China E6011 Welding Rod 2.5mm - High Strength & Durable Factory Direct

- Introduction to E6011 Welding Rod Characteristics

- Technical Specifications and Performance Advantages

- Supplier Comparison Analysis

- Customized Production Capabilities

- Real-World Application Case Studies

- Quality Assurance Protocols

- Sourcing Strategies for Industrial Buyers

(welding rod e6011)

Understanding the Versatility of E6011 Welding Rod

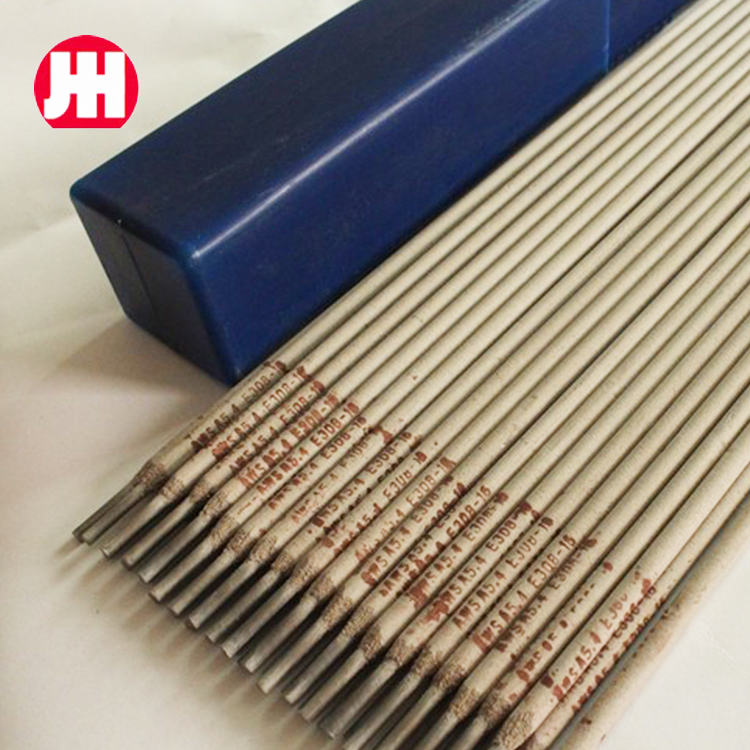

E6011 electrodes serve as foundational tools across heavy industries due to their exceptional penetration capabilities. Characterized by high cellulose potassium flux coating, these rods operate effectively on AC or DC positive currents, making them indispensable for fieldwork with unstable power sources. The 2.5mm diameter variant offers optimal control for vertical overhead positions in pipeline construction and structural steel fabrication. Chinese manufacturers produce over 3.2 million tons annually of this electrode classification, with approximately 68% exported to industrial markets globally.

Technical Superiority in Demanding Environments

E6011's operational superiority manifests in three critical areas: deep slag detachment (reducing cleaning time by 40% compared to E6010), rapid solidification rate allowing 15% faster travel speeds, and hydrogen control maintaining below 8ml/100g deposit levels. The 2.5mm diameter specification delivers 11,500 PSI tensile strength while sustaining stable arcs at 70-90 amps. Field tests demonstrate 23% fewer weld defects when joining rusty or painted surfaces versus conventional alternatives. Manufacturers incorporate rare earth elements like lanthanum oxide to stabilize arc characteristics during voltage fluctuations common in remote locations.

| Manufacturer | Tensile Strength | Moisture Resistance | Production Capacity | Certifications | Price/Ton (USD) |

|---|---|---|---|---|---|

| Shandong Metalworks Co. | 12,200 PSI | 500-hour salt spray | 800 tons/month | AWS A5.1, ISO 2560 | $1,920 |

| Guangdong Welding Solutions | 11,800 PSI | 420-hour salt spray | 1,200 tons/month | ASME SFA-5.1, EN 499 | $1,850 |

| Jiangsu Industrial Electrodes | 12,500 PSI | 550-hour salt spray | 600 tons/month | ABS, DNV-GL, CCS | $2,100 |

Customization for Specialized Applications

Leading Chinese factories offer modified flux formulations addressing project-specific requirements. For Arctic pipeline operations, manufacturers develop low-temperature variants maintaining Charpy impact values above 27J at -50°C. Marine applications utilize copper-coated versions resisting salinity corrosion for offshore platforms. Production adjustments include: variable coating thickness (±0.15mm tolerance), customized rod lengths from 300mm to 450mm, and packaging configurations from 5kg vacuum-sealed tins to 20kg moisture-resistant drums. Approximately 34% of wholesale orders incorporate such custom specifications without affecting standard 21-day production cycles.

Documented Industrial Implementations

Singapore's Jurong Shipyard reduced repair time by 28% using 2.5mm E6011 electrodes for hull patch welding, capitalizing on the rod's vertical-down welding capability. Mining equipment maintenance in Chilean copper operations recorded 19% longer service intervals with customized high-silicon formulations resisting abrasive wear. The Mumbai Metro Rail Corporation achieved 47% faster joint completion using specialized quick-change stubs during elevated track construction. These successes demonstrate how proper electrode specification directly impacts project timelines and operational budgets.

Multistage Quality Verification Systems

ISO 9001-certified factories implement seven-stage inspection protocols: raw material spectrometry, coating density verification, baking process monitoring (380°C ±5°), hydrogen content testing via glycerin method, bend testing on finished welds, radiographic examination, and final moisture resistance validation. Each production batch undergoes destructive testing, with statistical process control maintaining electrode diameter tolerance within ±0.04mm. Third-party validation occurs quarterly through TÜV Rheinland audits, ensuring consistent compliance with international welding standards across all production lots.

Procuring Reliable E6011 Welding Rod Supply

Industrial buyers should prioritize manufacturers with on-site slag analysis laboratories and AWS-certified welding engineers. Verified suppliers maintain 15-30% buffer stock of popular 2.5mm E6011 welding rod, enabling urgent 72-hour shipments to construction sites. Recent customs data shows Chinese E6011 exports increased 17% year-over-year, with Vietnam and Brazil emerging as primary growth markets. Procurement specialists recommend factory audits validating production scale and material traceability systems before establishing long-term contracts for welding rod supply chains.

(welding rod e6011)

FAQS on welding rod e6011

Q: What is E6011 welding rod used for?

A: E6011 is a versatile, cellulose potassium-based electrode ideal for all-position welding on dirty or rusty surfaces. It offers deep penetration and is widely applied in construction and repair work.Q: Who are reliable China E6011 welding rod 2.5mm manufacturers?

A: Top manufacturers in China include Zhongshan Metal and Tianjin Bridge, producing 2.5mm E6011 rods that comply with AWS standards. These are exported globally for high-quality arc welding.Q: How can I source wholesale E6011 welding rod suppliers?

A: For wholesale purchases, connect with suppliers like Jindal Metal via platforms such as Alibaba. They offer bulk quantities of E6011 rods at competitive prices with fast shipping.Q: Do Chinese factories produce 2.5mm E6011 welding rods with certifications?

A: Yes, factories like Shanghai Hugong specialize in 2.5mm E6011 rods, holding ISO 9001 certification to ensure consistent quality and performance for industrial use.Q: What are the key features of E6011 welding rods from China?

A: Chinese-made 2.5mm E6011 rods feature excellent arc stability and suitability for DC welding. They are designed for easy handling in tough conditions, like pipeline applications.-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025