生产说明

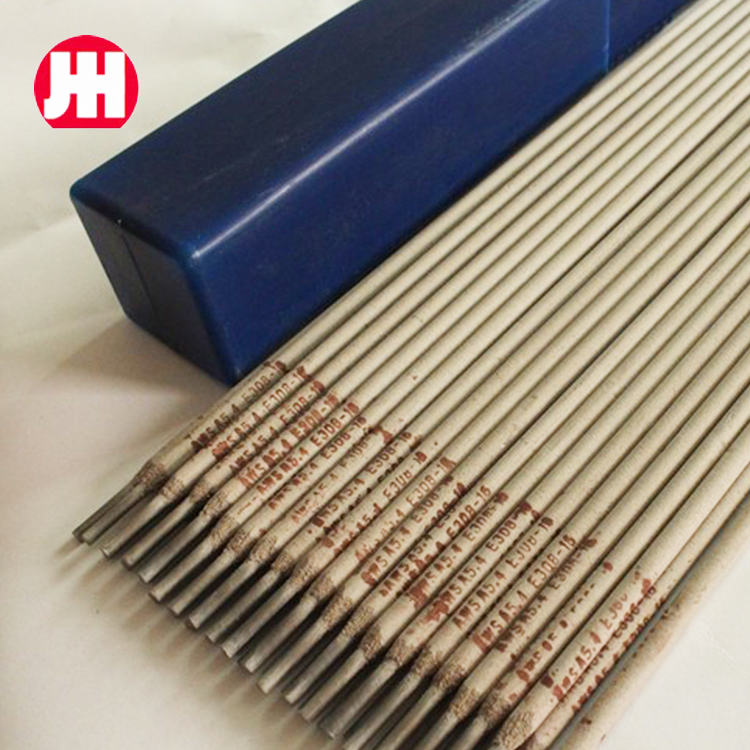

The stainless steel welding electrodes are Suitable for welding the same type of stainless steel, stainless steel lining, different steels (such as Cr19Ni10 and low carbon steel, etc.) as well as gaoluo steel, high manganese steel, etc

APPLICATIONS:

Suitable for welding the same type of stainless steel, stainless steel lining, different steels (such as Cr19Ni10 and low carbon steel, etc.) as well as gaoluo steel, high manganese steel, etc.

特征:

E309-16 is a Cr23Ni13 stainless steel electrode for rutile skin pressure equipment. Both ac and DC can be used for all position welding. Excellent welding performance. The deposited metal has good crack resistance and oxidation resistance.

注意力:

1. Before welding, the electrode shall be baked at 320-350℃ for 1 hour and used as needed.

2. Remove rust, grease, moisture and other impurities before welding.

3. DC power supply is recommended, because the depth of current welding is relatively shallow, the current should not be too large, so as to avoid redness and cracking of the skin.

4. Reduce the heat input as much as possible, and the swing amplitude of the electrode should not be too large.

5. Preheat and keep the temperature between channels below 150℃.

焊接位置:

PA、PB、PC、PD、PE、PF

PACKAGING:

5kg/box, 4boxes/carton, 20kgs/carton, 50cartons/pallet. 21MT -26MT per 1X20″ FCL.

OEM/ODM:

We support OEM/ODM and could make packaging accord to your design, please contact us for detail discussion.

Rule inspection:

Welding parts are inspected by the quality inspection department of the manufacturer.

For welds that require radiographic testing, the length of the welds subject to radiographic testing should not be less than 20% of the full length of the welds.

When an impermissible defect in the weld is found, supplementary radiographic testing shall be performed near the defect, and the supplementary radiographic inspection length shall be equal to the length of the radiographically inspected part of the weld. If an unallowable defect is found after supplementary radiographic testing, all welds should be radiographically tested.

For important welding parts, the appearance and geometric shape and size of the weld shall be inspected one by one. In addition to the appearance inspection of welds for general parts, the geometry and dimensions of welds shall also be randomly inspected.

For important parts or important welds of important parts, the requirements for non-destructive testing or sealing test and welding mechanical performance test shall be carried out in accordance with the specifications in the drawings or ordering technical requirements.

CHEMICAL COMPOSITION OF ALL WELDING METAL: (WT. %)

|

Items |

C |

锰 |

和 |

S |

P |

在 |

铬 |

莫 |

和 |

|

Requirements |

≤0.15 |

0.5-2.5 |

≤1.00 |

≤0.03 |

≤0.04 |

12.0-14.0 |

122.0-25.0 |

≤0.75 |

≤0.75 |

|

典型结果 |

0.060 |

0.89 |

0.69 |

0.010 |

0.025 |

12.50 |

24.05 |

0.10 |

0.08 |

MECHANICAL PROPERTIES OF ALL WELD METAL:

|

Items |

室/兆帕 |

A/% |

| Requirements |

≥550 |

≥25 |

| 典型结果 |

600 |

38 |

TYPICAL OPERATING PROCEDURES: (AC OR DC+)

| Diameter (mm) |

2.0 |

2.5 |

3.2 |

4.0 |

5.0 |

| Current (A) |

25-50 |

50-80 |

80-110 |

110-160 |

160-200 |

规格及包装

2.5 毫米(3/32 英寸)× 300/350 毫米; 2.5公斤/箱,20公斤(8箱)/箱。

3.2 毫米(1/8 英寸)x 350 毫米; 5公斤/箱,20公斤(4箱)/箱。

4.0 毫米(5/32 英寸)x 400 毫米; 5公斤/箱,20公斤(4箱)/箱。

5.0毫米×450毫米;其他尺寸请联系我们的服务。

提供 OEM/ODM 封装:

净重:20.00KG,毛重:20.40KG,

我们还可以做不同公斤的包装,塑料袋包装,

我们可以根据您的要求打印包装,我们有专业的设计师来制作带有您的品牌和标志的包装设计。

产品视频

参观展览

欢迎您来访,进行友好和长期的合作,请告诉我们您的时间安排,我们将为您安排。我们也会参加相关的展会,我们可以在展会上见面。友谊第一,生意专业,您可以永远信赖我们。

您在订购产品时是否遇到以下困扰?

1.供应商可靠吗?

我们生产这种产品已有 30 多年的历史,我们在阿里巴巴、中国制造上做广告,在您下订单后,每当您想查看生产时,我们可以向您发送视频或图片进行检查。我们的出口团队也拥有超过15年的经验,我们可以解决您在业务中可能遇到的所有问题。欢迎光临。

2.质量稳定吗?

我们在生产中进行随机测试,并在出厂前测试发货。我们拥有专业的QC人员和高水平的测试设备,以确保每批货物的良好质量。

3.付款安全吗?

我们选择中国最大的银行之一,以确保您的付款能够安全到达,所有受益公司都必须将货运单据副本发送给银行备案。

4.发货交付?

通常我们可以在 15 天内安排发货,如果定制包装,可以在 1 个月内安排发货,请与我们的客服协商,我们会在检查我们的生产和您的订单数量后告诉您一个确定的日期。

请随时联系我们

销售经理:张樱

电话:0086-311-68035766

传真:0086-311-68035566

手机:008613739727566

WhatsApp/微信:008613739727566

邮箱:info@steeltoolschina.com

发送询问