High-Quality Carbon Steel Welding Wire for Strong, Reliable Joins

Understanding the Modern Landscape of carbon steel welding wire

In the demanding world of fabrication and industrial construction, the integrity of welded joints is paramount. At the core of this reliability lies the quality of welding consumables, particularly carbon steel welding wire. This comprehensive guide delves into the critical aspects of copper coated welding wire for carbon steel, a staple in countless manufacturing and construction processes. We aim to provide B2B decision-makers and technical engineers with an in-depth understanding of industry trends, technical specifications, application advantages, and crucial considerations for procurement and implementation.

The choice of welding wire directly impacts productivity, cost-efficiency, and, most critically, the structural integrity and longevity of welded components. As industries evolve, so do the demands on welding consumables, pushing for greater performance, consistency, and compliance with stringent international standards. Our discussion will highlight how advanced manufacturing processes and stringent quality control ensure that our products, such as our premium copper coated welding wire, meet and exceed these expectations.

Industry Trends and Market Dynamics

The global market for carbon steel welding wire is characterized by a drive towards higher efficiency, improved weld quality, and enhanced automation. Key trends include:

- Automation Integration: With the rise of robotic welding, there is an increasing demand for welding wires that offer consistent feedability, minimal spatter, and stable arc characteristics, optimizing automated production lines.

- High-Strength and Specialized Alloys: While carbon steel remains prevalent, the demand for welding wires compatible with higher-strength low-alloy steels (HSLA) is growing, necessitating precise chemical compositions and mechanical properties.

- Environmental & Safety Regulations: Stricter environmental policies are encouraging the development of welding wires with lower fume emissions and reduced hazardous material content. The industry is also seeing a shift towards copper-free wires, though copper-coated wires remain a robust, cost-effective standard.

- Digitalization & Data Analytics: Manufacturers are leveraging data from welding processes to refine wire formulations and production, leading to more predictable performance and quality control.

According to market research from Mordor Intelligence, the welding consumables market is projected to grow significantly, driven by increasing infrastructure development and manufacturing activities globally. The Asia-Pacific region, particularly China, continues to dominate consumption and production, owing to its robust automotive, construction, and heavy engineering sectors. This growth underscores the enduring importance and continuous evolution of products like carbon steel welding wire in the global industrial landscape.

Detailed Manufacturing Process Flow of Carbon Steel Welding Wire

The production of high-quality carbon steel welding wire, specifically our Copper Coated Welding Wire for carbon steel, involves a meticulously controlled, multi-stage process designed to ensure superior metallurgical properties and consistent performance. This process ensures the wire meets stringent international testing standards such as ISO 9001, AWS A5.18, and JIS Z 3312.

Process Steps:

- Raw Material Selection (Steel Rod Coil): High-purity low-carbon steel rod coils are selected as the base material. The chemical composition is rigorously tested to ensure optimal levels of carbon, manganese, silicon, and other trace elements. This foundational step is critical for achieving desired tensile strength and ductility in the final weld.

- Surface Preparation & Descaling: The steel rod coils undergo mechanical descaling (shot blasting) and chemical cleaning (acid pickling) to remove mill scale, rust, and surface impurities. This creates a clean surface essential for subsequent drawing and coating processes, preventing defects in the final wire.

- Primary Drawing: The descaled rod is drawn through a series of dies, gradually reducing its diameter. This cold working process refines the grain structure and increases the material's tensile strength. Proper lubrication is vital to minimize friction and heat.

- Intermediate Annealing (Optional, based on desired properties): For certain wire types or to restore ductility after significant cold work, the wire may undergo intermediate annealing. This heat treatment process alters the microstructure, making the wire more pliable for further drawing.

- Secondary Drawing & Final Sizing: The wire continues through additional drawing stages until it reaches its final desired diameter (e.g., 0.8mm, 1.0mm, 1.2mm). Precise die selection and control are paramount at this stage to achieve accurate sizing and a smooth surface finish.

- Copper Coating Application: The drawn wire passes through an electrolytic copper plating bath. This process applies a uniform, thin layer of copper onto the steel surface. The copper coating serves multiple critical functions: it enhances electrical conductivity for stable arc starts, reduces contact tip wear, prevents rust and corrosion of the wire, and improves feedability through welding gun liners.

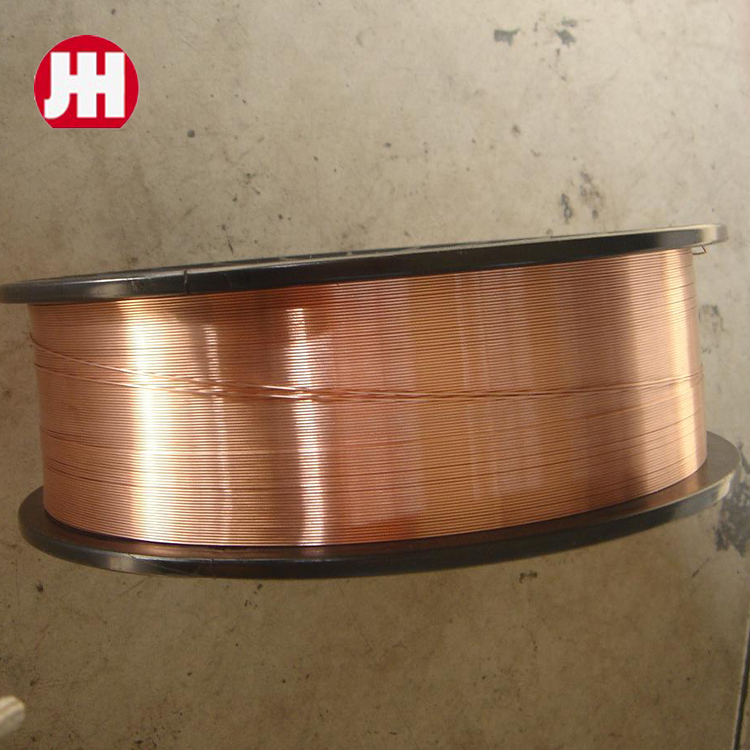

- Lubrication and Spooling: A final layer of lubricant is applied to the copper-coated wire to ensure smooth feeding characteristics during welding. The wire is then precision-wound onto various spool sizes (e.g., 5kg, 15kg, 20kg) using automated spooling machines, ensuring tangle-free unwinding.

- Quality Control & Testing: Throughout and after the manufacturing process, rigorous quality control checks are performed. This includes:

- Chemical Analysis: Verification of raw material and finished wire composition.

- Mechanical Testing: Tensile strength, yield strength, elongation, and impact toughness (Charpy V-notch) tests on weld metal deposited using the wire.

- Dimensional Accuracy: Verification of wire diameter and spool winding quality.

- Surface Quality: Inspection for defects, uniform copper coating, and rust resistance.

- Welding Performance Tests: Actual welding trials to assess arc stability, spatter levels, bead appearance, and penetration.

- Packaging and Dispatch: Finished spools are securely packaged, often with desiccant, to protect against moisture and physical damage during transit and storage. Each package is labeled with relevant product information and certifications.

Our carbon steel welding wire is designed for a service life that aligns with the lifespan of the structures it helps create, often decades, provided it is used and stored according to industry best practices. Target industries include petrochemical, metallurgy, shipbuilding, automotive, heavy machinery, and water supply & drainage. The advantages in typical application scenarios include enhanced energy saving through stable arc performance, superior corrosion resistance due to the copper coating, and excellent mechanical properties of the deposited weld metal.

Technical Specifications and Performance Parameters

Our copper coated carbon steel welding wire, suitable for both MIG/MAG (GMAW) and TIG (GTAW) applications (when supplied as a cut rod), is engineered to deliver consistent, high-quality results. The technical specifications below highlight key parameters critical for engineers and procurement specialists.

Typical Product Specifications (AWS A5.18 ER70S-6 Equivalent)

| Parameter | Value/Range | Unit |

|---|---|---|

| Tensile Strength | ≥ 550 | MPa |

| Yield Strength | ≥ 460 | MPa |

| Elongation | ≥ 22 | % |

| Charpy V-notch Impact (at -30°C) | ≥ 47 | J |

| Wire Diameter Range | 0.8 - 1.6 | mm |

| Typical Chemical Composition (wt%) | C: 0.06-0.15, Si: 0.8-1.15, Mn: 1.4-1.85, P: ≤0.025, S: ≤0.035, Cu: ≤0.50 (coating) | % |

| Shielding Gas (MIG/MAG) | CO2, Ar/CO2 Mix | - |

Our carbon steel mig wire offers excellent arc stability and low spatter, contributing to clean welds and reduced post-weld cleanup. For precision applications, our carbon steel tig rod provides superior control and aesthetics, crucial for critical joints where visual quality is as important as mechanical strength. These parameters ensure compatibility with a wide range of mild and low-alloy steels, meeting requirements for demanding structural and fabrication projects.

Application Scenarios and Technical Advantages

The versatility and robust performance of our copper coated carbon steel welding wire make it indispensable across a multitude of industries and applications:

- Automotive Manufacturing: Used extensively in chassis assembly, exhaust systems, and body panel fabrication due to its excellent weldability and consistency, supporting high-volume production lines.

- Construction & Infrastructure: From structural steel frameworks in buildings and bridges to pipeline construction and heavy equipment repair, our wire provides reliable, strong joints capable of withstanding significant loads and environmental stresses.

- Shipbuilding: Essential for fabricating hull structures, deck components, and internal fittings, where welds must endure corrosive marine environments and dynamic stresses.

- Pressure Vessels & Boilers: Critical for high-integrity joints in pressure-retaining components, demanding precise control over weld metallurgy and defect-free deposition.

- General Fabrication & Manufacturing: Ideal for general workshop use, producing machinery parts, agricultural equipment, and various metal products.

Key Technical Advantages:

- Superior Arc Stability & Reduced Spatter: The consistent copper coating and precise wire chemistry ensure a smooth, stable arc, minimizing spatter and reducing post-weld cleaning, thereby increasing productivity.

- Excellent Feedability: The smooth, copper-coated surface significantly reduces friction in the welding gun liner, ensuring consistent wire feeding, especially critical for automated and robotic welding systems.

- Enhanced Corrosion Resistance: The copper layer acts as a barrier, protecting the steel core from atmospheric corrosion during storage and handling, extending shelf life and preventing feeding issues caused by rust.

- High Mechanical Properties: Welds produced with our wire exhibit excellent tensile strength, yield strength, and impact toughness, ensuring durable and reliable joints that meet or exceed industry standards.

- Versatile Shielding Gas Compatibility: Optimized for use with both 100% CO2 and Argon/CO2 mixed gases, offering flexibility for various welding applications and operational preferences.

- Consistent Quality: Manufactured under strict ISO 9001 quality management systems, each batch undergoes rigorous testing to guarantee uniformity in chemical composition, mechanical properties, and physical dimensions.

Vendor Comparison: Why Choose Our Copper Coated Welding Wire

In a competitive market, selecting the right supplier for carbon steel welding wire is crucial. Our commitment to quality, innovation, and customer satisfaction sets us apart. Below is a comparative overview highlighting our strengths:

Product & Service Comparison Table

| Feature/Criterion | Our Product/Service | Typical Competitor |

|---|---|---|

| Arc Stability (Robotic/Automated Welding) | Exceptional; minimal fluctuations, ideal for high-speed automation. | Good; may show minor fluctuations, potentially impacting automated consistency. |

| Spatter Level | Very Low; significantly reduces post-weld cleanup time and costs. | Moderate; requires more post-weld cleanup, increasing labor. |

| Wire Feedability | Superior; uniform copper coating and precise winding prevent tangles and jams. | Standard; occasional feeding issues, especially with longer conduits. |

| Copper Coating Uniformity & Adhesion | Excellent; consistent thickness ensures optimal electrical contact and corrosion protection. | Variable; thinner or inconsistent coating can lead to rust and contact issues. |

| Certifications & Compliance | ISO 9001, AWS A5.18, JIS Z 3312, CE; full traceability. | Often meets basic national standards, may lack broader international recognition. |

| Technical Support | Dedicated engineering support, application guidance, and troubleshooting. | Standard customer service; limited deep technical expertise. |

| Customization Options | Flexible for specific diameters, packaging, and chemical compositions. | Generally limited to standard product lines. |

Our company has over 15 years of experience in the manufacturing and supply of welding consumables, building a reputation for reliability and technical excellence. Our robust quality assurance, evidenced by our ISO certifications, ensures every product adheres to the highest standards. We also partner with leading logistics providers to ensure efficient and timely delivery to our global client base.

Customized Solutions and Application Case Studies

Recognizing that standard products may not always meet every unique project requirement, we offer comprehensive customized solutions for our carbon steel welding wire. This flexibility extends to specific wire diameters, precise chemical compositions for particular steel grades, and specialized packaging formats to integrate seamlessly into diverse production environments. Our R&D team works closely with clients to develop tailored solutions, ensuring optimal performance for highly specialized applications.

Application Case Study 1: Large-Scale Pipeline Construction

Client: A leading international energy infrastructure company.

Challenge: The client required a high-performance carbon steel mig wire for automated multi-pass welding of large-diameter oil and gas pipelines. Key challenges included maintaining consistent weld quality in varying environmental conditions (field welding), minimizing spatter to reduce grinding time, and achieving high deposition rates to meet aggressive project timelines.

Solution: We supplied our specialized copper coated carbon steel mig wire (AWS A5.18 ER70S-6 equivalent, 1.2mm diameter) known for its excellent arc stability in spray and pulsed spray transfer modes. Our wire's consistent feedability and low spatter characteristics were crucial for the client's automated welding rigs. We also provided on-site technical support to optimize welding parameters and address any challenges.

Result: The client reported a 15% increase in welding speed due to higher deposition rates and reduced post-weld cleanup, significantly accelerating project completion. Weld integrity tests consistently showed superior mechanical properties and minimal defects, leading to substantial cost savings and enhanced structural reliability of the pipelines. This project validated the wire's performance under rigorous field conditions and its contribution to energy-saving through efficient welding.

Application Case Study 2: Precision Fabrication for Heavy Machinery

Client: A prominent manufacturer of excavators and heavy construction equipment.

Challenge: The client needed a reliable carbon steel tig rod for critical structural components, where weld quality, aesthetics, and fatigue resistance were paramount. The welding involved complex geometries and demanding stress conditions, requiring a wire that offered exceptional control, minimal porosity, and clean, defect-free beads.

Solution: We supplied our precision-cut carbon steel tig rod (AWS A5.18 ER70S-2 equivalent), specifically formulated for TIG welding mild and low-alloy steels. Our rods are known for their cleanliness, excellent puddle control, and consistent melting characteristics, which are vital for intricate, high-quality TIG welds.

Result: The manufacturer achieved consistently high-quality welds, meeting stringent fatigue life requirements for heavy machinery. The superior aesthetic quality of the welds also reduced the need for post-weld grinding and finishing, saving labor costs. Customer feedback highlighted the exceptional ease of use and the significant reduction in weld defects, improving overall product quality and reliability for their heavy equipment.

Frequently Asked Questions (FAQ)

- Q1: What is the primary advantage of copper coating on carbon steel welding wire?

- A1: The copper coating primarily provides enhanced electrical conductivity for stable arc starts, reduces contact tip wear, protects the wire from rust and corrosion during storage, and significantly improves wire feedability by reducing friction in the welding gun liner. These factors collectively contribute to more consistent and higher-quality welds.

- Q2: Can this carbon steel welding wire be used for both MIG/MAG and TIG welding?

- A2: Our copper coated welding wire is primarily designed as a continuous wire for MIG/MAG (GMAW) processes. However, a similar formulation of carbon steel tig rod (cut lengths) is available for TIG (GTAW) applications where precise control and high-quality, aesthetically pleasing welds are required. Please specify your process when inquiring.

- Q3: What shielding gases are recommended for your carbon steel welding wire?

- A3: For MIG/MAG welding, 100% CO2 is commonly used, especially for deeper penetration and cost-effectiveness. Alternatively, an Argon/CO2 mixed gas (e.g., 75% Ar / 25% CO2) is highly recommended for improved arc stability, reduced spatter, and better bead appearance, particularly in automated or robotic applications.

- Q4: What is the typical lead time for large orders?

- A4: Our standard lead time for regular stock items and moderate order volumes is typically 2-4 weeks. For larger, customized orders or specific chemical compositions, the lead time may extend to 4-8 weeks, depending on the complexity and volume. We recommend discussing your specific project timeline with our sales team for an accurate estimate.

Lead Time, Warranty, and Customer Support

Lead Time & Fulfillment

We prioritize efficient order fulfillment to support your production schedules. Our state-of-the-art manufacturing facilities and robust supply chain management enable us to maintain competitive lead times. For standard specifications of copper coated carbon steel welding wire, orders are typically processed and ready for dispatch within 2-4 weeks. Expedited options are available for urgent requirements, subject to production capacity and material availability. We work with trusted global logistics partners to ensure timely and secure delivery to your specified location, complete with tracking and comprehensive documentation.

Warranty Commitments

We stand behind the quality of our products. Our copper coated welding wire for carbon steel comes with a manufacturer's warranty against defects in material and workmanship for a period of 12 months from the date of purchase, provided the product is stored and used in accordance with our recommendations and industry best practices. This warranty covers the wire's chemical composition, mechanical properties, and physical characteristics as per the stated specifications and applicable international standards (e.g., AWS, ISO). Any claims are subject to inspection and verification by our quality assurance team.

Customer Support & After-Sales Service

Our commitment to our clients extends beyond delivery. We offer comprehensive after-sales support, including technical assistance, application guidance, and troubleshooting. Our team of experienced welding engineers is available to provide expert advice on welding parameters, material compatibility, and process optimization to ensure you achieve the best possible results with our products. We also provide full traceability for all our products, ensuring that you have access to detailed batch information and quality certifications whenever needed. For any inquiries or support, please contact us via the details provided on our website: www.steeltoolschina.com.

Conclusion

The selection of welding consumables is a strategic decision that directly impacts operational efficiency, product quality, and long-term cost-effectiveness. Our copper coated carbon steel welding wire is engineered to meet the stringent demands of modern B2B applications, offering a blend of superior performance, consistency, and reliability. By adhering to rigorous manufacturing processes, embracing international quality standards, and providing dedicated customer support, we ensure that our products empower our clients to achieve exceptional welding outcomes across diverse industrial sectors. Partner with us for a dependable supply of high-quality welding solutions that drive productivity and excellence.

References

- American Welding Society. (2010). AWS A5.18/A5.18M: Specification for Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding. Miami, FL: AWS.

- International Organization for Standardization. (2015). ISO 9001: Quality management systems – Requirements. Geneva, Switzerland: ISO.

- Mordor Intelligence. (2023). Welding Consumables Market - Growth, Trends, COVID-19 Impact, and Forecasts (2023 - 2028). Retrieved from Mordor Intelligence website.

- The Welding Institute. (2022). Guidance for selecting MIG/MAG welding wire. Retrieved from TWI Ltd. website.

- Journal of Manufacturing Processes. (2021). Advances in Arc Welding Technologies for Enhanced Productivity and Quality. Elsevier.

-

What is a medium-frequency pulse? What types of welding are suitable for?NewsNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NewsNov.21,2025

-

Welding Knowledge 6NewsNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NewsNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NewsNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NewsNov.17,2025

High-Quality Carbon Steel Welding Wire for Strong, Reliable Joins

Understanding the Modern Landscape of carbon steel welding wire

In the demanding world of fabrication and industrial construction, the integrity of welded joints is paramount. At the core of this reliability lies the quality of welding consumables, particularly carbon steel welding wire. This comprehensive guide delves into the critical aspects of copper coated welding wire for carbon steel, a staple in countless manufacturing and construction processes. We aim to provide B2B decision-makers and technical engineers with an in-depth understanding of industry trends, technical specifications, application advantages, and crucial considerations for procurement and implementation.

The choice of welding wire directly impacts productivity, cost-efficiency, and, most critically, the structural integrity and longevity of welded components. As industries evolve, so do the demands on welding consumables, pushing for greater performance, consistency, and compliance with stringent international standards. Our discussion will highlight how advanced manufacturing processes and stringent quality control ensure that our products, such as our premium copper coated welding wire, meet and exceed these expectations.

Industry Trends and Market Dynamics

The global market for carbon steel welding wire is characterized by a drive towards higher efficiency, improved weld quality, and enhanced automation. Key trends include:

- Automation Integration: With the rise of robotic welding, there is an increasing demand for welding wires that offer consistent feedability, minimal spatter, and stable arc characteristics, optimizing automated production lines.

- High-Strength and Specialized Alloys: While carbon steel remains prevalent, the demand for welding wires compatible with higher-strength low-alloy steels (HSLA) is growing, necessitating precise chemical compositions and mechanical properties.

- Environmental & Safety Regulations: Stricter environmental policies are encouraging the development of welding wires with lower fume emissions and reduced hazardous material content. The industry is also seeing a shift towards copper-free wires, though copper-coated wires remain a robust, cost-effective standard.

- Digitalization & Data Analytics: Manufacturers are leveraging data from welding processes to refine wire formulations and production, leading to more predictable performance and quality control.

According to market research from Mordor Intelligence, the welding consumables market is projected to grow significantly, driven by increasing infrastructure development and manufacturing activities globally. The Asia-Pacific region, particularly China, continues to dominate consumption and production, owing to its robust automotive, construction, and heavy engineering sectors. This growth underscores the enduring importance and continuous evolution of products like carbon steel welding wire in the global industrial landscape.

Detailed Manufacturing Process Flow of Carbon Steel Welding Wire

The production of high-quality carbon steel welding wire, specifically our Copper Coated Welding Wire for carbon steel, involves a meticulously controlled, multi-stage process designed to ensure superior metallurgical properties and consistent performance. This process ensures the wire meets stringent international testing standards such as ISO 9001, AWS A5.18, and JIS Z 3312.

Process Steps:

- Raw Material Selection (Steel Rod Coil): High-purity low-carbon steel rod coils are selected as the base material. The chemical composition is rigorously tested to ensure optimal levels of carbon, manganese, silicon, and other trace elements. This foundational step is critical for achieving desired tensile strength and ductility in the final weld.

- Surface Preparation & Descaling: The steel rod coils undergo mechanical descaling (shot blasting) and chemical cleaning (acid pickling) to remove mill scale, rust, and surface impurities. This creates a clean surface essential for subsequent drawing and coating processes, preventing defects in the final wire.

- Primary Drawing: The descaled rod is drawn through a series of dies, gradually reducing its diameter. This cold working process refines the grain structure and increases the material's tensile strength. Proper lubrication is vital to minimize friction and heat.

- Intermediate Annealing (Optional, based on desired properties): For certain wire types or to restore ductility after significant cold work, the wire may undergo intermediate annealing. This heat treatment process alters the microstructure, making the wire more pliable for further drawing.

- Secondary Drawing & Final Sizing: The wire continues through additional drawing stages until it reaches its final desired diameter (e.g., 0.8mm, 1.0mm, 1.2mm). Precise die selection and control are paramount at this stage to achieve accurate sizing and a smooth surface finish.

- Copper Coating Application: The drawn wire passes through an electrolytic copper plating bath. This process applies a uniform, thin layer of copper onto the steel surface. The copper coating serves multiple critical functions: it enhances electrical conductivity for stable arc starts, reduces contact tip wear, prevents rust and corrosion of the wire, and improves feedability through welding gun liners.

- Lubrication and Spooling: A final layer of lubricant is applied to the copper-coated wire to ensure smooth feeding characteristics during welding. The wire is then precision-wound onto various spool sizes (e.g., 5kg, 15kg, 20kg) using automated spooling machines, ensuring tangle-free unwinding.

- Quality Control & Testing: Throughout and after the manufacturing process, rigorous quality control checks are performed. This includes:

- Chemical Analysis: Verification of raw material and finished wire composition.

- Mechanical Testing: Tensile strength, yield strength, elongation, and impact toughness (Charpy V-notch) tests on weld metal deposited using the wire.

- Dimensional Accuracy: Verification of wire diameter and spool winding quality.

- Surface Quality: Inspection for defects, uniform copper coating, and rust resistance.

- Welding Performance Tests: Actual welding trials to assess arc stability, spatter levels, bead appearance, and penetration.

- Packaging and Dispatch: Finished spools are securely packaged, often with desiccant, to protect against moisture and physical damage during transit and storage. Each package is labeled with relevant product information and certifications.

Our carbon steel welding wire is designed for a service life that aligns with the lifespan of the structures it helps create, often decades, provided it is used and stored according to industry best practices. Target industries include petrochemical, metallurgy, shipbuilding, automotive, heavy machinery, and water supply & drainage. The advantages in typical application scenarios include enhanced energy saving through stable arc performance, superior corrosion resistance due to the copper coating, and excellent mechanical properties of the deposited weld metal.

Technical Specifications and Performance Parameters

Our copper coated carbon steel welding wire, suitable for both MIG/MAG (GMAW) and TIG (GTAW) applications (when supplied as a cut rod), is engineered to deliver consistent, high-quality results. The technical specifications below highlight key parameters critical for engineers and procurement specialists.

Typical Product Specifications (AWS A5.18 ER70S-6 Equivalent)

| Parameter | Value/Range | Unit |

|---|---|---|

| Tensile Strength | ≥ 550 | MPa |

| Yield Strength | ≥ 460 | MPa |

| Elongation | ≥ 22 | % |

| Charpy V-notch Impact (at -30°C) | ≥ 47 | J |

| Wire Diameter Range | 0.8 - 1.6 | mm |

| Typical Chemical Composition (wt%) | C: 0.06-0.15, Si: 0.8-1.15, Mn: 1.4-1.85, P: ≤0.025, S: ≤0.035, Cu: ≤0.50 (coating) | % |

| Shielding Gas (MIG/MAG) | CO2, Ar/CO2 Mix | - |

Our carbon steel mig wire offers excellent arc stability and low spatter, contributing to clean welds and reduced post-weld cleanup. For precision applications, our carbon steel tig rod provides superior control and aesthetics, crucial for critical joints where visual quality is as important as mechanical strength. These parameters ensure compatibility with a wide range of mild and low-alloy steels, meeting requirements for demanding structural and fabrication projects.

Application Scenarios and Technical Advantages

The versatility and robust performance of our copper coated carbon steel welding wire make it indispensable across a multitude of industries and applications:

- Automotive Manufacturing: Used extensively in chassis assembly, exhaust systems, and body panel fabrication due to its excellent weldability and consistency, supporting high-volume production lines.

- Construction & Infrastructure: From structural steel frameworks in buildings and bridges to pipeline construction and heavy equipment repair, our wire provides reliable, strong joints capable of withstanding significant loads and environmental stresses.

- Shipbuilding: Essential for fabricating hull structures, deck components, and internal fittings, where welds must endure corrosive marine environments and dynamic stresses.

- Pressure Vessels & Boilers: Critical for high-integrity joints in pressure-retaining components, demanding precise control over weld metallurgy and defect-free deposition.

- General Fabrication & Manufacturing: Ideal for general workshop use, producing machinery parts, agricultural equipment, and various metal products.

Key Technical Advantages:

- Superior Arc Stability & Reduced Spatter: The consistent copper coating and precise wire chemistry ensure a smooth, stable arc, minimizing spatter and reducing post-weld cleaning, thereby increasing productivity.

- Excellent Feedability: The smooth, copper-coated surface significantly reduces friction in the welding gun liner, ensuring consistent wire feeding, especially critical for automated and robotic welding systems.

- Enhanced Corrosion Resistance: The copper layer acts as a barrier, protecting the steel core from atmospheric corrosion during storage and handling, extending shelf life and preventing feeding issues caused by rust.

- High Mechanical Properties: Welds produced with our wire exhibit excellent tensile strength, yield strength, and impact toughness, ensuring durable and reliable joints that meet or exceed industry standards.

- Versatile Shielding Gas Compatibility: Optimized for use with both 100% CO2 and Argon/CO2 mixed gases, offering flexibility for various welding applications and operational preferences.

- Consistent Quality: Manufactured under strict ISO 9001 quality management systems, each batch undergoes rigorous testing to guarantee uniformity in chemical composition, mechanical properties, and physical dimensions.

Vendor Comparison: Why Choose Our Copper Coated Welding Wire

In a competitive market, selecting the right supplier for carbon steel welding wire is crucial. Our commitment to quality, innovation, and customer satisfaction sets us apart. Below is a comparative overview highlighting our strengths:

Product & Service Comparison Table

| Feature/Criterion | Our Product/Service | Typical Competitor |

|---|---|---|

| Arc Stability (Robotic/Automated Welding) | Exceptional; minimal fluctuations, ideal for high-speed automation. | Good; may show minor fluctuations, potentially impacting automated consistency. |

| Spatter Level | Very Low; significantly reduces post-weld cleanup time and costs. | Moderate; requires more post-weld cleanup, increasing labor. |

| Wire Feedability | Superior; uniform copper coating and precise winding prevent tangles and jams. | Standard; occasional feeding issues, especially with longer conduits. |

| Copper Coating Uniformity & Adhesion | Excellent; consistent thickness ensures optimal electrical contact and corrosion protection. | Variable; thinner or inconsistent coating can lead to rust and contact issues. |

| Certifications & Compliance | ISO 9001, AWS A5.18, JIS Z 3312, CE; full traceability. | Often meets basic national standards, may lack broader international recognition. |

| Technical Support | Dedicated engineering support, application guidance, and troubleshooting. | Standard customer service; limited deep technical expertise. |

| Customization Options | Flexible for specific diameters, packaging, and chemical compositions. | Generally limited to standard product lines. |

Our company has over 15 years of experience in the manufacturing and supply of welding consumables, building a reputation for reliability and technical excellence. Our robust quality assurance, evidenced by our ISO certifications, ensures every product adheres to the highest standards. We also partner with leading logistics providers to ensure efficient and timely delivery to our global client base.

Customized Solutions and Application Case Studies

Recognizing that standard products may not always meet every unique project requirement, we offer comprehensive customized solutions for our carbon steel welding wire. This flexibility extends to specific wire diameters, precise chemical compositions for particular steel grades, and specialized packaging formats to integrate seamlessly into diverse production environments. Our R&D team works closely with clients to develop tailored solutions, ensuring optimal performance for highly specialized applications.

Application Case Study 1: Large-Scale Pipeline Construction

Client: A leading international energy infrastructure company.

Challenge: The client required a high-performance carbon steel mig wire for automated multi-pass welding of large-diameter oil and gas pipelines. Key challenges included maintaining consistent weld quality in varying environmental conditions (field welding), minimizing spatter to reduce grinding time, and achieving high deposition rates to meet aggressive project timelines.

Solution: We supplied our specialized copper coated carbon steel mig wire (AWS A5.18 ER70S-6 equivalent, 1.2mm diameter) known for its excellent arc stability in spray and pulsed spray transfer modes. Our wire's consistent feedability and low spatter characteristics were crucial for the client's automated welding rigs. We also provided on-site technical support to optimize welding parameters and address any challenges.

Result: The client reported a 15% increase in welding speed due to higher deposition rates and reduced post-weld cleanup, significantly accelerating project completion. Weld integrity tests consistently showed superior mechanical properties and minimal defects, leading to substantial cost savings and enhanced structural reliability of the pipelines. This project validated the wire's performance under rigorous field conditions and its contribution to energy-saving through efficient welding.

Application Case Study 2: Precision Fabrication for Heavy Machinery

Client: A prominent manufacturer of excavators and heavy construction equipment.

Challenge: The client needed a reliable carbon steel tig rod for critical structural components, where weld quality, aesthetics, and fatigue resistance were paramount. The welding involved complex geometries and demanding stress conditions, requiring a wire that offered exceptional control, minimal porosity, and clean, defect-free beads.

Solution: We supplied our precision-cut carbon steel tig rod (AWS A5.18 ER70S-2 equivalent), specifically formulated for TIG welding mild and low-alloy steels. Our rods are known for their cleanliness, excellent puddle control, and consistent melting characteristics, which are vital for intricate, high-quality TIG welds.

Result: The manufacturer achieved consistently high-quality welds, meeting stringent fatigue life requirements for heavy machinery. The superior aesthetic quality of the welds also reduced the need for post-weld grinding and finishing, saving labor costs. Customer feedback highlighted the exceptional ease of use and the significant reduction in weld defects, improving overall product quality and reliability for their heavy equipment.

Frequently Asked Questions (FAQ)

- Q1: What is the primary advantage of copper coating on carbon steel welding wire?

- A1: The copper coating primarily provides enhanced electrical conductivity for stable arc starts, reduces contact tip wear, protects the wire from rust and corrosion during storage, and significantly improves wire feedability by reducing friction in the welding gun liner. These factors collectively contribute to more consistent and higher-quality welds.

- Q2: Can this carbon steel welding wire be used for both MIG/MAG and TIG welding?

- A2: Our copper coated welding wire is primarily designed as a continuous wire for MIG/MAG (GMAW) processes. However, a similar formulation of carbon steel tig rod (cut lengths) is available for TIG (GTAW) applications where precise control and high-quality, aesthetically pleasing welds are required. Please specify your process when inquiring.

- Q3: What shielding gases are recommended for your carbon steel welding wire?

- A3: For MIG/MAG welding, 100% CO2 is commonly used, especially for deeper penetration and cost-effectiveness. Alternatively, an Argon/CO2 mixed gas (e.g., 75% Ar / 25% CO2) is highly recommended for improved arc stability, reduced spatter, and better bead appearance, particularly in automated or robotic applications.

- Q4: What is the typical lead time for large orders?

- A4: Our standard lead time for regular stock items and moderate order volumes is typically 2-4 weeks. For larger, customized orders or specific chemical compositions, the lead time may extend to 4-8 weeks, depending on the complexity and volume. We recommend discussing your specific project timeline with our sales team for an accurate estimate.

Lead Time, Warranty, and Customer Support

Lead Time & Fulfillment

We prioritize efficient order fulfillment to support your production schedules. Our state-of-the-art manufacturing facilities and robust supply chain management enable us to maintain competitive lead times. For standard specifications of copper coated carbon steel welding wire, orders are typically processed and ready for dispatch within 2-4 weeks. Expedited options are available for urgent requirements, subject to production capacity and material availability. We work with trusted global logistics partners to ensure timely and secure delivery to your specified location, complete with tracking and comprehensive documentation.

Warranty Commitments

We stand behind the quality of our products. Our copper coated welding wire for carbon steel comes with a manufacturer's warranty against defects in material and workmanship for a period of 12 months from the date of purchase, provided the product is stored and used in accordance with our recommendations and industry best practices. This warranty covers the wire's chemical composition, mechanical properties, and physical characteristics as per the stated specifications and applicable international standards (e.g., AWS, ISO). Any claims are subject to inspection and verification by our quality assurance team.

Customer Support & After-Sales Service

Our commitment to our clients extends beyond delivery. We offer comprehensive after-sales support, including technical assistance, application guidance, and troubleshooting. Our team of experienced welding engineers is available to provide expert advice on welding parameters, material compatibility, and process optimization to ensure you achieve the best possible results with our products. We also provide full traceability for all our products, ensuring that you have access to detailed batch information and quality certifications whenever needed. For any inquiries or support, please contact us via the details provided on our website: www.steeltoolschina.com.

Conclusion

The selection of welding consumables is a strategic decision that directly impacts operational efficiency, product quality, and long-term cost-effectiveness. Our copper coated carbon steel welding wire is engineered to meet the stringent demands of modern B2B applications, offering a blend of superior performance, consistency, and reliability. By adhering to rigorous manufacturing processes, embracing international quality standards, and providing dedicated customer support, we ensure that our products empower our clients to achieve exceptional welding outcomes across diverse industrial sectors. Partner with us for a dependable supply of high-quality welding solutions that drive productivity and excellence.

References

- American Welding Society. (2010). AWS A5.18/A5.18M: Specification for Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding. Miami, FL: AWS.

- International Organization for Standardization. (2015). ISO 9001: Quality management systems – Requirements. Geneva, Switzerland: ISO.

- Mordor Intelligence. (2023). Welding Consumables Market - Growth, Trends, COVID-19 Impact, and Forecasts (2023 - 2028). Retrieved from Mordor Intelligence website.

- The Welding Institute. (2022). Guidance for selecting MIG/MAG welding wire. Retrieved from TWI Ltd. website.

- Journal of Manufacturing Processes. (2021). Advances in Arc Welding Technologies for Enhanced Productivity and Quality. Elsevier.