Produksiebeskrywing

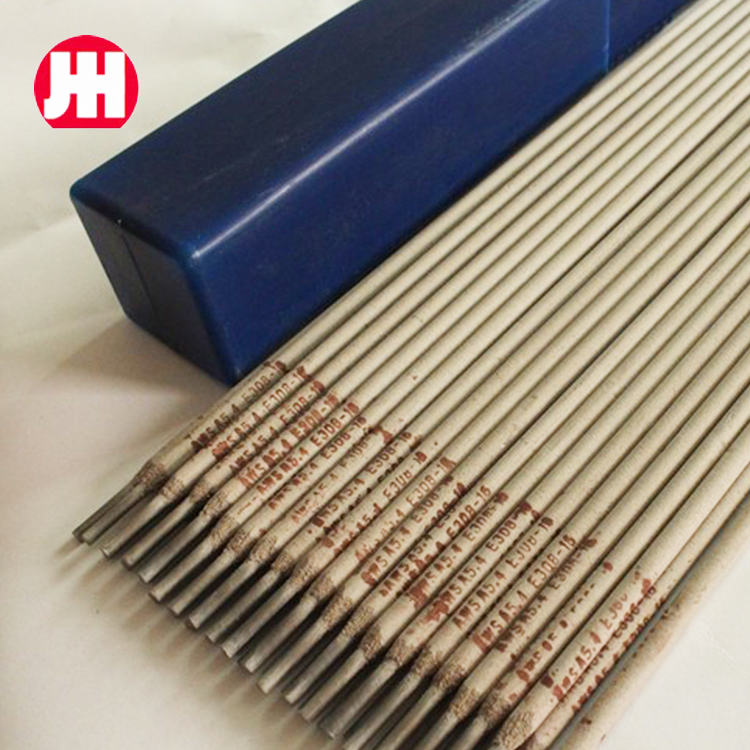

The stainless steel welding electrodes are Suitable for welding the same type of stainless steel, stainless steel lining, different steels (such as Cr19Ni10 and low carbon steel, etc.) as well as gaoluo steel, high manganese steel, etc

APPLICATIONS:

Suitable for welding the same type of stainless steel, stainless steel lining, different steels (such as Cr19Ni10 and low carbon steel, etc.) as well as gaoluo steel, high manganese steel, etc.

KENMERKE:

E309-16 is a Cr23Ni13 stainless steel electrode for rutile skin pressure equipment. Both ac and DC can be used for all position welding. Excellent welding performance. The deposited metal has good crack resistance and oxidation resistance.

AANDAG:

1. Before welding, the electrode shall be baked at 320-350℃ for 1 hour and used as needed.

2. Remove rust, grease, moisture and other impurities before welding.

3. DC power supply is recommended, because the depth of current welding is relatively shallow, the current should not be too large, so as to avoid redness and cracking of the skin.

4. Reduce the heat input as much as possible, and the swing amplitude of the electrode should not be too large.

5. Preheat and keep the temperature between channels below 150℃.

SWEIS POSISIES:

PA, PB, PC, PD, PE, PF

PACKAGING:

5kg/box, 4boxes/carton, 20kgs/carton, 50cartons/pallet. 21MT -26MT per 1X20″ FCL.

OEM/ODM:

We support OEM/ODM and could make packaging accord to your design, please contact us for detail discussion.

Rule inspection:

Welding parts are inspected by the quality inspection department of the manufacturer.

For welds that require radiographic testing, the length of the welds subject to radiographic testing should not be less than 20% of the full length of the welds.

When an impermissible defect in the weld is found, supplementary radiographic testing shall be performed near the defect, and the supplementary radiographic inspection length shall be equal to the length of the radiographically inspected part of the weld. If an unallowable defect is found after supplementary radiographic testing, all welds should be radiographically tested.

For important welding parts, the appearance and geometric shape and size of the weld shall be inspected one by one. In addition to the appearance inspection of welds for general parts, the geometry and dimensions of welds shall also be randomly inspected.

For important parts or important welds of important parts, the requirements for non-destructive testing or sealing test and welding mechanical performance test shall be carried out in accordance with the specifications in the drawings or ordering technical requirements.

CHEMICAL COMPOSITION OF ALL WELDING METAL: (WT. %)

|

Items |

C |

Mn |

En |

S |

P |

In |

Kr |

Ma |

Met |

|

Requirements |

≤0,15 |

0.5-2.5 |

≤1.00 |

≤0,03 |

≤0.04 |

12.0-14.0 |

122.0-25.0 |

≤0,75 |

≤0,75 |

|

Tipiese resultate |

0.060 |

0.89 |

0.69 |

0.010 |

0.025 |

12.50 |

24.05 |

0.10 |

0.08 |

MECHANICAL PROPERTIES OF ALL WELD METAL:

|

Items |

Rm/MPa |

A/% |

| Requirements |

≥550 |

≥25 |

| Tipiese resultate |

600 |

38 |

TYPICAL OPERATING PROCEDURES: (AC OR DC+)

| Diameter (mm) |

2.0 |

2.5 |

3.2 |

4.0 |

5.0 |

| Current (A) |

25-50 |

50-80 |

80-110 |

110-160 |

160-200 |

Spesifikasie & Pakket

2,5 mm (3/32”) x 300/350 mm; 2,5 kg/boks, 20 kg (8 bokse) per karton.

3,2 mm (1/8”) x 350 mm; 5 kg/boks, 20 kg (4 bokse) per karton.

4,0 mm (5/32”) x 400 mm; 5 kg/boks, 20 kg (4 bokse) per karton.

5,0 mm x 450 mm; ander grootte kontak asseblief ons diens.

OEM / ODM-pakket beskikbaar:

NW: 20.00KG, GW: 20.40KG,

ons kan ook verskillende kg-pakkette, plastieksakpakkette doen,

ons kan die pakket druk soos u versoek, ons het professionele ontwerper om die pakketontwerp met u handelsmerk en LOGO te maak.

Produk video

Besoek & Uitstalling

Welkom om ons te besoek vir 'n vriendelike en langtermyn samewerking, vertel ons asseblief jou tydskedule, ons sal vir jou reël. ons sal ook by die verband-uitstallings aansluit, ons kan mekaar op die uitstalling ontmoet. Vriendskap eerste, en besigheid is professioneel, jy kan ons vir altyd vertrou.

Het u die volgende probleme wanneer u die produkte bestel?

1.Is die verskaffer betroubaar?

Ons produseer hierdie produkte meer as 30 jaar, ons adverteer op Alibaba, Made-in-China, nadat u die bestelling geplaas het, wanneer u die produksie wil sien, kan ons vir u video of foto stuur om na te gaan. Ons uitvoerspan het ook meer as 15 jaar ondervinding, ons kan al die probleme oplos wat u in besigheid kan ontmoet. Welkom om ons te besoek.

2.Is die kwaliteit stabiel?

Ons toets lukraak in produksie, en toets versending voor af-fabrieke. Ons het professionele QC-werkers en hoëvlak-toetstoerusting om elke besending van goeie gehalte te verseker.

3.Is die betaling veilig?

Ons kies een van die grootste banke in China, om te verseker dat u betaling in 'n veilige toestand sal aankom, en al die voordeelmaatskappye moet vir hulle die afleweringsdokumentafskrif na die bank stuur vir rekord.

4.Gestuur aflewering?

Normaalweg kan ons versending binne 15 dae reël, as die pakket aanpas, versending kan binne een maand gereël word, onderhandel asseblief met ons kliëntediens, ons sal jou 'n vaste datum vertel nadat ons ons produksie en jou bestelhoeveelheid nagegaan het.

Moet asseblief nie huiwer om ons te kontak nie

Verkoopsbestuurder: Cherry Zhang

Tel: 0086-311-68035766

Faks: 0086-311-68035566

Selfoon: 008613739727566

WhatsApp/Wechat: 008613739727566

E-pos: info@steeltoolschina.com

Stuur navraag