Opis proizvodnje

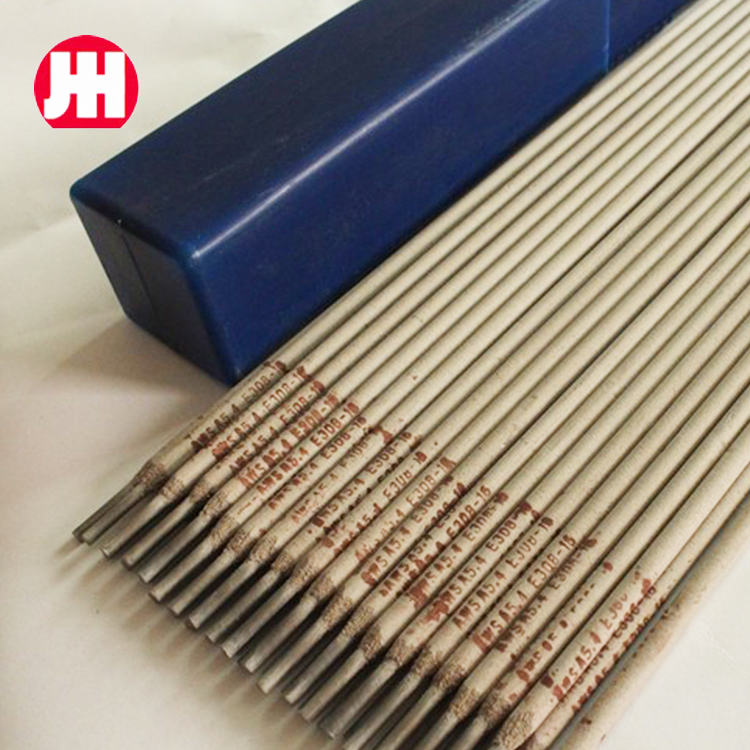

The stainless steel welding electrodes are Suitable for welding the same type of stainless steel, stainless steel lining, different steels (such as Cr19Ni10 and low carbon steel, etc.) as well as gaoluo steel, high manganese steel, etc

APPLICATIONS:

Suitable for welding the same type of stainless steel, stainless steel lining, different steels (such as Cr19Ni10 and low carbon steel, etc.) as well as gaoluo steel, high manganese steel, etc.

KARAKTERISTIKE:

E309-16 is a Cr23Ni13 stainless steel electrode for rutile skin pressure equipment. Both ac and DC can be used for all position welding. Excellent welding performance. The deposited metal has good crack resistance and oxidation resistance.

PAŽNJA:

1. Before welding, the electrode shall be baked at 320-350℃ for 1 hour and used as needed.

2. Remove rust, grease, moisture and other impurities before welding.

3. DC power supply is recommended, because the depth of current welding is relatively shallow, the current should not be too large, so as to avoid redness and cracking of the skin.

4. Reduce the heat input as much as possible, and the swing amplitude of the electrode should not be too large.

5. Preheat and keep the temperature between channels below 150℃.

POZICIJE ZA ZAVARIVANJE:

PA, PB, PC, PD, PE, PF

PACKAGING:

5kg/box, 4boxes/carton, 20kgs/carton, 50cartons/pallet. 21MT -26MT per 1X20″ FCL.

OEM/ODM:

We support OEM/ODM and could make packaging accord to your design, please contact us for detail discussion.

Rule inspection:

Welding parts are inspected by the quality inspection department of the manufacturer.

For welds that require radiographic testing, the length of the welds subject to radiographic testing should not be less than 20% of the full length of the welds.

When an impermissible defect in the weld is found, supplementary radiographic testing shall be performed near the defect, and the supplementary radiographic inspection length shall be equal to the length of the radiographically inspected part of the weld. If an unallowable defect is found after supplementary radiographic testing, all welds should be radiographically tested.

For important welding parts, the appearance and geometric shape and size of the weld shall be inspected one by one. In addition to the appearance inspection of welds for general parts, the geometry and dimensions of welds shall also be randomly inspected.

For important parts or important welds of important parts, the requirements for non-destructive testing or sealing test and welding mechanical performance test shall be carried out in accordance with the specifications in the drawings or ordering technical requirements.

CHEMICAL COMPOSITION OF ALL WELDING METAL: (WT. %)

|

Items |

C |

Mn |

I |

S |

P |

U |

Kr |

Mo |

S |

|

Requirements |

≤0,15 |

0.5-2.5 |

≤1.00 |

≤0,03 |

≤0.04 |

12.0-14.0 |

122.0-25.0 |

≤0,75 |

≤0,75 |

|

Tipični rezultati |

0.060 |

0.89 |

0.69 |

0.010 |

0.025 |

12.50 |

24.05 |

0.10 |

0.08 |

MECHANICAL PROPERTIES OF ALL WELD METAL:

|

Items |

Rm/MPa |

A/% |

| Requirements |

≥550 |

≥25 |

| Tipični rezultati |

600 |

38 |

TYPICAL OPERATING PROCEDURES: (AC OR DC+)

| Diameter (mm) |

2.0 |

2.5 |

3.2 |

4.0 |

5.0 |

| Current (A) |

25-50 |

50-80 |

80-110 |

110-160 |

160-200 |

Specifikacija i paket

2,5 mm (3/32”) x 300/350 mm; 2,5 kg/kutija, 20 kg (8 kutija) po kartonu.

3,2 mm (1/8”) x 350 mm; 5 kg/kutija, 20 kg (4 kutije) po kartonu.

4,0 mm (5/32”) x 400 mm; 5 kg/kutija, 20 kg (4 kutije) po kartonu.

5,0 mm x 450 mm; druge veličine kontaktirajte našu službu.

Dostupan OEM/ODM paket:

NW: 20,00 KG, GW: 20,40 KG,

također možemo napraviti različita pakiranja kg, pakiranje plastičnih vrećica,

možemo ispisati paket prema vašim zahtjevima, imamo profesionalnog dizajnera koji će napraviti dizajn paketa s vašim brendom i LOGO-om.

Video o proizvodu

Posjet i izložba

Dobrodošli da nas posjetite radi prijateljske i dugoročne suradnje, recite nam svoj vremenski raspored, dogovorit ćemo se za vas. također ćemo se pridružiti povezanim izložbama, možemo se upoznati na izložbi. Prijateljstvo na prvom mjestu, a posao je profesionalan, možete nam vjerovati zauvijek.

Imate li sljedeće probleme prilikom naručivanja proizvoda?

1. Je li dobavljač pouzdan?

Proizvodimo ove proizvode više od 30 godina, oglašavamo na Alibabi, Made-in-China, nakon što naručite, kad god želite vidjeti proizvodnju, možemo vam poslati video ili sliku da provjerite. Naš izvozni tim također ima više od 15 godina iskustva, možemo riješiti sve probleme s kojima se možete susresti u poslu. Dobrodošli da nas posjetite.

2. Je li kvaliteta stabilna?

Testiramo nasumično u proizvodnji i testiramo isporuku prije tvorničke radnje. Imamo profesionalne radnike za kontrolu kvalitete i opremu za testiranje visoke razine kako bismo osigurali dobru kvalitetu svake pošiljke.

3. Je li plaćanje sigurno?

Odabrali smo jednu od najvećih banaka u Kini, kako bismo osigurali da će vaša uplata stići u sigurnom stanju, a sve korisničke tvrtke moraju poslati kopiju dokumenta o otpremnici banci radi evidencije.

4. Dostava pošiljke?

Obično možemo dogovoriti isporuku za 15 dana, ako prilagodite paket, isporuka se može dogovoriti za mjesec dana, molimo pregovarajte s našom korisničkom službom, reći ćemo vam točan datum nakon što provjerite našu proizvodnju i količinu narudžbe.

Molimo nemojte se ustručavati kontaktirati nas

Voditeljica prodaje: Cherry Zhang

Tel: 0086-311-68035766

Faks: 0086-311-68035566

Mobitel: 008613739727566

WhatsApp/Wechat: 008613739727566

E-pošta: info@steeltoolschina.com

Pošaljite upit