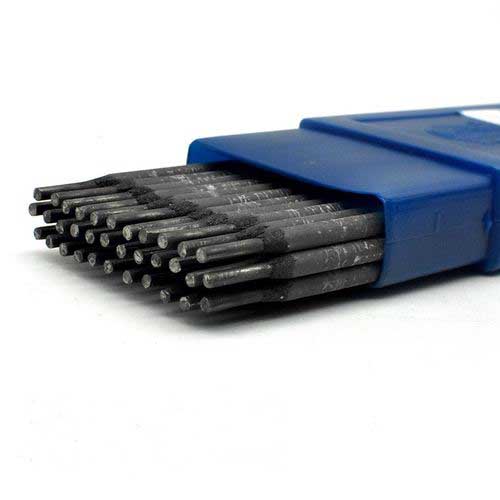

Cast Iron Welding Electrode Rod AWS ENiFe-CI: Strong, Reliable Repairs

Industry Trends in Cast Iron Welding Technology

The global industrial landscape is experiencing a significant shift towards sustainable repair and maintenance solutions, driving demand for advanced welding consumables. In the realm of ferrous metals, the challenge of welding cast iron, known for its brittleness and propensity for cracking due to thermal stress, has historically been a complex engineering task. However, advancements in metallurgy and electrode manufacturing have led to the development of highly specialized products like the Cast Iron Welding Electrode Rod AWS ENiFe-CI.

Current trends emphasize high-nickel and nickel-iron alloy electrodes, which offer superior ductility and crack resistance compared to their pure nickel counterparts, especially for high-strength cast irons. The market is increasingly demanding electrodes that provide not only strong, defect-free welds but also minimize pre-heating requirements and post-weld machining, leading to significant cost and time savings in repair operations across various heavy industries. Furthermore, environmental regulations are pushing manufacturers towards more efficient and less hazardous production processes, ensuring the electrodes themselves meet stringent quality and safety standards. The push for extended service life of critical components, rather than outright replacement, is a major driver for the adoption of premium welding solutions.

Detailed Process Flow: Manufacturing of Cast Iron Welding Electrode Rod AWS ENiFe-CI

The production of a high-performance Cast Iron Welding Electrode Rod AWS ENiFe-CI involves a meticulously controlled manufacturing process, ensuring metallurgical integrity and consistent performance. This process adheres strictly to international standards such as ISO 9001 for quality management and AWS A5.15 for specifications for welding electrodes for cast iron.

- Raw Material Procurement & Preparation:

- Core Wire: High-purity nickel-iron (NiFe) alloy wire forms the core. The precise ratio (typically 55% Nickel, 45% Iron, with minor elements like Manganese, Silicon, Carbon) is critical for achieving optimal weld metal properties, including ductility and resistance to hot cracking. This wire is drawn to specific diameters, typically through cold drawing processes, ensuring a uniform cross-section and mechanical properties.

- Flux Ingredients: A complex blend of mineral and chemical components constitutes the flux coating. These include arc stabilizers (e.g., calcium carbonate, rutile), slag formers (e.g., silicates), deoxidizers (e.g., ferrosilicon, ferromanganese), alloying elements (e.g., graphite, nickel powder), and binders (e.g., sodium silicate, potassium silicate). Each component is carefully weighed and mixed to a homogeneous paste.

- The core wire is fed into an extrusion press, where the flux paste is uniformly applied around it under high pressure. This process creates a consistent concentric coating. The thickness and uniformity of the flux coating are critical for arc stability, slag coverage, and overall weld quality.

- Immediately after extrusion, the electrodes are baked in specialized ovens at controlled temperatures. This process removes moisture from the flux coating, preventing hydrogen-induced cracking in the weld metal, a critical issue in cast iron welding. The baking temperature and duration are optimized to achieve the desired moisture content and coating strength.

- Each finished electrode is marked with its AWS classification (ENiFe-CI) and batch number for traceability. The striking end (arc initiation) and holding end are often prepared for optimal performance.

- Chemical Analysis: Spectrographic analysis of core wire and flux ingredients.

- Mechanical Testing: Weld metal deposited using the electrode is subjected to tensile strength, yield strength, and elongation tests according to ASTM/ISO standards.

- Radiographic & Dye Penetrant Testing: To ensure freedom from internal defects (porosity, inclusions) and surface cracks.

- Weldability Tests: Actual welding trials on cast iron plates to evaluate arc stability, slag detachability, bead appearance, and susceptibility to cracking.

- Electrodes are vacuum-packed or sealed in moisture-resistant container111s to maintain dryness and preserve performance until use.

Target Industries & Advantages:

- Petrochemical: Repair of cast iron pump casings, valve bodies, and compressor components exposed to corrosive environments. Advantages include corrosion resistance in mild chemical exposure and extended service life.

- Metallurgy: Restoration of heavy machinery, furnace parts, and rolling mill components. Energy saving through repair rather than replacement of expensive castings.

- Water Supply & Drainage: Repair of ductile iron pipes, fittings, and municipal pump stations. Offers robust, leak-free repairs crucial for infrastructure longevity.

- Automotive & Heavy Equipment: Repair of engine blocks, cylinder heads, gearboxes, and agricultural machinery. Minimizes downtime and cost of new parts.

Technical Specifications & Performance Parameters

The Cast Iron Welding Electrode Rod AWS ENiFe-CI is specifically engineered to address the unique challenges of welding various types of cast iron, including gray, malleable, and ductile cast iron. Its core composition of approximately 55% Nickel and 45% Iron provides a weld deposit that is highly resistant to cracking and offers excellent machinability. This specific alloy ratio provides a good balance between ductility (from nickel) and strength/cost-effectiveness (from iron). The flux coating is designed to produce a stable arc, minimize spatter, and ensure effective shielding, resulting in high-quality, porosity-free welds.

Typical Weld Metal Mechanical Properties (AWS A5.15 ENiFe-CI):

| Property | Metric Value | Imperial Value | Standard/Test Method |

|---|---|---|---|

| Tensile Strength (min) | 380 MPa | 55,000 psi | ASTM E8 / ISO 6892-1 |

| Yield Strength (min) | 280 MPa | 40,000 psi | ASTM E8 / ISO 6892-1 |

| Elongation (min) | 5% | 5% | ASTM E8 / ISO 6892-1 |

| Hardness (typical) | 180-220 HB | 180-220 HB | ASTM E10 / ISO 6506-1 |

Typical Weld Metal Chemical Composition (AWS A5.15 ENiFe-CI, wt.%):

| Element | Composition (wt.%) | Role/Impact |

|---|---|---|

| Nickel (Ni) | 50.0 - 60.0 | Enhances ductility, crack resistance, and machinability; lowers solidification temperature. |

| Iron (Fe) | Remainder | Base metal; contributes to strength and reduces overall cost compared to pure nickel. |

| Manganese (Mn) | 0.5 - 2.5 | Deoxidizer, desulfurizer; improves toughness and hot cracking resistance. |

| Silicon (Si) | 0.5 - 2.5 | Deoxidizer; promotes fluidity of the weld pool. |

| Carbon (C) | 1.0 - 2.5 | Graphitizer; contributes to machinability and compatibility with cast iron. |

Operating Characteristics:

- Polarity: DCEP (DC Electrode Positive) or AC. DCEP is generally preferred for smoother arc and deeper penetration.

- Arc Stability: Excellent, allowing for easy striking and consistent bead formation.

- Slag Removal: Easy to remove, self-peeling in many cases.

- Weld Bead Appearance: Smooth, finely rippled, with good wetting action.

- Typical Amperage Range: Varies by electrode diameter, e.g., 2.5mm (80-100A), 3.2mm (100-130A), 4.0mm (130-160A).

Application Scenarios & Technical Advantages

The versatility and superior performance of the Cast Iron Welding Electrode Rod AWS ENiFe-CI make it indispensable in a wide array of demanding industrial applications where the repair of cast iron components is crucial. From critical infrastructure to heavy manufacturing, its technical advantages offer tangible benefits over traditional repair methods.

Typical Application Scenarios:

- Automotive Repair: Repairing cracked engine blocks, cylinder heads, exhaust manifolds, and transmission housings in diesel trucks, heavy machinery, and vintage vehicles. The machinable weld deposit ensures components can be re-machined to original specifications.

- Heavy Machinery & Equipment: Welding broken gearboxes, pump casings, compressor bodies, agricultural machinery parts, and press frames. These repairs are critical for minimizing downtime and extending the operational life of expensive assets.

- Foundry & Pattern Shop: Correcting casting defects, repairing worn patterns, and restoring molds.

- General Maintenance & Fabrication: Joining dissimilar metals (e.g., cast iron to steel), building up worn surfaces, and performing general maintenance repairs on cast iron structures.

Key Technical Advantages:

- Superior Crack Resistance: The high nickel-iron core minimizes dilution with the base metal and produces a ductile weld deposit, significantly reducing the risk of cracking, especially in highly stressed or pre-stressed components. This is crucial for maintaining structural integrity in dynamic load applications.

- Excellent Machinability: The weld metal is readily machinable, allowing for subsequent finishing operations such as drilling, tapping, and grinding, which is often a critical requirement for repairing precision components. This prevents hard spots that can damage cutting tools.

- Low Heat Input Capability: Can be used with minimal or no pre-heating in many applications, reducing the overall thermal stress on the cast iron and simplifying the welding procedure. This contributes to energy saving and improved efficiency.

- Strong, Porosity-Free Welds: The specialized flux coating provides excellent shielding and deoxidizing action, ensuring a clean, strong, and defect-free weld metal deposit with minimal porosity and slag inclusions.

- Versatility: Effective for welding various types of cast iron, including gray, malleable, and nodular (ductile) cast iron, and for joining cast iron to mild steel.

- Corrosion Resistance: The nickel-iron alloy weld deposit offers enhanced resistance to certain corrosive agents, extending the service life of repaired components in demanding environments.

Vendor Comparison: Choosing Your Supplier

When sourcing Cast Iron Welding Electrode Rod AWS ENiFe-CI, discerning buyers must look beyond mere pricing to evaluate a vendor's commitment to quality, technical support, and consistent supply. Key differentiators include adherence to international standards, comprehensive testing protocols, and the ability to provide tailored solutions.

Comparison Factors for ENiFe-CI Electrodes:

| Feature | High-Quality Supplier (e.g., Steel Tools China) | Standard Supplier |

|---|---|---|

| AWS Classification Adherence | Strictly adheres to AWS A5.15 ENiFe-CI; certified by independent labs. | May meet basic requirements, less stringent testing. |

| Raw Material Purity | Utilizes high-purity nickel and iron alloys; traceable sources. | Standard industrial grade materials, potential for impurities affecting weld. |

| Weldability & Arc Stability | Superior arc stability, minimal spatter, excellent bead shape across AC/DC. | Variable arc, more spatter, inconsistent bead. |

| Weld Metal Machinability | Consistently soft and easily machinable weld deposit. | May produce hard spots, leading to difficulties in post-weld machining. |

| Crack Resistance | High resistance to hot and cold cracking due to optimized metallurgy. | Higher susceptibility to cracking, especially on difficult castings. |

| Certifications & QMS | ISO 9001 certified, comprehensive batch testing and certification. | Basic quality checks, fewer external certifications. |

| Technical Support | Dedicated technical team, application engineers, tailored advice. | Limited technical assistance, primarily sales-focused. |

Choosing a reputable vendor with proven expertise, such as Steel Tools China with its commitment to ISO standards and rigorous quality control, ensures that the Cast Iron Welding Electrode Rod AWS ENiFe-CI you receive will consistently meet or exceed performance expectations, translating into reliable repairs and reduced operational risks.

Customized Solutions & Application Case Studies

While standard Cast Iron Welding Electrode Rod AWS ENiFe-CI rods provide excellent performance for most applications, some specialized industrial requirements may necessitate customized solutions. Leading manufacturers understand that specific casting compositions, extreme service environments, or unique joint designs might benefit from tailored electrode formulations or packaging.

Customization Capabilities:

- Specialized Formulations: Adjustments to flux composition for enhanced mechanical properties, specific corrosion resistance, or improved weldability on unusual cast iron alloys (e.g., high-chromium cast irons).

- Diameter & Length Variations: Production of electrodes in non-standard diameters or lengths to suit particular welding equipment or confined access conditions.

- Packaging Solutions: Bulk packaging, specific branding, or advanced moisture-barrier packaging for extended shelf life in harsh environments.

- Certification & Testing: Provision of specific third-party certifications or additional destructive/non-destructive testing as required by project specifications (e.g., FDA compliance for certain food processing equipment repairs, or specific marine certifications).

Application Case Studies:

Case Study 1: Large Industrial Pump Casing Repair

A major chemical plant experienced a critical failure in a large cast iron pump casing, leading to significant production downtime. The casing, weighing over 500 kg, had a 30 cm long crack through a critical section. Replacing the unit would have cost over $80,000 and taken 6-8 weeks. Using Cast Iron Welding Electrode Rod AWS ENiFe-CI (3.2mm and 4.0mm), welders prepped the crack with a grinding wheel and used a stringer bead technique with minimal pre-heating (around 150°C) to control thermal stresses. Post-weld, the section was visually inspected and dye penetrant tested, showing a defect-free repair. The pump was back in service within 48 hours, saving the plant substantial costs and avoiding extended downtime. The weld deposit's excellent machinability allowed for precision grinding to restore the original pump clearances.

Case Study 2: Vintage Engine Block Restoration

An automotive restoration workshop was tasked with repairing a severely cracked engine block from a rare vintage car. The challenge lay in the thin sections of the block and the need for a highly machinable weld that would not create hard spots, which could damage boring tools during engine rebuild. After careful chamfering and cleaning, Cast Iron Welding Electrode Rod AWS ENiFe-CI (2.5mm) was chosen. A "cold welding" technique with short, intermittent beads and peening was employed to minimize heat input. The resulting repair was structurally sound, showed no signs of cracking, and most importantly, was uniformly machinable, allowing the block to be rebored and honed to original specifications, preserving the authenticity and value of the vehicle.

Frequently Asked Questions (FAQ)

Q: What types of cast iron can be welded with ENiFe-CI electrodes?

A: The Cast Iron Welding Electrode Rod AWS ENiFe-CI is highly versatile and suitable for welding gray cast iron, malleable cast iron, and nodular (ductile) cast iron. It is also effective for joining cast iron to mild steel.

Q: Is pre-heating required when using these electrodes?

A: While some pre-heating (100-200°C / 200-400°F) is often recommended for larger or more complex cast iron components to mitigate thermal stress, ENiFe-CI electrodes can frequently be used with minimal or even no pre-heating on smaller, less critical repairs, especially when employing the "cold welding" technique (short beads, peening).

Q: What is the primary difference between ENi-CI and ENiFe-CI electrodes?

A: ENi-CI electrodes are pure nickel, offering maximum ductility and machinability. ENiFe-CI electrodes contain approximately 55% nickel and 45% iron. While still providing excellent machinability and crack resistance, the iron content in Cast Iron Welding Electrode Rod AWS ENiFe-CI makes them more cost-effective and provides higher strength, making them ideal for high-strength cast irons or where cost is a significant factor.

Lead Time, Warranty & Customer Support

We understand the critical importance of timely delivery and reliable support for industrial operations. Our commitment extends beyond product quality to ensuring a seamless customer experience.

Lead Time & Fulfillment:

- Standard Orders: For in-stock items, lead times typically range from 3-7 business days for domestic shipments and 7-21 days for international orders, depending on destination and shipping method.

- Bulk & Custom Orders: Specific lead times will be provided upon quotation, tailored to the complexity and volume of the order. We maintain robust inventory levels and efficient production schedules to minimize delays.

- Expedited Shipping: Expedited shipping options are available for urgent requirements; please contact our sales team for details and pricing.

Warranty Commitments:

- We provide a standard 12-month warranty on all Cast Iron Welding Electrode Rod AWS ENiFe-CI products from the date of purchase, guaranteeing against manufacturing defects and material non-conformity to AWS A5.15 standards.

- This warranty covers material integrity and performance under normal storage and use conditions as per product specifications. It does not cover misuse, improper storage leading to moisture absorption, or application in unsuitable conditions.

Customer Support:

- Technical Assistance: Our team of experienced welding engineers and technical specialists is available to provide expert advice on product selection, welding procedures, and troubleshooting.

- Sales & Order Support: Dedicated account managers are on hand to assist with inquiries, quotations, order placement, and tracking.

-

Contact Information:

- Email: sales@steeltoolschina.com

- Phone: +86-XXX-XXXX-XXXX (example)

- Website: www.steeltoolschina.com

- Commitment: We are committed to fostering long-term partnerships built on trust, quality, and unparalleled support.

References:

- American Welding Society. AWS A5.15/A5.15M:2009. Specification for Welding Electrodes and Rods for Cast Iron. Miami, FL: American Welding Society.

- ISO 9001:2015. Quality management systems – Requirements. International Organization for Standardization.

- ASM Handbook, Vol. 6: Welding, Brazing, and Soldering. ASM International.

- Metals Handbook, Desk Edition. ASM International.

- Gourd, L. M. (1995). Principles of Welding Technology. Edward Arnold.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025