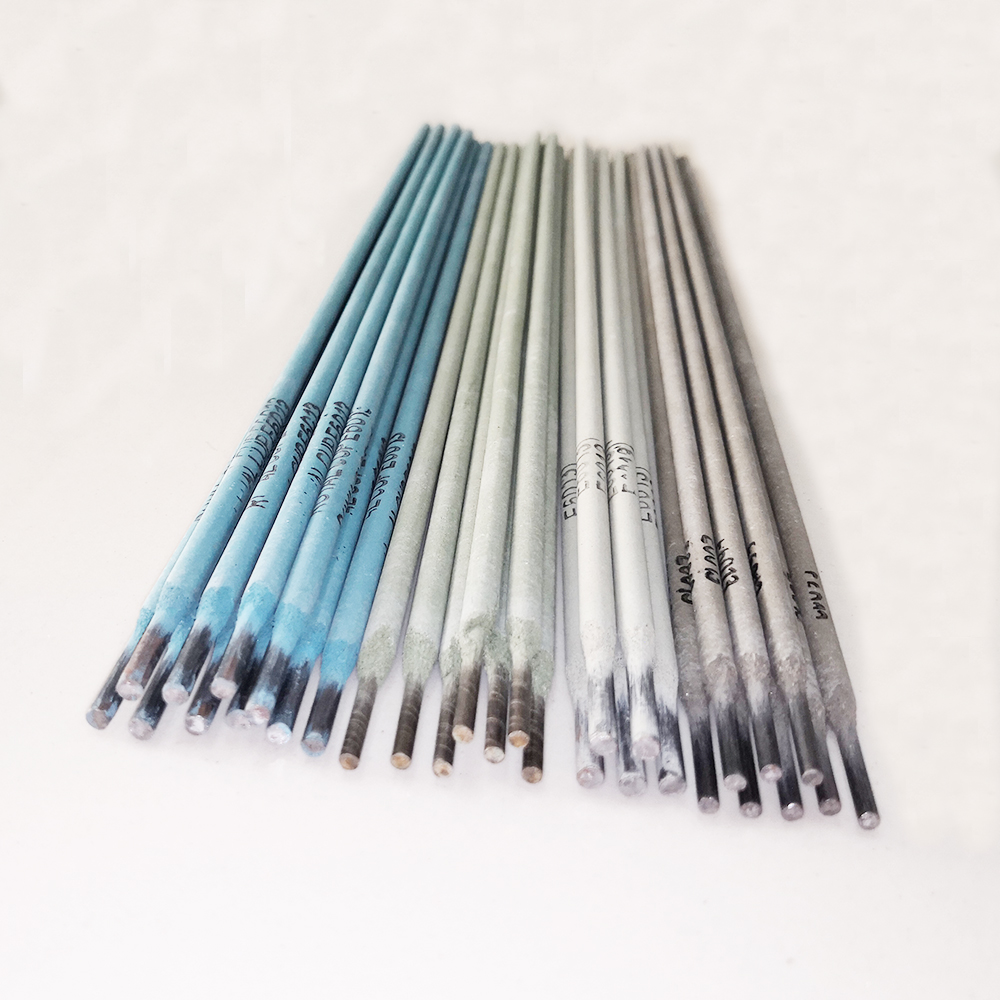

AWS E6013 Welding Electrodes – Smooth Arc, Low Spatter

Field Notes on E6013: What’s Behind the Everyday Electrode

If you work around mild steel, you’ve almost certainly struck an arc with [aws e6013 welding electrodes]. To be honest, this is the “daily driver” of stick rods—friendly arc, forgiving puddle, neat bead. Below, I’m unpacking specs, production flow, and some real-world feedback for the “China welding rod 6013 welding electrodes aws e6013” coming out of NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA.

Industry snapshot

E6013 remains a volume staple for light fabrication, maintenance, HVAC brackets, sheet-metal work, and training labs. Trends? Buyers are asking for cleaner slag peel and lower spatter, and—surprisingly—private-label packaging is hot for regional distributors. Prices have stabilized in 2025, while OEMs push tighter moisture controls to keep arc starts crisp in humid shops.

What it is (and why it’s easy to like)

aws e6013 welding electrodes are rutile-coated (high titanium dioxide), AC-friendly rods with smooth arc initiation and soft puddle control. This model aligns with AWS E6013 / GB E4303, using a high-titanium potassium coating—good for position work and thin-gage steel where you don’t want to blow through.

Product specs (typical)

| Standard / Classification | AWS A5.1 E6013; GB E4303; roughly ISO 2560-A E 38/42 RR |

| Coating type | Rutile (high-TiO2), potassium-activated, acidic flux |

| Diameters | 3.0–5.0 mm (common: 3.2, 4.0, 5.0 mm) |

| Recommended current (≈) | 3.2 mm: 90–130 A; 4.0 mm: 140–180 A; 5.0 mm: 180–220 A (AC/DC) |

| Mechanical properties (typ.) | UTS ≈ 420–520 MPa; YS ≈ 330–420 MPa; Elong. ≈ 20–28% (real-world use may vary) |

| Positions | All except vertical-down (best in flat/hor/vert-up/overhead) |

| Storage & re-bake | Store dry; recondition 110–150°C for 1–2 h if moisture pickup occurs |

How it’s made: a quick process flow

- Materials: Low-carbon steel core wire; rutile-rich flux (TiO2), potassium silicate binder, Fe powder, cellulose, deoxidizers.

- Method: Wire cleaning → flux mixing → extrusion coating → cut-to-length → printing → controlled baking → packaging.

- Testing: Coating concentricity and adhesion per AWS A5.1; moisture and diffusible hydrogen checks; bead appearance; tensile/bend coupon tests; lot traceability.

- Service life: Shelf stability 24–36 months in sealed cartons; performance depends on storage humidity.

- Certs/quality: Usually ISO 9001-managed; WPS/PQR conformity guided by AWS D1.1/ASME IX (project-dependent).

Applications and feedback

Use it for: light structural frames, gates, ducts, appliance brackets, vehicle body patches, farm repairs, ship outfit work, and shop training. Many customers say starts are “buttery,” slag peels in a ribbon, and the bead wets nicely around tacks. However, for thick single-pass joints or high-impact service, you may step up to 7018-class fillers.

Typical test snapshots

- Flat position fillet: smooth bead, minimal undercut, easy slag lift.

- Charpy (room temp, typical): ≈ 27–40 J, depending on heat input and procedure.

- Deposition rate: moderate; travel speed forgiving on thin sheet.

Vendor comparison (quick take)

| Vendor | Lead time (≈) | OEM/Private Label | Certs (typ.) | Notes |

|---|---|---|---|---|

| SteelToolsChina (origin: Shijiazhuang) | 2–4 weeks | Yes | ISO 9001 (factory); AWS conformance | Value pricing; diameters 3.0–5.0 mm |

| Global Brand A | Stock–2 weeks | Limited | Broad approvals | Premium price; tight QC |

| Local Trader B | 1–3 weeks | Sometimes | Varies by lot | Flexible MOQs; mixed sourcing |

Customization options

- Diameters and carton weights (e.g., 2.5–5.0 mm, 5–20 kg/carton).

- Flux tweaks for lower spatter or faster freezing puddle (project-specific).

- Brand print, color bands, multilingual cartons; barcoding and heat ID.

Case notes

- Ship repair yard: switched to aws e6013 welding electrodes for thin outfitting steel; reported 8–10% time savings from easier slag peel.

- Ag equipment shop: reduced burn-through on 2–3 mm panels by dialing 3.2 mm rods around 100 A AC—simple and effective.

- Tech college: standardized on E6013 for first-semester SMAW; cleaner learning curve before moving to 7018.

Final note: keep rods dry, don’t chase unrealistic amps, and let the flux do its job. It seems that’s half the battle with E6013.

Authoritative citations

- AWS A5.1/A5.1M: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding – American Welding Society. https://pubs.aws.org

- ISO 2560-A:2020, Welding consumables — Covered electrodes for manual metal arc welding of non-alloy and fine grain steels — Classification. https://www.iso.org/standard/70723.html

- AWS D1.1/D1.1M: Structural Welding Code — Steel. https://pubs.aws.org

- ASME Section IX: Welding, Brazing, and Fusing Qualifications. https://www.asme.org

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025