual metal arc welding of non-alloy and fine grain steels - Classification.

- American Petroleum Institute (API) Standard 1104, Welding of Pipelines and Related Facilities.

- The Welding Handbook, 9th Edition, Volume 1: Fundamentals of Welding, AWS, 2001.

- Lancaster, J.F. (1993). Metallurgy of Welding, 5th ed. CRC Press.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025