Suppliers of High-Quality 308L Welding Rods for Optimal Performance and Durability

Understanding 308L Welding Rod Suppliers A Comprehensive Guide

Welding is a critical process in various industries, especially in manufacturing and construction, where the integrity of a structure relies heavily on the quality of welds. Among the varieties of welding rods available in the market today, the 308L welding rod is particularly noteworthy for its versatility and effectiveness in stainless steel applications. This article delves into the significance of 308L welding rods and the role of suppliers in ensuring high-quality welding solutions.

What is a 308L Welding Rod?

The 308L welding rod is a type of filler metal used primarily for welding stainless steel. It is composed of a low carbon version of the 308 alloy, which contains a blend of chromium and nickel, making it highly resistant to corrosion and oxidation. The L in 308L stands for low carbon, which helps to minimize the risk of carbide precipitation during welding, thereby preserving the corrosion-resistant properties of stainless steel.

308L welding rods are ideal for a variety of applications, including food processing equipment, piping, and automotive components

. Their ability to provide strong, ductile welds makes them a preferred choice among welders working with stainless steel.The Importance of Choosing the Right Supplier

When it comes to purchasing 308L welding rods, selecting the right supplier is paramount. A reputable supplier ensures that the materials meet the necessary industry standards and specifications, which is crucial for maintaining the quality and safety of welds. Here are several factors to consider when looking for reliable 308L welding rod suppliers

1. Quality of Products Always check for suppliers that offer certified and tested materials. The welding rods should conform to standards set by organizations such as the American Welding Society (AWS) and the American National Standards Institute (ANSI).

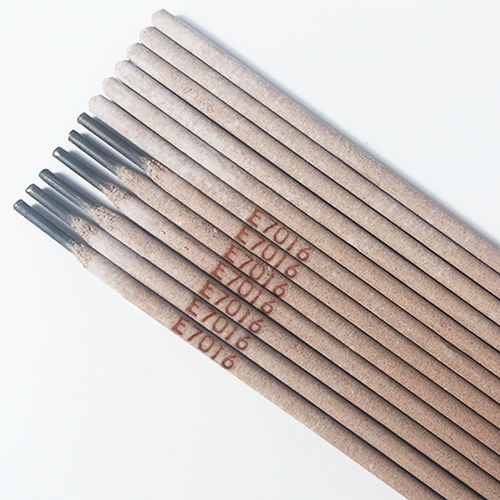

308l welding rod suppliers

2. Range of Options A good supplier will offer a wide variety of welding rods, including different diameters and lengths, catering to diverse welding needs. This flexibility allows welders to choose the most suitable product for their specific project.

3. Customer Service Reliable suppliers should provide exceptional customer service, offering technical support and guidance in selecting the right welding rod for particular applications. This assistance can be invaluable, especially for those new to welding.

4. Competitive Pricing Compare prices from different suppliers while considering the quality of their products. Affordable pricing paired with high-quality rods is essential for maximizing productivity and profitability.

5. Supply Chain Reliability Choose suppliers who have a reputation for timely deliveries. In a field where delays can cause significant project setbacks, ensuring a steady supply of welding rods is crucial.

6. Reputation and Reviews Researching a supplier's reputation through customer reviews and industry feedback can provide insights into their reliability and product quality. Suppliers with a good track record are more likely to be trustworthy.

Conclusion

The importance of 308L welding rods in the welding industry cannot be overstated. They play a vital role in ensuring the strength and durability of stainless steel constructions. As such, sourcing these rods from reputable suppliers is essential for welders to achieve the best results in their projects. By considering factors like product quality, customer service, and reliability, welders can find the right suppliers to meet their welding needs effectively. In the ever-evolving sectors of construction and manufacturing, having reliable materials and suppliers is key to success and innovation.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025